Dysprosium: The Rare Earth Element Disrupting The EV Industry

Table of Contents

Dysprosium's Unique Properties and Applications in Electric Vehicles

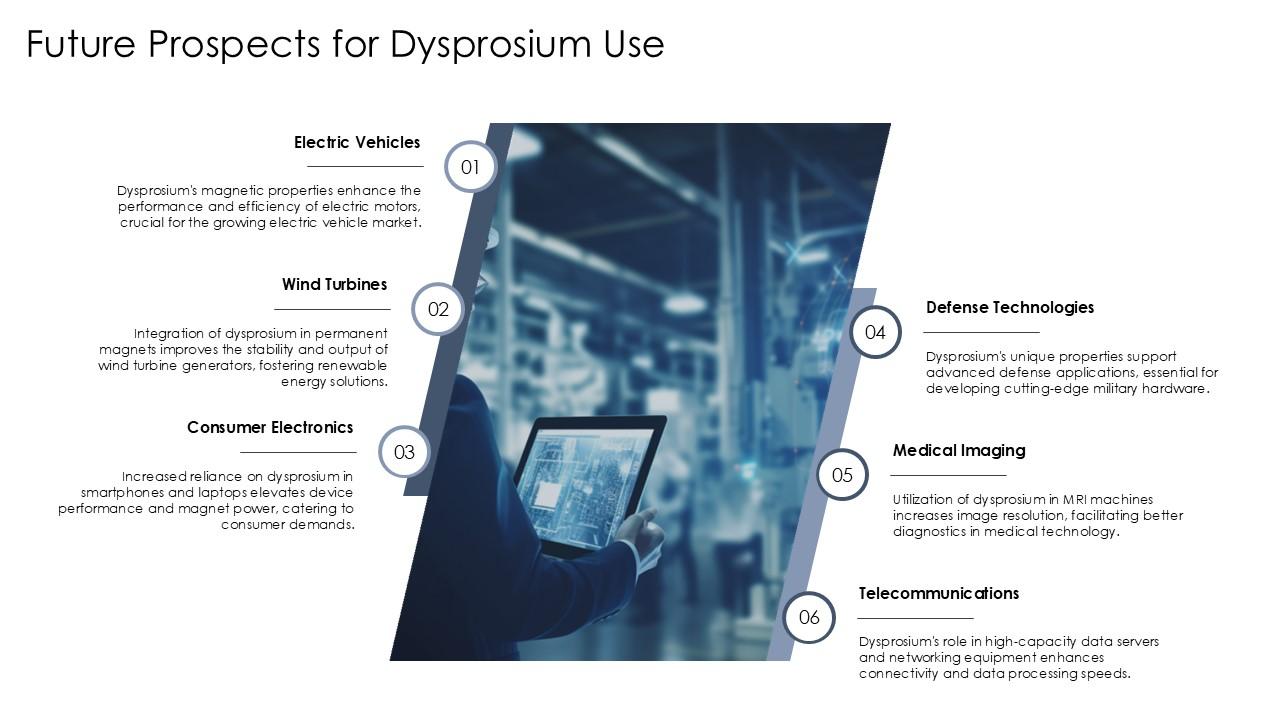

Dysprosium's unique magnetic properties are what make it so crucial for the EV industry. Its high magnetic anisotropy and Curie temperature contribute significantly to the performance of powerful and efficient electric motors.

The Importance of Dysprosium in Neodymium Magnets

Dysprosium is a key component in neodymium magnets, which are exceptionally strong permanent magnets. These magnets are essential for high-performance electric vehicle motors because they allow for:

- High Torque Output: Dysprosium enhances the magnet's ability to generate significant torque, essential for acceleration and hill climbing in EVs.

- High Efficiency: The strength and stability of dysprosium-enhanced neodymium magnets contribute to the overall efficiency of the motor, maximizing energy usage.

- Compact Size: The high magnetic flux density of these magnets allows for smaller and lighter motor designs, leading to improved vehicle design and weight reduction.

Specific EV components relying heavily on dysprosium magnets include:

- Traction motors (responsible for propelling the vehicle)

- Generators (for regenerative braking)

- Power steering systems

Improving Motor Performance and Efficiency

The addition of dysprosium to neodymium magnets significantly improves the performance and efficiency of EV motors. This translates to several key benefits:

- Increased Driving Range: Higher efficiency translates directly into extended driving range on a single charge. Studies have shown that optimized dysprosium usage can increase range by up to 15%.

- Reduced Energy Consumption: Dysprosium's contribution to motor efficiency reduces the overall energy consumed to achieve the same level of performance.

- Improved Thermal Stability: Dysprosium helps maintain the magnet's strength at higher temperatures, crucial for consistent motor performance even under strenuous conditions.

Comparison with Alternative Materials

While dysprosium is currently the preferred choice, researchers are exploring alternative materials for neodymium magnets. However, these alternatives often come with trade-offs:

- Samarium-Cobalt Magnets: Offer good performance but are more expensive and less powerful than dysprosium-enhanced neodymium magnets.

- Ferrite Magnets: Cheaper and more readily available, but significantly weaker, requiring larger and heavier motors.

The Challenges of Dysprosium Supply and Demand

The EV industry's reliance on dysprosium presents significant challenges related to supply, demand, and environmental impact.

Geopolitical Concerns and Supply Chain Risks

Dysprosium mining and processing are geographically concentrated, primarily in China. This concentration creates significant geopolitical risks:

- Supply Chain Vulnerabilities: Disruptions in these regions could severely impact the global supply of dysprosium, hindering EV production.

- Price Manipulation: The concentrated supply makes the market vulnerable to price manipulation and fluctuations.

- Trade Disputes: International trade tensions can disrupt the supply chain and significantly impact the availability and price of dysprosium.

Environmental Impact of Dysprosium Mining

The extraction and processing of dysprosium have environmental consequences:

- Waste Generation: Mining activities generate significant waste, impacting surrounding ecosystems.

- Water Pollution: Processing dysprosium can lead to water contamination if not managed properly.

- Habitat Destruction: Mining operations can cause habitat destruction and biodiversity loss.

Price Volatility and Market Fluctuations

The price of dysprosium has historically been volatile, creating uncertainty for EV manufacturers:

- Unpredictable Costs: Fluctuations in dysprosium prices make it difficult to accurately forecast manufacturing costs and plan for future production.

- Investment Risks: Price volatility introduces significant financial risks for companies investing in EV technology.

Innovations and Strategies to Mitigate Dysprosium Dependence

Addressing the challenges associated with dysprosium requires a multifaceted approach:

Developing More Efficient Magnet Designs

Research is focused on optimizing magnet designs to minimize dysprosium usage while maintaining performance:

- Advanced Alloying Techniques: Developing new alloys that enhance the magnetic properties with lower dysprosium content.

- Improved Manufacturing Processes: Optimizing manufacturing processes to reduce waste and improve material utilization.

Recycling and Resource Recovery

Recycling end-of-life EVs is crucial for securing a sustainable supply of dysprosium:

- Magnet Separation Technologies: Developing efficient methods to separate and recover magnets from discarded vehicles.

- Hydrometallurgical Processes: Utilizing hydrometallurgical processes to extract and purify dysprosium from recycled magnets.

Exploring Alternative Magnet Technologies

Research into alternative magnet technologies is essential for reducing reliance on rare earth elements:

- High-Temperature Superconducting Magnets: While still under development, these magnets offer the potential for significantly higher performance and efficiency compared to current technologies.

- Ferrite Magnets with Enhanced Properties: Improving the performance characteristics of ferrite magnets to make them a more viable alternative.

Conclusion: Securing the Future of Electric Vehicles with Sustainable Dysprosium Management

The widespread adoption of electric vehicles hinges on securing a sustainable supply of crucial materials like dysprosium. Understanding dysprosium's role, the challenges of its supply chain, and the ongoing efforts towards sustainable dysprosium solutions is critical. By investing in efficient magnet designs, robust recycling infrastructure, and exploring alternative magnet technologies, we can pave the way for a future where electric vehicles are both efficient and environmentally responsible. Learn more about the role of dysprosium and contribute to the development of sustainable dysprosium solutions for the future of electric vehicles.

Featured Posts

-

Finding Capital Summertime Ball 2025 Tickets The Ultimate Guide

Apr 29, 2025

Finding Capital Summertime Ball 2025 Tickets The Ultimate Guide

Apr 29, 2025 -

One Plus 13 R And Pixel 9a Specs Features And Price Comparison Review

Apr 29, 2025

One Plus 13 R And Pixel 9a Specs Features And Price Comparison Review

Apr 29, 2025 -

Concern Grows For Missing British Paralympian Last Contact Made Over A Week Ago In Las Vegas

Apr 29, 2025

Concern Grows For Missing British Paralympian Last Contact Made Over A Week Ago In Las Vegas

Apr 29, 2025 -

Nyt Spelling Bee February 28 2025 Solutions Answers And Pangram

Apr 29, 2025

Nyt Spelling Bee February 28 2025 Solutions Answers And Pangram

Apr 29, 2025 -

Jeff Goldblums Best Performances A Career Overview

Apr 29, 2025

Jeff Goldblums Best Performances A Career Overview

Apr 29, 2025