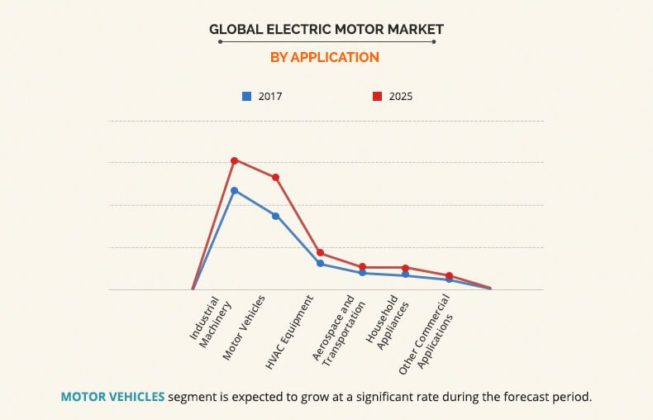

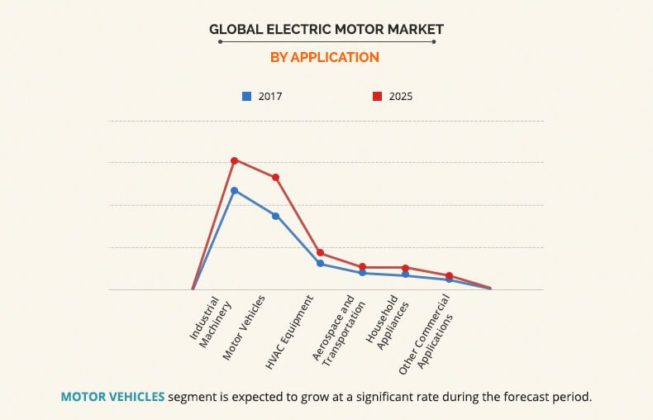

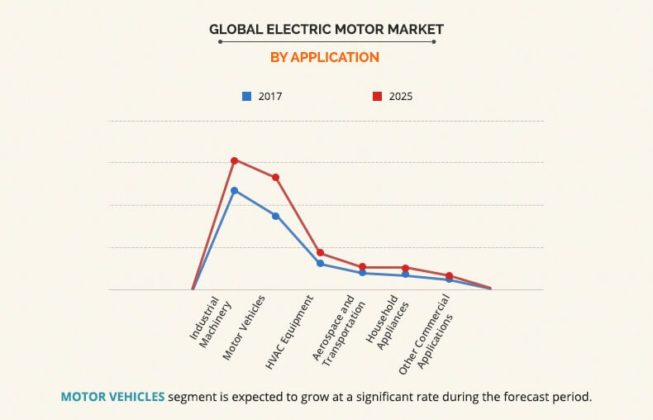

A Strategic Shift: Diversifying Global Electric Motor Production

Table of Contents

Geopolitical Risks and Supply Chain Vulnerabilities

The current landscape of electric motor manufacturing reveals a concerning over-reliance on specific geographical regions. This concentration creates significant vulnerabilities in the global supply chain. For example, the production of certain types of electric motors is heavily dependent on rare earth minerals sourced from a limited number of countries. This dependence exposes the industry to significant geopolitical risks.

- Increased vulnerability to geopolitical events: Trade wars, political instability, or even natural disasters in these key regions can severely disrupt production, leading to shortages and price spikes.

- Disruptions in raw material supply: Reliance on a single source for critical raw materials creates a bottleneck, making the entire supply chain vulnerable to disruptions.

- Transportation bottlenecks and delays: Concentrated production often leads to congested transportation routes, increasing the risk of delays and adding to overall costs.

- Price volatility due to supply constraints: The limited supply of key materials and components can lead to significant price fluctuations, impacting the profitability and competitiveness of manufacturers.

The keywords "supply chain resilience," "geopolitical risk," "electric motor manufacturing risk," and "raw material sourcing" are crucial for highlighting the vulnerability of the current system. Addressing these risks is paramount for securing the future of electric motor production.

The Economic Benefits of Diversification

Diversifying electric motor production across multiple regions offers significant economic advantages. By spreading the risk and tapping into diverse resources, manufacturers can enhance their resilience and profitability.

- Reduced production costs through economies of scale in multiple locations: Establishing manufacturing facilities in various regions can leverage local expertise and resources, leading to overall cost reductions.

- Access to cheaper labor and resources in different regions: Different regions offer varying labor costs and access to raw materials, allowing for optimized production costs.

- Enhanced market penetration and sales growth in diverse markets: Proximity to key markets reduces transportation costs and allows for quicker response to regional demand fluctuations. This enhances market penetration and fuels sales growth.

- Increased resilience to economic shocks: Diversification minimizes the impact of localized economic downturns or disruptions, enhancing the overall stability of the business.

The keywords "economic diversification," "global manufacturing strategy," "cost reduction strategies," and "market expansion" are essential for showcasing the economic advantages of a diversified approach.

Technological Advancements and Regional Specialization

Technological advancements are playing a pivotal role in enabling electric motor production in new locations. Automation and robotics are reducing the reliance on low-cost labor, making previously uneconomical regions viable for manufacturing.

- Automation and robotics allowing for efficient production in diverse locations: Advanced technologies allow for efficient production regardless of geographical location, opening up new possibilities for diversification.

- Development of more efficient and cost-effective manufacturing processes: Continuous innovation leads to more streamlined and cost-effective manufacturing processes, reducing production costs in all locations.

- Regional expertise in specific areas of electric motor technology (e.g., advanced materials, control systems): Leveraging regional expertise and specialized skills can enhance efficiency and innovation in electric motor production.

These factors, highlighted by the keywords "electric motor technology," "manufacturing automation," "regional competitiveness," and "innovation in electric motor production," are crucial for unlocking the potential of diverse manufacturing locations.

Strategies for Effective Diversification

Effectively diversifying global electric motor production requires a strategic approach. Businesses need to carefully consider various factors and implement appropriate strategies.

- Identifying suitable locations based on infrastructure, labor costs, and government support: A thorough assessment of potential locations is crucial to ensure the long-term success of diversification efforts.

- Establishing joint ventures or strategic partnerships with local companies: Collaborating with local partners can provide access to valuable knowledge, resources, and market insights.

- Investing in local manufacturing facilities and infrastructure: Investing in local facilities and infrastructure is essential for establishing a sustainable manufacturing presence in the chosen region.

- Utilizing government incentives and tax breaks: Many governments offer incentives to attract foreign investment in strategic industries, such as electric motor production.

The keywords "global sourcing strategy," "strategic partnerships," "foreign direct investment," and "government incentives" are essential when discussing effective diversification strategies.

Conclusion: Securing the Future of Electric Motor Production Through Diversification

Diversifying global electric motor production is not merely a strategic option; it is a strategic imperative. The benefits of a diversified approach—enhanced supply chain resilience, significant economic growth, and accelerated technological advancement—are undeniable. A shift away from centralized production towards a more distributed and resilient global supply chain is crucial for ensuring the long-term security and sustainability of the electric motor industry. We urge businesses and policymakers to actively adopt strategies for diversified electric motor manufacturing, ensuring a secure and sustainable future for this vital industry. Investing in a future-proof electric motor production system is an investment in the future of clean energy and sustainable industrial growth. Embrace the strategic diversification in electric motor production; it's the key to unlocking a more resilient and prosperous future.

Featured Posts

-

Father Daughter Duo Bradley Cooper And Lea At Super Bowl 2025

May 04, 2025

Father Daughter Duo Bradley Cooper And Lea At Super Bowl 2025

May 04, 2025 -

A Strategic Shift Diversifying Global Electric Motor Production

May 04, 2025

A Strategic Shift Diversifying Global Electric Motor Production

May 04, 2025 -

Google Faces U S Demand To Break Up Its Online Advertising Empire

May 04, 2025

Google Faces U S Demand To Break Up Its Online Advertising Empire

May 04, 2025 -

Backlash Against Lizzo For Remarks About Britney Spears And Janet Jackson

May 04, 2025

Backlash Against Lizzo For Remarks About Britney Spears And Janet Jackson

May 04, 2025 -

Nhl Playoffs First Round A Comprehensive Guide

May 04, 2025

Nhl Playoffs First Round A Comprehensive Guide

May 04, 2025