Understanding The Dysprosium Supply Chain And Geopolitical Risks

Table of Contents

Geographical Concentration of Dysprosium Production

The dominance of China in the dysprosium market casts a long shadow over the global supply chain. China's control over mining and processing significantly outweighs that of any other nation, creating substantial geopolitical dependencies and vulnerabilities for nations reliant on this critical rare earth element for their technological advancements.

-

China's overwhelming share: China's share of global dysprosium production is estimated to be over 80%, a figure that underscores the precariousness of the current supply situation. This concentration makes the global economy heavily reliant on a single nation's political and economic stability.

-

Geopolitical dependencies: This extreme concentration creates significant risks. Any political instability in China, trade disputes involving China, or changes in Chinese export policies could trigger severe disruptions to the global dysprosium supply, impacting numerous industries.

-

Limited diversification: While countries like Australia and the USA possess dysprosium reserves, their current production levels are far below those of China. Increasing these outputs is crucial to diversifying the dysprosium supply chain and mitigating the risks inherent in over-reliance on a single source.

-

Potential for supply chain disruptions: The potential for disruptions is amplified by the fact that dysprosium is not readily substituted in many of its applications. This lack of readily available alternatives makes disruptions particularly damaging. The current situation necessitates a proactive approach to reducing reliance on China's dominance in dysprosium production.

The Dysprosium Supply Chain: From Mine to Magnet

The dysprosium supply chain is a complex process involving several stages, each with its own challenges and potential bottlenecks. Understanding these stages is crucial to identifying potential points of failure and developing strategies to mitigate supply chain risks.

-

Mining and extraction: Dysprosium ore is extracted from the earth through various mining techniques, often involving significant environmental considerations. These considerations can influence costs and overall production volumes.

-

Refining and separation: This stage involves separating dysprosium from other rare earth elements present in the ore. This process is technologically challenging and energy-intensive, further complicating the supply chain. Improved refining techniques are needed to enhance efficiency and reduce environmental impact.

-

Manufacturing of dysprosium-based magnets: Dysprosium is a critical component in high-performance magnets used in various technologies. The manufacturing of these magnets is a specialized process requiring sophisticated technology and expertise.

-

Integration into end products: These dysprosium-based magnets are integrated into a wide range of end products, including wind turbines, electric vehicles, and various electronics. This final stage highlights the widespread applications of this critical rare earth element and the far-reaching impact of supply chain disruptions.

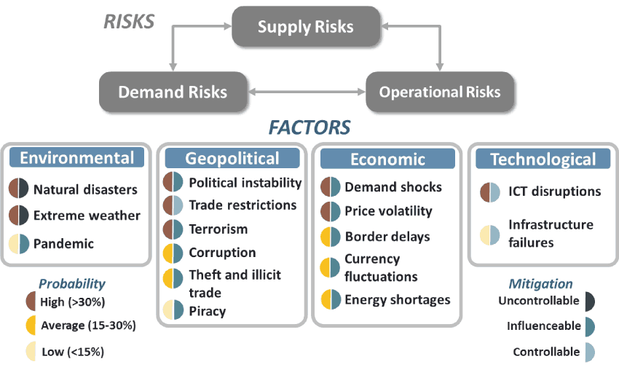

Geopolitical Risks and Diversification Strategies

The current structure of the dysprosium supply chain presents several significant geopolitical risks that require immediate attention. A diversified and resilient supply chain is essential to ensure the long-term availability of this critical material.

-

Over-reliance on a single producer: The heavy reliance on China for dysprosium presents a substantial geopolitical risk. Any disruption to the supply from China could have significant economic consequences globally.

-

Trade wars and sanctions: Geopolitical tensions and trade disputes involving China could lead to export restrictions or sanctions, causing dramatic price increases and supply shortages.

-

Political instability: Political instability in dysprosium-producing regions can disrupt mining operations and processing, impacting the global supply.

-

Diversification is crucial: Diversifying supply sources by investing in exploration and mining in other countries is critical for mitigating these risks. International collaborations and strategic partnerships are essential to achieving this diversification.

-

Alternative materials and recycling: Exploring alternative magnet materials and developing efficient recycling technologies for dysprosium are crucial long-term strategies. These initiatives reduce dependence on primary mining and lessen environmental impacts.

The Role of Technology in Mitigating Risks

Technological advancements play a vital role in reducing reliance on China's dominant position in the dysprosium market and improving the overall resilience of the supply chain.

-

Improved mining and extraction techniques: More efficient and environmentally friendly mining techniques can increase production while reducing the environmental footprint.

-

More efficient separation and purification methods: Advances in separation and purification technologies can lower costs and increase the yield of dysprosium from ore.

-

Development of alternative magnet materials: Research into alternative magnet materials that do not rely on dysprosium is crucial to reducing dependence on this single element.

-

Recycling and reuse of dysprosium: Developing robust recycling processes to recover dysprosium from end-of-life products is essential for resource conservation and supply chain security.

Conclusion

The vulnerabilities inherent in the current dysprosium supply chain, particularly its geographical concentration and geopolitical dependencies, present significant challenges for industries relying on this crucial rare earth element. Diversification of supply sources, technological advancements in extraction and processing, and the exploration of alternative materials are critical to mitigating these risks. Understanding the intricacies of the dysprosium supply chain and proactively addressing these vulnerabilities is paramount to ensuring the stable and sustainable supply of this essential element for future technological advancements. Further research and investment in secure and diversified dysprosium supply chains are urgently needed to secure the future of green technologies and advanced manufacturing.

Featured Posts

-

Capital Summertime Ball 2025 Ticket Purchase Guide

Apr 29, 2025

Capital Summertime Ball 2025 Ticket Purchase Guide

Apr 29, 2025 -

Legal Implications Of Selling Banned Chemicals On E Bay Section 230s Limits

Apr 29, 2025

Legal Implications Of Selling Banned Chemicals On E Bay Section 230s Limits

Apr 29, 2025 -

Johnny Damon Supports Trumps Stance On Pete Roses Hall Of Fame Eligibility

Apr 29, 2025

Johnny Damon Supports Trumps Stance On Pete Roses Hall Of Fame Eligibility

Apr 29, 2025 -

The Russian Militarys Moves Why Europe Is Concerned

Apr 29, 2025

The Russian Militarys Moves Why Europe Is Concerned

Apr 29, 2025 -

Is The Venture Capital Secondary Market Right For You

Apr 29, 2025

Is The Venture Capital Secondary Market Right For You

Apr 29, 2025