Is It Really Worth It? The Economics Of All-American Manufacturing

Table of Contents

- The High Cost of Domestic Production

- Labor Costs

- Raw Material Sourcing

- Regulatory Compliance and Taxes

- The Benefits of All-American Manufacturing

- Brand Reputation and Consumer Preference

- Job Creation and Economic Growth

- Enhanced Supply Chain Security and Resilience

- Finding the Right Balance: Strategies for Competitive All-American Manufacturing

- Technological Innovation and Automation

- Government Incentives and Support

- Focusing on Niche Markets and Specialized Products

- The Verdict on All-American Manufacturing

The High Cost of Domestic Production

Producing goods domestically presents significant economic challenges. The higher cost of all-American manufacturing stems from several key factors:

Labor Costs

American labor costs are significantly higher than in many other countries. This difference directly impacts production costs.

- Industries with High Labor Costs: Aerospace, pharmaceuticals, and advanced electronics are examples of sectors with particularly high labor expenses.

- Hourly Wage Comparisons: The average hourly wage for manufacturing workers in the US is substantially higher than in countries like China, Vietnam, or Mexico. This disparity significantly impacts the price competitiveness of domestically manufactured goods.

- Impact of Unions: Unionized workplaces often command higher wages and benefits, further increasing labor costs for all-American manufacturing.

These elevated "American labor costs" present a considerable challenge to maintaining price competitiveness in the global market.

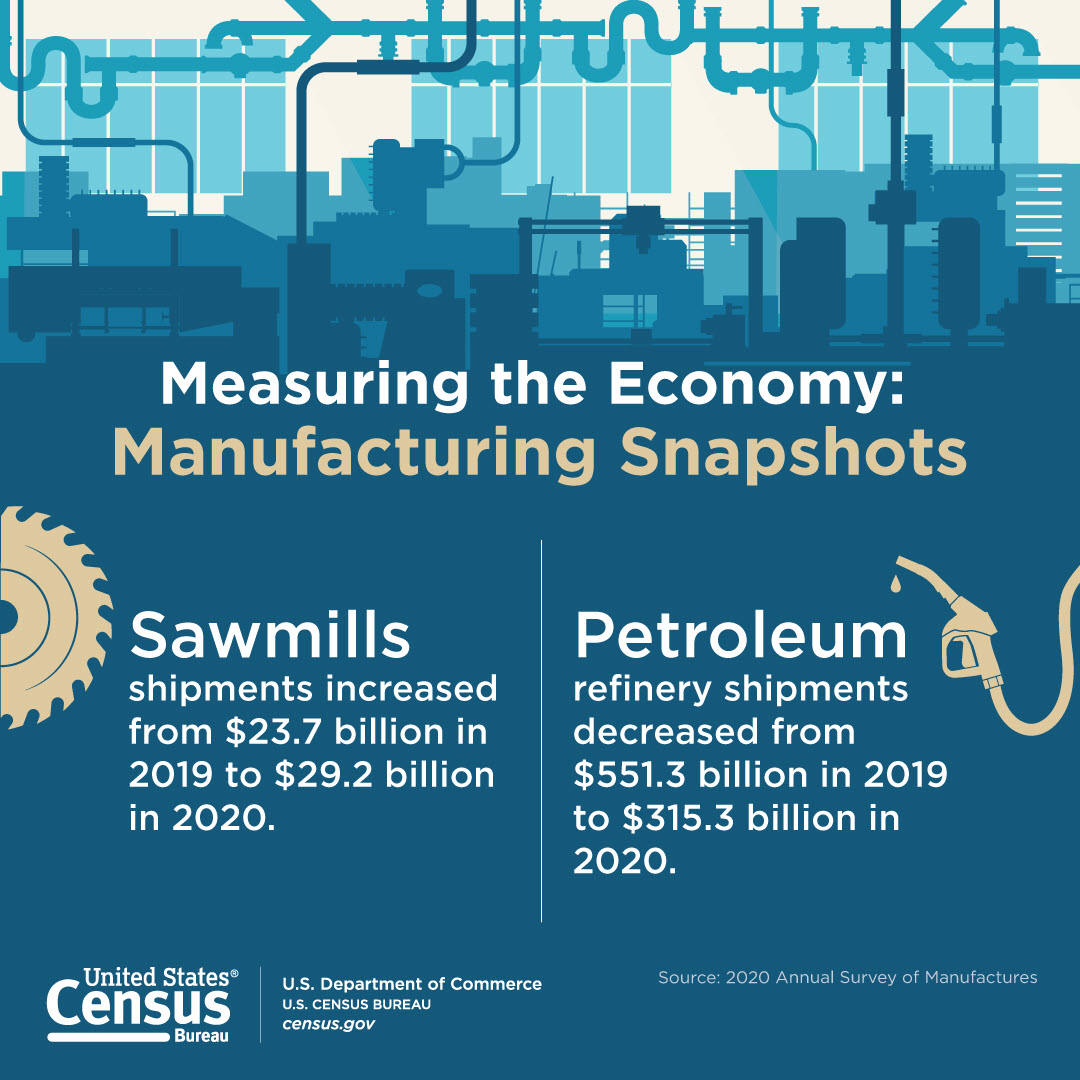

Raw Material Sourcing

Sourcing raw materials domestically can also increase costs. While supporting domestic suppliers is beneficial for the economy, it often means paying more for materials than sourcing them globally.

- Higher Domestic Costs for Certain Materials: Certain raw materials, like some rare earth minerals or specialized lumber, are either not produced in the US or are significantly more expensive to source domestically.

- Transportation Costs: Moving raw materials across the US adds to the overall cost, especially for bulky or heavy materials.

- Reliance on Imports: Even with efforts to increase domestic sourcing, the US remains reliant on imported raw materials for various manufacturing processes, impacting supply chain stability.

- Supply Chain Disruptions: Dependence on global supply chains for raw materials exposes domestic manufacturers to disruptions caused by geopolitical instability, natural disasters, or pandemics.

Regulatory Compliance and Taxes

Stringent US regulations and taxes add further complexity and expense to domestic manufacturing.

- Environmental Regulations: Meeting environmental standards, including emissions controls and waste disposal, adds to the operational costs of American factories.

- Safety Standards: Ensuring workplace safety and adhering to strict safety regulations increases both capital and operational expenditure.

- Corporate Taxes: The US corporate tax rate, while recently reduced, remains relatively high compared to some other nations.

- Tariffs: Tariffs on imported goods can protect domestic industries but also raise input costs for manufacturers that rely on imported components.

The Benefits of All-American Manufacturing

Despite the higher costs, all-American manufacturing offers several compelling advantages that often outweigh the price differences for consumers and the nation as a whole.

Brand Reputation and Consumer Preference

"Made in USA" branding carries significant weight with many consumers.

- Increased Brand Loyalty: Consumers often associate "Made in America" with higher quality and increased durability, leading to greater brand loyalty.

- Higher Perceived Quality: Domestically manufactured goods are frequently perceived as superior in quality and craftsmanship, justifying premium pricing.

- Willingness to Pay a Premium: Many consumers are willing to pay more for products carrying the "Made in USA" label, reflecting a preference for supporting domestic jobs and production.

- Marketing Advantages: The "Made in USA" label serves as a powerful marketing tool, helping to differentiate products and command higher prices.

Job Creation and Economic Growth

Domestic manufacturing directly and indirectly creates jobs and stimulates economic growth.

- Economic Multipliers: Manufacturing jobs have a substantial economic multiplier effect, generating additional jobs in supporting industries like transportation, logistics, and retail.

- Local Community Benefits: Manufacturing plants contribute significantly to the economic well-being of local communities through job creation, tax revenue, and investment.

- Reduction in Trade Deficits: Increased domestic manufacturing reduces reliance on imported goods, contributing to a smaller trade deficit for the US. Increased exports of American-made goods further contribute to a positive trade balance.

Enhanced Supply Chain Security and Resilience

All-American manufacturing enhances supply chain security and reduces vulnerability to global disruptions.

- Mitigation of Geopolitical Risks: Reduced dependence on foreign suppliers mitigates risks associated with geopolitical instability and international conflicts.

- Reduced Vulnerability to Disruptions: Domestic production offers greater resilience to supply chain disruptions caused by natural disasters, pandemics, or other unforeseen events.

- Faster Response Times: Shorter lead times and easier communication within a domestic supply chain allow for faster response to changing market demands and customer needs.

Finding the Right Balance: Strategies for Competitive All-American Manufacturing

Successfully navigating the challenges of all-American manufacturing requires a multi-pronged approach.

Technological Innovation and Automation

Adopting advanced technologies is crucial for reducing labor costs and improving efficiency.

- Robotics and AI: Investing in automation technologies like robotics and artificial intelligence can significantly reduce reliance on manual labor, lowering production costs.

- Automation Solutions: Implementing various automation solutions across the manufacturing process improves efficiency and reduces waste.

- Industry 4.0: Embracing Industry 4.0 technologies, such as the Internet of Things (IoT) and advanced data analytics, can lead to significant improvements in productivity and cost-effectiveness.

Government Incentives and Support

Government policies play a critical role in supporting domestic manufacturing.

- Tax Breaks and Subsidies: Targeted tax incentives and subsidies can make domestic production more attractive to businesses.

- Grants for Research and Development: Government funding for research and development in advanced manufacturing technologies can drive innovation and competitiveness.

- Infrastructure Investments: Investments in infrastructure, including transportation networks and reliable energy sources, are essential for supporting manufacturing operations.

- Trade Policies: Strategic trade policies, including tariffs and trade agreements, can protect domestic industries from unfair competition.

Focusing on Niche Markets and Specialized Products

Concentrating on high-value, specialized products offers a path to competitiveness.

- High-Skill Manufacturing: Focusing on products requiring high levels of skill and expertise can command higher prices and reduce reliance on low-cost labor.

- Specialized Components: Manufacturing specialized components for larger industries can establish a strong niche market.

- Premium Goods: Producing high-quality, premium goods that command a higher price point can offset the higher costs of domestic production.

The Verdict on All-American Manufacturing

All-American manufacturing faces significant cost challenges related to labor, raw materials, and regulatory compliance. However, the benefits – including brand reputation, job creation, and supply chain resilience – are equally substantial. The key to success lies in finding the right balance, leveraging technological advancements, securing government support, and focusing on niche markets and specialized products. This approach allows American businesses to compete effectively in the global marketplace while maintaining the vital economic and social advantages of domestic production.

Learn more about the benefits and challenges of All-American Manufacturing and make informed choices when supporting domestic businesses. Explore the opportunities in all-American manufacturing and discover how you can contribute to its growth.

Tylor Megill And The Mets Analyzing His Recent Success

Tylor Megill And The Mets Analyzing His Recent Success

The Ccp United Fronts Minnesota Operations Unveiling The Details

The Ccp United Fronts Minnesota Operations Unveiling The Details

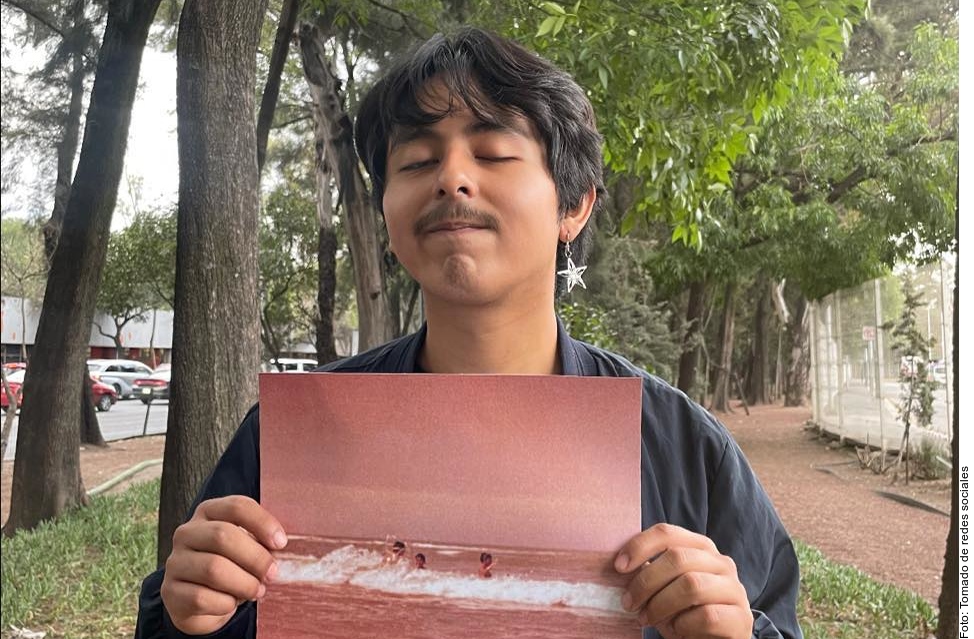

The Inspiring Tale Of Macario Martinez A Street Sweepers Path To National Prominence

The Inspiring Tale Of Macario Martinez A Street Sweepers Path To National Prominence

Kentuckys Severe Weather Preparedness A Focus For Nws Awareness Week

Kentuckys Severe Weather Preparedness A Focus For Nws Awareness Week

Dysprosium The Rare Earth Element Disrupting The Ev Industry

Dysprosium The Rare Earth Element Disrupting The Ev Industry