Eramet's EraLow: Driving Innovation In Low-Carbon Manganese Alloys For Steel

Table of Contents

The Environmental Impact of Traditional Manganese Alloys

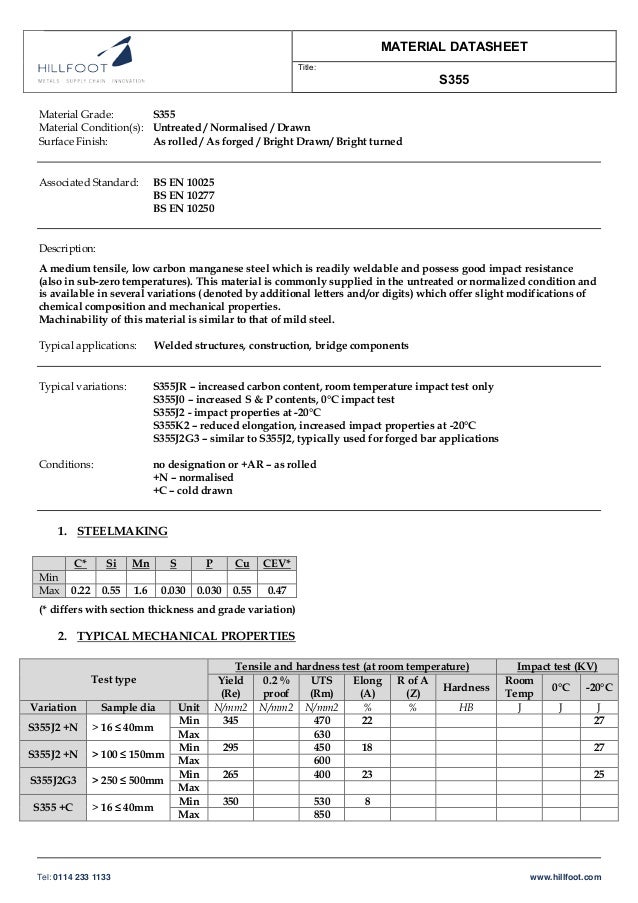

Traditional manganese alloy production significantly contributes to the steel industry's substantial carbon emissions. The high carbon footprint stems from energy-intensive processes and the inherent carbon content of conventional alloys.

High Carbon Footprint of Conventional Steelmaking

Conventional steelmaking relies on processes that generate considerable CO2 emissions:

- Smelting: The high-temperature smelting process requires vast amounts of energy, primarily from fossil fuels, leading to significant CO2 release.

- Energy Consumption: The overall energy intensity of traditional manganese alloy production contributes substantially to greenhouse gas emissions.

- Carbon-Intensive Raw Materials: The raw materials used in traditional methods often contain high levels of carbon, further increasing emissions.

Studies indicate that traditional manganese alloy production accounts for a considerable percentage of the overall carbon footprint of steel production – a figure that is under increasing scrutiny due to stricter environmental regulations globally. These regulations, including carbon taxes and emission trading schemes, are forcing the steel industry to seek more sustainable alternatives.

eraLow: A Game-Changer in Sustainable Steel Production

Eramet's eraLow range represents a significant leap forward in sustainable steel production. This innovative range of low-carbon manganese alloys utilizes advanced processes to drastically reduce the environmental impact compared to traditional methods.

Reduced Carbon Emissions through Innovative Processes

Eramet's eraLow alloys are produced using cutting-edge technologies designed to minimize carbon emissions:

- Electromobility: Increased reliance on electric arc furnaces, powered by renewable energy sources, significantly reduces reliance on fossil fuels.

- Improved Energy Efficiency: Optimized processes and advanced furnace designs minimize energy consumption throughout the production chain.

- Carbon Capture and Utilization (CCU) Technologies: Eramet is actively exploring and implementing CCU technologies to further reduce the carbon footprint of its operations.

The result? Eramet reports a significant reduction in CO2 emissions for eraLow alloys, often exceeding [Insert Percentage or Specific Number]% compared to traditional methods. This substantial reduction positions eraLow as a key contributor to a lower-carbon steel industry. Eramet's commitment to sustainability has also been recognized through various industry awards and certifications [mention specific awards/certifications if available].

Benefits of Using eraLow Manganese Alloys

Beyond its environmental benefits, eraLow offers several advantages in terms of steel quality, performance, and market appeal.

Superior Steel Quality and Performance

Steel produced using eraLow manganese alloys exhibits enhanced characteristics:

- Increased Strength: Improved mechanical properties lead to stronger and more durable steel products.

- Improved Weldability: Facilitates easier and more reliable welding processes.

- Better Formability: Allows for greater flexibility in shaping and forming steel components.

These improvements translate to cost savings and increased efficiency for steel manufacturers. The superior quality of steel produced using eraLow opens doors to new applications and improves performance in existing ones.

Meeting Growing Demand for Sustainable Steel

The market for low-carbon steel is rapidly expanding, driven by increasing environmental awareness and stringent regulations. eraLow directly addresses this growing demand:

- Supporting the Circular Economy: Eramet's commitment to responsible sourcing and resource efficiency aligns perfectly with the principles of the circular economy.

- Customer Case Studies: [Include specific examples of successful customer implementations of eraLow and the positive results achieved].

- Future Market Projections: Market forecasts predict significant growth in the demand for low-carbon manganese alloys in the coming years, creating substantial opportunities for manufacturers who adopt sustainable practices.

Eramet's Commitment to Sustainability Beyond eraLow

Eramet's dedication to sustainability extends beyond the eraLow product line. The company embraces a holistic approach to responsible mining and metallurgy.

A Holistic Approach to Sustainable Mining and Metallurgy

Eramet's commitment includes:

- Responsible Sourcing: Prioritizing ethical and environmentally responsible sourcing of raw materials.

- Waste Reduction: Implementing innovative techniques to minimize waste generation and maximize resource recovery.

- Renewable Energy Usage: Increasing the use of renewable energy sources across its operations.

Eramet has set ambitious sustainability goals and targets, actively collaborating with industry partners and stakeholders to promote sustainable practices throughout the value chain. [Mention specific partnerships or collaborations related to sustainability initiatives].

Conclusion

Eramet's eraLow represents a paradigm shift in sustainable steel production. These low-carbon manganese alloys offer significant environmental advantages without compromising on the quality or performance of the resulting steel. By reducing CO2 emissions, improving steel properties, and meeting the growing demand for sustainable materials, eraLow is paving the way for a greener future in the steel industry. Discover how Eramet's eraLow can help your business achieve its sustainability goals. Contact us today to learn more about our range of low-carbon manganese alloys and build a greener future with sustainable steel.

Featured Posts

-

Recruiting Expats How Canada Can Outmaneuver The Us In The Talent War

May 14, 2025

Recruiting Expats How Canada Can Outmaneuver The Us In The Talent War

May 14, 2025 -

Celine Dions Eurovision Status An Update Days Before The Final

May 14, 2025

Celine Dions Eurovision Status An Update Days Before The Final

May 14, 2025 -

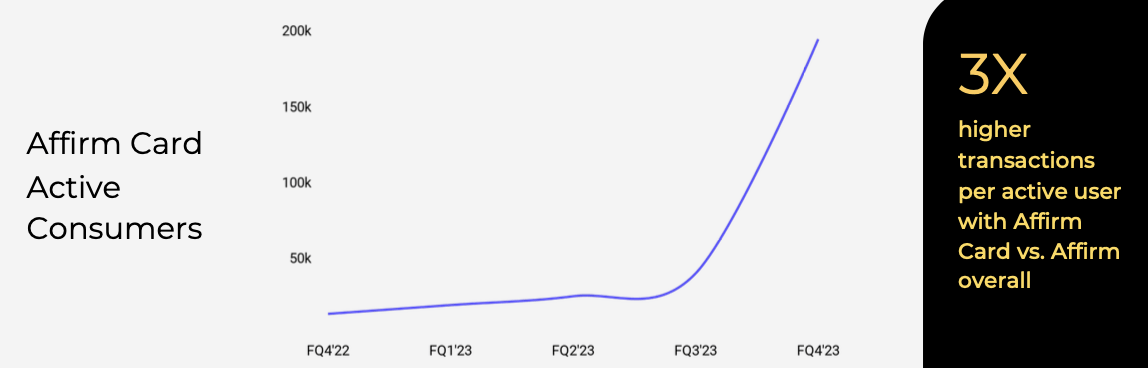

Trumps Trade War A Crushing Blow To Fintech Ipos Including Affirm Afrm

May 14, 2025

Trumps Trade War A Crushing Blow To Fintech Ipos Including Affirm Afrm

May 14, 2025 -

Lorraine Bracco And Brenda Vaccaros Nonna A Heartwarming Cinematic Experience

May 14, 2025

Lorraine Bracco And Brenda Vaccaros Nonna A Heartwarming Cinematic Experience

May 14, 2025 -

Are Banned Candles Being Sold On Etsy Walmart And Amazon In Canada

May 14, 2025

Are Banned Candles Being Sold On Etsy Walmart And Amazon In Canada

May 14, 2025

Latest Posts

-

Le Mans 24 Hours Federer Named Honorary Starter

May 14, 2025

Le Mans 24 Hours Federer Named Honorary Starter

May 14, 2025 -

Ro Er Federer Povratak I Zhelja Za Igrom Pred Publikom

May 14, 2025

Ro Er Federer Povratak I Zhelja Za Igrom Pred Publikom

May 14, 2025 -

Roger Federers Le Mans Honour A Historic First

May 14, 2025

Roger Federers Le Mans Honour A Historic First

May 14, 2025 -

Povratak Ro Era Federera Njegove Rechi O Publitsi I Punim Stadionima

May 14, 2025

Povratak Ro Era Federera Njegove Rechi O Publitsi I Punim Stadionima

May 14, 2025 -

Federer Potvr U E Povratak Dugo Ochekivani Povratak Na Terene

May 14, 2025

Federer Potvr U E Povratak Dugo Ochekivani Povratak Na Terene

May 14, 2025