Why Automating Nike Sneaker Production Is So Difficult

Table of Contents

The Complexity of Sneaker Manufacturing

Sneaker production is a multifaceted process involving numerous intricate steps, from sourcing raw materials to the final quality checks. Automating this requires highly precise and adaptable robotic systems for each stage, a challenge that pushes current technological boundaries.

Sub-points:

-

Material Handling: Nike sneakers use diverse materials – leather, textiles, synthetics, rubber – in various shapes and thicknesses. Handling these materials reliably requires sophisticated robotic arms, advanced sensors, and grippers capable of adapting to different textures and weights. Inconsistencies in material properties further complicate automation.

-

Precise Assembly: The meticulous assembly of a sneaker involves stitching, gluing, and the precise placement of numerous components. This demands a level of dexterity and precision currently beyond the capabilities of most robots. The intricate patterns and varying tensions required for stitching, for example, are difficult to replicate reliably by automated systems.

-

Quality Control: Maintaining Nike's high standards requires rigorous quality control. Automated systems must be capable of identifying minute defects in materials and workmanship—a task that frequently relies on the keen eye and experience of human inspectors. Detecting subtle imperfections, such as inconsistencies in stitching or glue application, remains a significant challenge for automated quality control systems.

Bullet Points:

- High variability in materials and designs makes it difficult to create universal automation solutions.

- Current robotic technology lacks the dexterity and fine motor skills for some crucial assembly tasks.

- The human element remains vital for quality control and complex problem-solving.

Technological Limitations

Current robotic technology falls short of the dexterity and adaptability necessary for many sneaker-making processes. Significant advancements in AI and machine learning are crucial to bridging this gap.

Sub-points:

-

Dexterous Manipulation: Robots need far more agile "hands" and tools to handle delicate materials and perform intricate stitching, gluing, and other delicate assembly operations. Existing robotic grippers often lack the sensitivity and adaptability needed for such tasks.

-

Adaptive Programming: The software controlling these robots needs to adjust to variations in materials, designs, and even minor manufacturing inconsistencies without constant reprogramming by human engineers. This requires advanced AI algorithms capable of real-time adaptation and error correction.

-

Sensor Technology: Advanced sensors are essential for accurate material recognition, quality inspection, and precise movement control. High-resolution vision systems and tactile sensors capable of detecting subtle variations in material properties are critical for robust automation.

Bullet Points:

- Development of more advanced robotic grippers and manipulation systems is a critical area of ongoing research.

- Improved AI algorithms are needed for real-time adaptation, problem-solving, and self-correction.

- High-resolution vision and tactile sensor systems are necessary for precise quality control and material handling.

Economic Considerations

The high initial investment in advanced robotics and automation systems presents a substantial barrier to entry for Nike. A careful cost-benefit analysis is essential to justify the investment.

Sub-points:

-

High Upfront Costs: Implementing advanced automation demands considerable investment in cutting-edge robots, specialized software, integration services, and extensive employee training programs.

-

Return on Investment (ROI): Nike must meticulously evaluate the ROI of automation against the costs of human labor, potential efficiency gains, and the risks associated with technological obsolescence.

-

Maintenance and Upgrading: Automated systems require ongoing maintenance, regular updates, and periodic upgrades, adding significantly to the long-term operational costs. Downtime due to equipment failure can also disrupt production and incur further costs.

Bullet Points:

- The cost of specialized robots and AI systems currently remains prohibitively high for widespread adoption.

- Integrating automation into existing production lines can be extremely complex and expensive.

- The potential for job displacement and associated social and economic costs needs careful consideration.

Logistical Challenges

Integrating automation into Nike's global supply chain and its diverse manufacturing facilities presents significant logistical hurdles.

Sub-points:

-

Global Supply Chain Integration: Automating across numerous factories and regions requires standardized processes, consistent technologies, and efficient communication networks. Maintaining consistency across diverse manufacturing facilities is a major logistical challenge.

-

Factory Layout and Infrastructure: Existing factory layouts may not be suitable for automated production lines, requiring extensive and costly modifications to accommodate new robotic systems and automated material handling equipment.

-

Workforce Retraining: Implementing automation requires reskilling or retraining the existing workforce to manage, operate, maintain, and troubleshoot the new automated systems. This investment in human capital is vital for successful automation.

Bullet Points:

- Standardization of manufacturing processes is essential for successful automation across Nike's global network.

- Factory redesign and infrastructure upgrades can be extremely expensive and time-consuming.

- Investing in comprehensive training programs for employees is crucial for a smooth transition to automation.

Conclusion

Automating Nike sneaker production is a formidable challenge, encompassing technological limitations, significant economic considerations, and substantial logistical hurdles. While partial automation is already being implemented in certain areas, complete automation remains a long-term goal. The intricate nature of sneaker manufacturing, along with the need for further advancements in robotics, AI, and supply chain management, means that complete automation of Nike's production remains a distant prospect. Further research and development are critical for overcoming the complexities involved in automating Nike sneaker production and realizing the potential benefits of increased efficiency and reduced costs. To delve deeper into the nuances of this complex undertaking, further research into the specifics of automating Nike sneaker production is essential.

Featured Posts

-

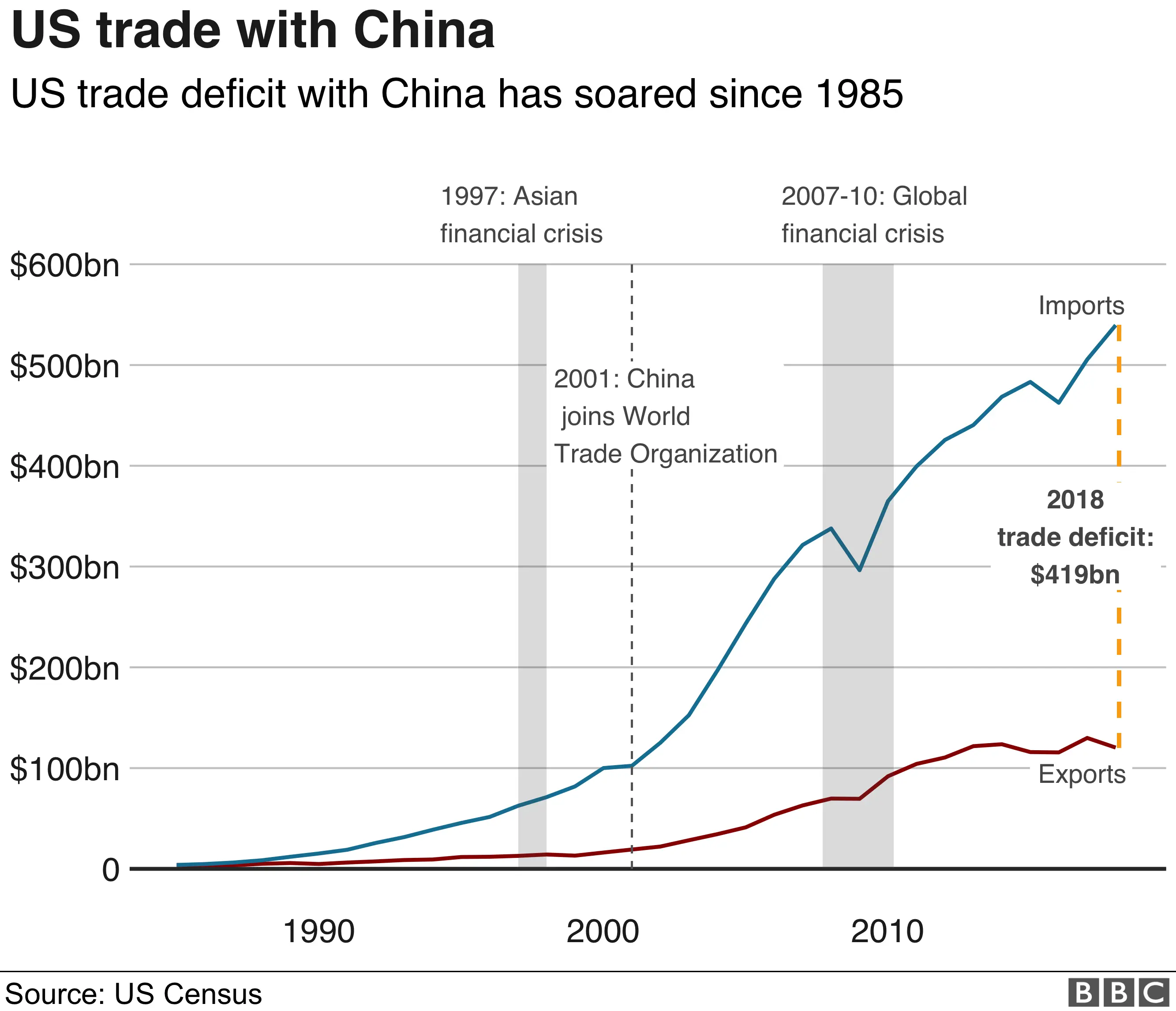

How Tariffs Threaten Chinas Export Led Growth Model

Apr 22, 2025

How Tariffs Threaten Chinas Export Led Growth Model

Apr 22, 2025 -

The Conclaves Challenge Continuing Pope Francis Work

Apr 22, 2025

The Conclaves Challenge Continuing Pope Francis Work

Apr 22, 2025 -

Kyivs Dilemma Responding To Trumps Plan To End The Ukraine Conflict

Apr 22, 2025

Kyivs Dilemma Responding To Trumps Plan To End The Ukraine Conflict

Apr 22, 2025 -

Alterya Joins Chainalysis Boosting Blockchain Security With Ai

Apr 22, 2025

Alterya Joins Chainalysis Boosting Blockchain Security With Ai

Apr 22, 2025 -

Another Round Doj And Google Clash Over Search Engine Dominance

Apr 22, 2025

Another Round Doj And Google Clash Over Search Engine Dominance

Apr 22, 2025