Electric Motor Innovation: A Path To Global Supply Chain Diversification

Table of Contents

Technological Advancements Driving Diversification

Improved Motor Designs and Materials

Advancements in electric motor design and materials are pivotal to achieving supply chain diversification. The traditional reliance on rare-earth magnets in permanent magnet motors (PMMs) creates a significant vulnerability, as China currently dominates their production. However, innovations are underway to mitigate this risk:

- Switched Reluctance Motors (SRMs): These motors offer a rare-earth-free alternative, reducing reliance on specific geographic regions for critical materials. Their simpler design also simplifies manufacturing.

- Improved PMM designs: Research focuses on optimizing magnet usage and exploring alternative magnetic materials, such as ferrite magnets and nanocomposite magnets. This reduces the amount of rare-earth elements needed.

- High-temperature superconducting motors: These offer significantly higher efficiency and power density compared to conventional motors, potentially revolutionizing various applications.

[Insert links to relevant research papers or industry reports here, e.g., a report from the IEA or a relevant scientific publication.]

Advances in Manufacturing Processes

Modern manufacturing techniques are transforming electric motor production, enabling localization and enhancing resilience:

- Additive Manufacturing (3D Printing): 3D printing allows for the production of complex motor components on-demand, reducing transportation costs and lead times. It also enables localized production, even in remote areas.

- Automation and Robotics: Automated assembly lines significantly increase efficiency and reduce the need for large, centralized factories. This facilitates the establishment of smaller, distributed manufacturing facilities across different regions.

- Advanced machining techniques: Improved precision and efficiency in machining processes reduce waste and improve the quality of motor components, leading to longer lifespan and reduced maintenance costs.

These advancements reduce reliance on established manufacturing hubs, creating opportunities for regional economic growth and supply chain diversification.

Regional Production and Localization Strategies

Government Incentives and Policies

Governments worldwide recognize the strategic importance of electric motor manufacturing and are actively promoting domestic production through various incentives:

- Subsidies and tax breaks: Many countries offer financial support to companies investing in electric motor production facilities within their borders. Examples include [mention specific countries and their programs].

- Research and development funding: Government investment in research and development helps to accelerate innovation and drive the adoption of new technologies. This fosters a competitive landscape and boosts regional expertise.

- Trade policies: Strategic trade policies can be used to protect domestic industries and promote regional manufacturing capabilities.

These policies play a crucial role in shaping the global landscape of electric motor production and encouraging diversification.

Strategic Partnerships and Joint Ventures

Collaboration is key to successful regionalization:

- International partnerships: Companies are forging alliances to share knowledge, resources, and manufacturing capabilities. This reduces individual risk and accelerates technological advancement.

- Joint ventures: Joint ventures between companies from different regions foster technological exchange, promote capacity building, and enhance regional expertise.

Successful examples include [cite examples of successful collaborations in the electric motor industry]. These partnerships mitigate risks associated with single-source dependency and accelerate the development of a truly global and diversified supply chain.

The Role of Sustainability in Diversification

Environmentally Friendly Materials and Processes

Sustainability is intrinsically linked to supply chain resilience:

- Recycled materials: Utilizing recycled materials in motor manufacturing reduces the demand for raw materials, decreasing environmental impact and reliance on virgin resources.

- Sustainable manufacturing processes: Implementing energy-efficient manufacturing processes minimizes carbon footprint and operational costs. This promotes a more sustainable and responsible approach to production.

Adopting environmentally friendly practices not only benefits the planet but also enhances the long-term viability and resilience of the electric motor supply chain.

Circular Economy Models for Electric Motors

A circular economy approach extends the lifespan of electric motors and reduces waste:

- Remanufacturing and refurbishment: Extending the useful life of motors through remanufacturing and refurbishment reduces the demand for new components and minimizes waste.

- Efficient recycling and material recovery: Developing robust recycling processes enables the recovery of valuable materials, minimizing reliance on primary resources and reducing environmental impact.

By adopting these strategies, we can create a more sustainable and resilient electric motor supply chain, benefiting both the environment and the economy.

Conclusion

Electric motor innovation is not merely a technological pursuit; it is a critical element in securing a resilient and diversified global supply chain. Technological advancements in motor design and manufacturing processes, combined with strategic regional production strategies and a focus on sustainability, are paving the way for a more robust and equitable industry. The key takeaways are the importance of: reducing reliance on single-source suppliers, promoting regional manufacturing, embracing sustainable practices, and fostering international collaboration.

We urge companies, governments, and researchers to invest in and support electric motor innovation initiatives. By working together, we can build a future where the global supply chain for electric motors is not only resilient but also environmentally sustainable and economically beneficial for all. Let's accelerate the transition to a diversified and sustainable future through continued investment in electric motor innovation and related technologies.

Featured Posts

-

The Singapore Vote A Crucial Test For The Peoples Action Party

May 05, 2025

The Singapore Vote A Crucial Test For The Peoples Action Party

May 05, 2025 -

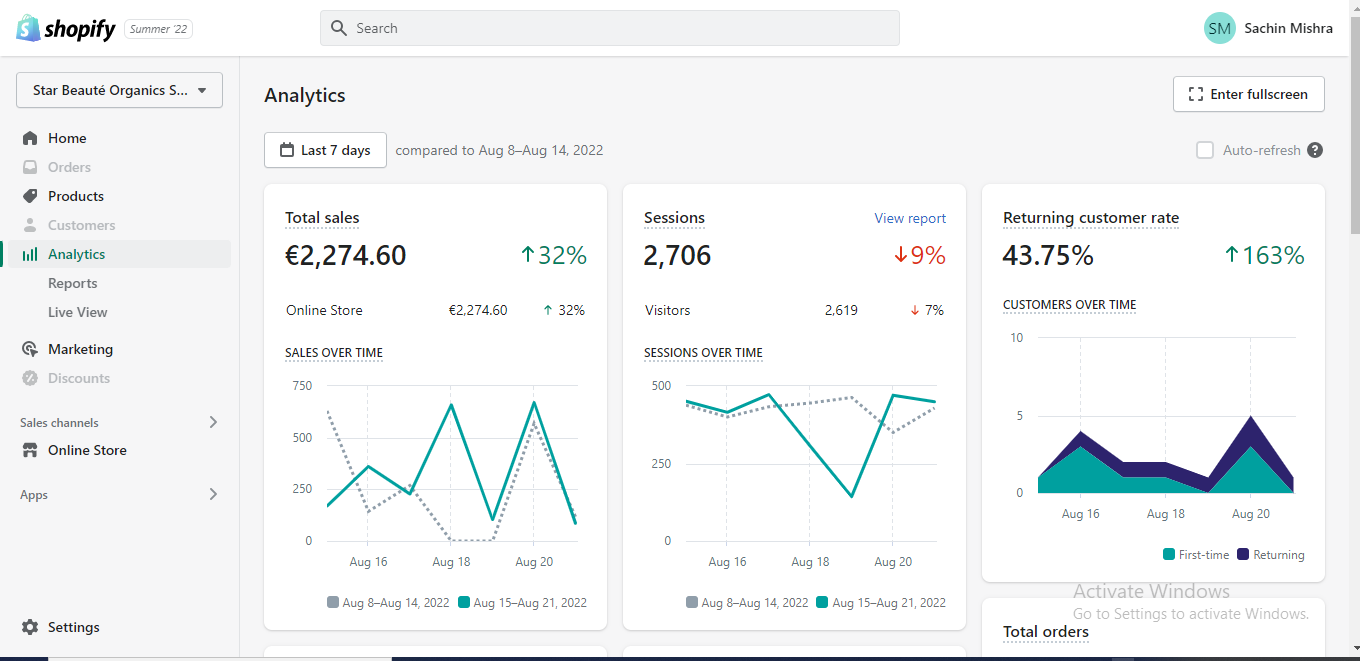

Understanding The Shift To A Lifetime Revenue Share For Shopify Developers

May 05, 2025

Understanding The Shift To A Lifetime Revenue Share For Shopify Developers

May 05, 2025 -

Lizzos Los Angeles Performance Showcasing A Defined Waist And Voluptuous Figure

May 05, 2025

Lizzos Los Angeles Performance Showcasing A Defined Waist And Voluptuous Figure

May 05, 2025 -

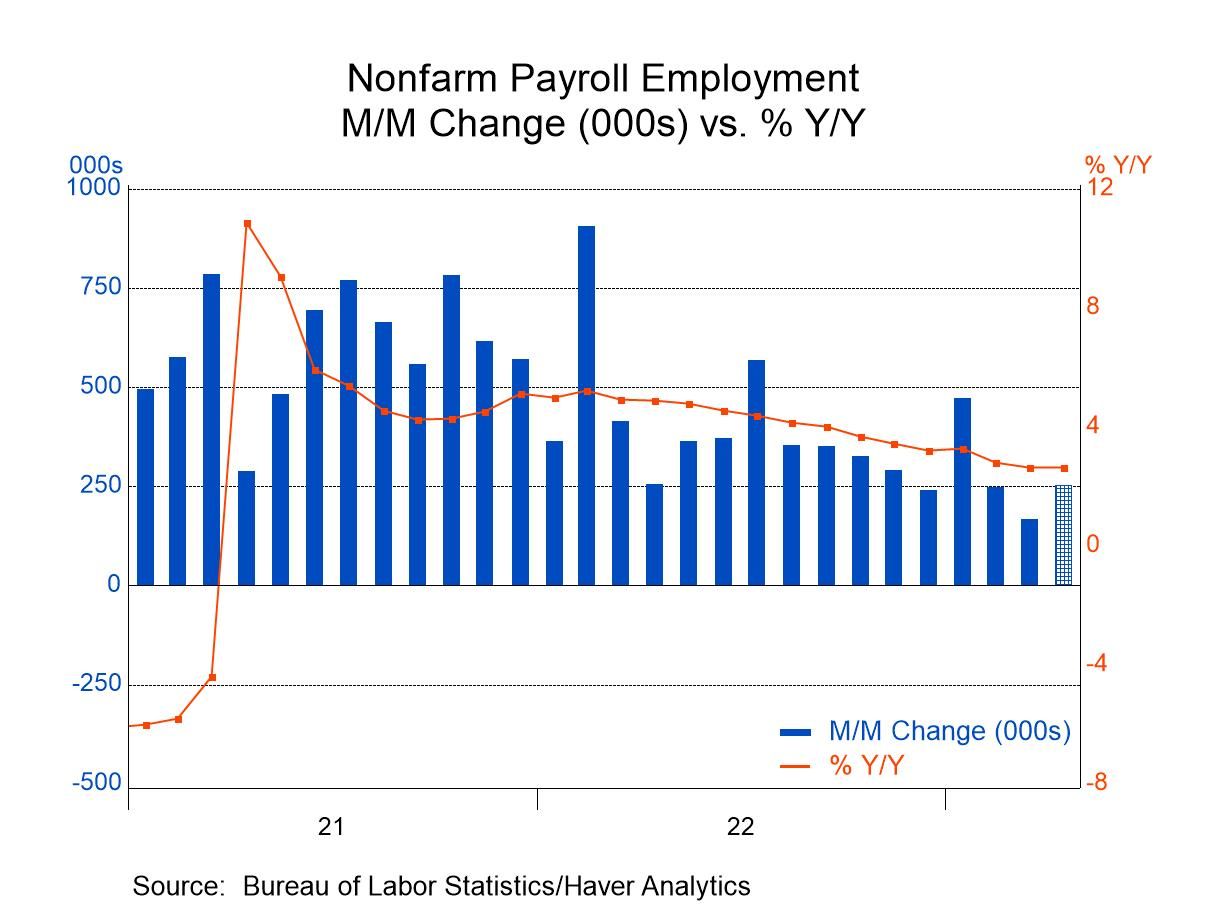

U S Economy Adds 177 000 Jobs In April Unemployment Rate Remains At 4 2

May 05, 2025

U S Economy Adds 177 000 Jobs In April Unemployment Rate Remains At 4 2

May 05, 2025 -

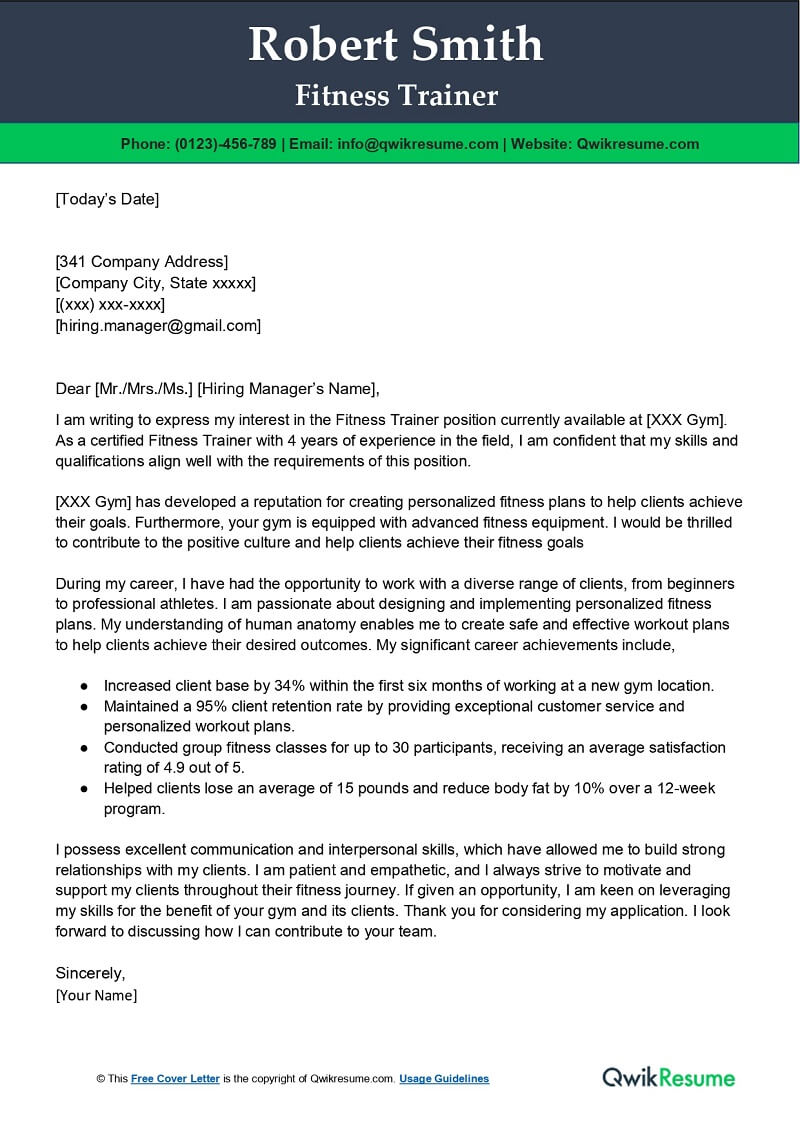

Lizzos Fitness Journey A Trainers Defense

May 05, 2025

Lizzos Fitness Journey A Trainers Defense

May 05, 2025

Latest Posts

-

Ufc 314 Ppv Updated Lineup After Prates And Neal Bout Cancelled

May 05, 2025

Ufc 314 Ppv Updated Lineup After Prates And Neal Bout Cancelled

May 05, 2025 -

Ufc 314 Ppv Card Changes Prates Vs Neal Fight Cancelled

May 05, 2025

Ufc 314 Ppv Card Changes Prates Vs Neal Fight Cancelled

May 05, 2025 -

Volkanovski Vs Lopes Ufc 314 A Comprehensive Review Of Winners And Losers

May 05, 2025

Volkanovski Vs Lopes Ufc 314 A Comprehensive Review Of Winners And Losers

May 05, 2025 -

Ufc 314 Fight Card Breakdown Volkanovski Vs Lopes Results And Analysis

May 05, 2025

Ufc 314 Fight Card Breakdown Volkanovski Vs Lopes Results And Analysis

May 05, 2025 -

Ufc 314 Winners Losers And Key Moments From Volkanovski Vs Lopes

May 05, 2025

Ufc 314 Winners Losers And Key Moments From Volkanovski Vs Lopes

May 05, 2025