UPS And Figure AI: Humanoid Robot Deployment Partnership

Table of Contents

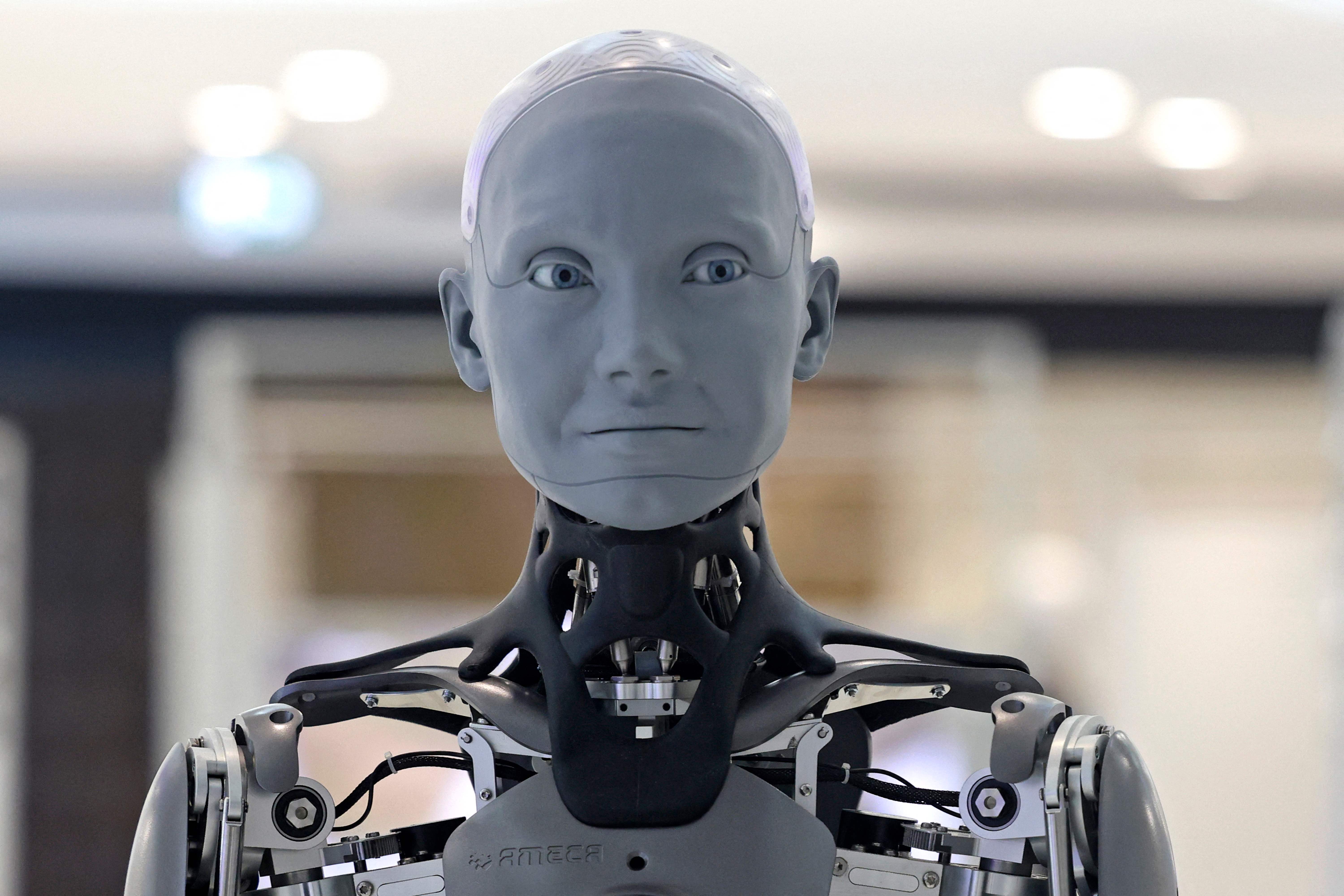

Figure AI's Humanoid Robots: Capabilities and Advantages

Figure AI's humanoid robots represent a significant leap forward in robotics technology. Their capabilities far surpass those of traditional automated systems, opening up new possibilities for warehouse automation and beyond.

Advanced Dexterity and Manipulation

Figure AI's robots possess an unparalleled level of dexterity and manipulation. Unlike their predecessors, these robots can perform complex tasks requiring fine motor skills, previously deemed impossible for automated systems.

- Picking and placing delicate items: Handling fragile goods with precision, minimizing damage.

- Sorting packages with precision: Accurately categorizing and routing packages based on destination and other criteria.

- Operating machinery: Interacting with and controlling existing warehouse equipment, increasing overall system efficiency.

- Interacting with existing warehouse infrastructure: Seamlessly integrating into current warehouse layouts and workflows.

This advanced dexterity is enabled by a combination of advanced sensors, AI-powered control systems, and sophisticated algorithms that allow for real-time adaptation and problem-solving. The robots can learn from their experiences, improving their performance over time.

Enhanced Efficiency and Productivity

The deployment of these robots translates directly into significant improvements in warehouse efficiency and productivity. Their ability to handle repetitive tasks with speed and accuracy minimizes human error and boosts throughput.

- Faster package handling: Increased speed in picking, packing, and sorting packages, leading to faster order fulfillment.

- Improved order accuracy: Reduced errors in order picking and packing, leading to higher customer satisfaction.

- Reduced labor costs: Automation of repetitive tasks frees up human workers to focus on higher-value activities.

- Increased throughput: Significant increases in the number of packages processed per hour, improving overall warehouse capacity.

For example, in a real-world scenario, a warehouse might see a 20% increase in packages processed per hour, a 15% reduction in order fulfillment times, and a 10% decrease in order errors – all thanks to the deployment of Figure AI's robots.

Adaptability and Scalability

Figure AI's robots are designed for adaptability and scalability. They can be easily integrated into existing warehouse environments and workflows, adapting to various layouts and operational requirements.

- Easy integration into existing workflows: Minimal disruption to existing processes during implementation.

- Ability to handle varying package sizes and weights: Adaptable to a wide range of products and order types.

- Potential for deployment in diverse warehouse configurations: Flexibility to adapt to different warehouse designs and layouts.

The modular design and flexible software architecture allow for easy scaling of operations. As business needs grow, more robots can be added seamlessly, providing a scalable solution for expanding warehouse capacity without significant infrastructural changes.

UPS's Strategic Implementation of Humanoid Robots

UPS's strategic implementation of Figure AI's humanoid robots is a response to several key challenges and opportunities within the logistics industry. This initiative highlights UPS's commitment to innovation and its forward-thinking approach to optimizing operations.

Addressing Labor Shortages

The logistics industry is facing a significant labor shortage, making it increasingly difficult to meet growing demands. Humanoid robot deployment offers a solution to this critical challenge.

- Filling critical labor gaps: Addressing immediate needs for warehouse personnel in high-demand areas.

- Improving employee retention: Reducing the strain on existing employees by automating repetitive tasks, allowing them to focus on more engaging and higher-skill work.

- Optimizing workforce allocation: Efficiently distributing human resources to areas requiring human oversight and intervention.

By augmenting the human workforce with robots, UPS can ensure operational continuity and meet customer demands even during periods of labor scarcity. The projected growth in e-commerce further emphasizes the need for automation to address these increasing demands.

Optimizing Warehouse Operations

UPS plans to integrate Figure AI's robots into its existing warehouse management systems (WMS) and workflows to maximize efficiency. This will involve a range of applications across various warehouse processes.

- Automated package sorting: Robots sorting packages based on various criteria (destination, size, weight, etc.) for optimal routing.

- Inventory management: Robots assisting in inventory tracking, reducing discrepancies and optimizing storage space.

- Order picking and packing: Robots picking, packing, and labeling orders with improved speed and accuracy.

- Improved warehouse safety: Robots handling hazardous materials and reducing the risk of workplace injuries to human workers.

This integration will involve sophisticated software integration and careful planning to minimize disruption and maximize the benefits of automation. The anticipated impact on operational costs will be significant, offering both short-term and long-term advantages.

Exploring Last-Mile Delivery Applications

The potential applications extend beyond warehouse operations. UPS is also exploring the use of humanoid robots in last-mile delivery, an area currently facing significant challenges.

- Autonomous delivery of smaller packages: Robots delivering packages directly to customers in specific geographic areas.

- Potential for reduced delivery times: Optimizing delivery routes and reducing transit times for certain types of deliveries.

- Expansion into new delivery markets: Enabling delivery services in areas with limited infrastructure or labor availability.

This represents a significant frontier, however, there are technological and regulatory hurdles to overcome. Challenges include ensuring safe and secure navigation in complex environments, addressing regulatory compliance, and ensuring public acceptance of autonomous delivery robots.

The Future of Logistics: Human-Robot Collaboration

The partnership between UPS and Figure AI is a strong indicator of the broader trends shaping the future of the logistics industry. The integration of AI and robotics is not simply a technological advancement but a fundamental shift in how logistics operations are managed.

The Role of AI in Logistics Automation

Artificial intelligence plays a crucial role in enabling advanced robotics in logistics. AI algorithms are essential for tasks such as path planning, object recognition, and decision-making within complex warehouse environments.

- Increased automation: AI-driven robots performing a wider range of tasks, increasing automation levels throughout the supply chain.

- Improved supply chain visibility: AI-powered data analytics providing better insights into inventory levels, order status, and delivery times.

- Enhanced customer experience: Faster and more reliable delivery services, resulting in improved customer satisfaction.

- Data-driven decision-making: Leveraging data analysis to optimize logistics processes, reduce costs, and improve efficiency.

The wider adoption of AI-powered solutions will have profound impacts on employment, requiring a shift towards higher-skill roles that focus on managing and maintaining these advanced systems. It also offers significant potential for environmental improvements through optimization and reduced fuel consumption.

The Synergistic Partnership between UPS and Figure AI

The partnership between UPS and Figure AI is a powerful example of synergy in action. Both organizations stand to gain significant benefits from this collaboration.

- Shared innovation: Combining UPS's logistical expertise with Figure AI's robotics technology to drive innovation in the industry.

- Market leadership: Establishing a leading position in the field of humanoid robot deployment in logistics.

- Technological advancements: Accelerating the development and refinement of humanoid robot technology for logistics applications.

- Positive brand image: Demonstrating a commitment to innovation and technological advancement.

This partnership is likely to serve as a model for future collaborations between established logistics companies and cutting-edge robotics firms, driving further innovation and technological advancements within the sector.

Conclusion

The partnership between UPS and Figure AI represents a pivotal moment in the deployment of humanoid robots within the logistics industry. By leveraging the advanced capabilities of Figure AI's robots, UPS is poised to revolutionize its operations, enhance efficiency, address labor challenges, and ultimately transform the customer experience. This collaboration showcases the immense potential of human-robot collaboration to drive innovation and optimize complex logistical processes. Stay updated on the latest developments in humanoid robot deployment and its impact on the future of logistics. Witness the future of logistics unfold, and embrace the opportunities offered by this transformative technology.

Featured Posts

-

Your March Roster Roundup Dancers And Directors On The Move

Apr 30, 2025

Your March Roster Roundup Dancers And Directors On The Move

Apr 30, 2025 -

The Cruise Packing List What To Exclude

Apr 30, 2025

The Cruise Packing List What To Exclude

Apr 30, 2025 -

The X Files Future Anderson And Carter Discuss A Ryan Coogler Project

Apr 30, 2025

The X Files Future Anderson And Carter Discuss A Ryan Coogler Project

Apr 30, 2025 -

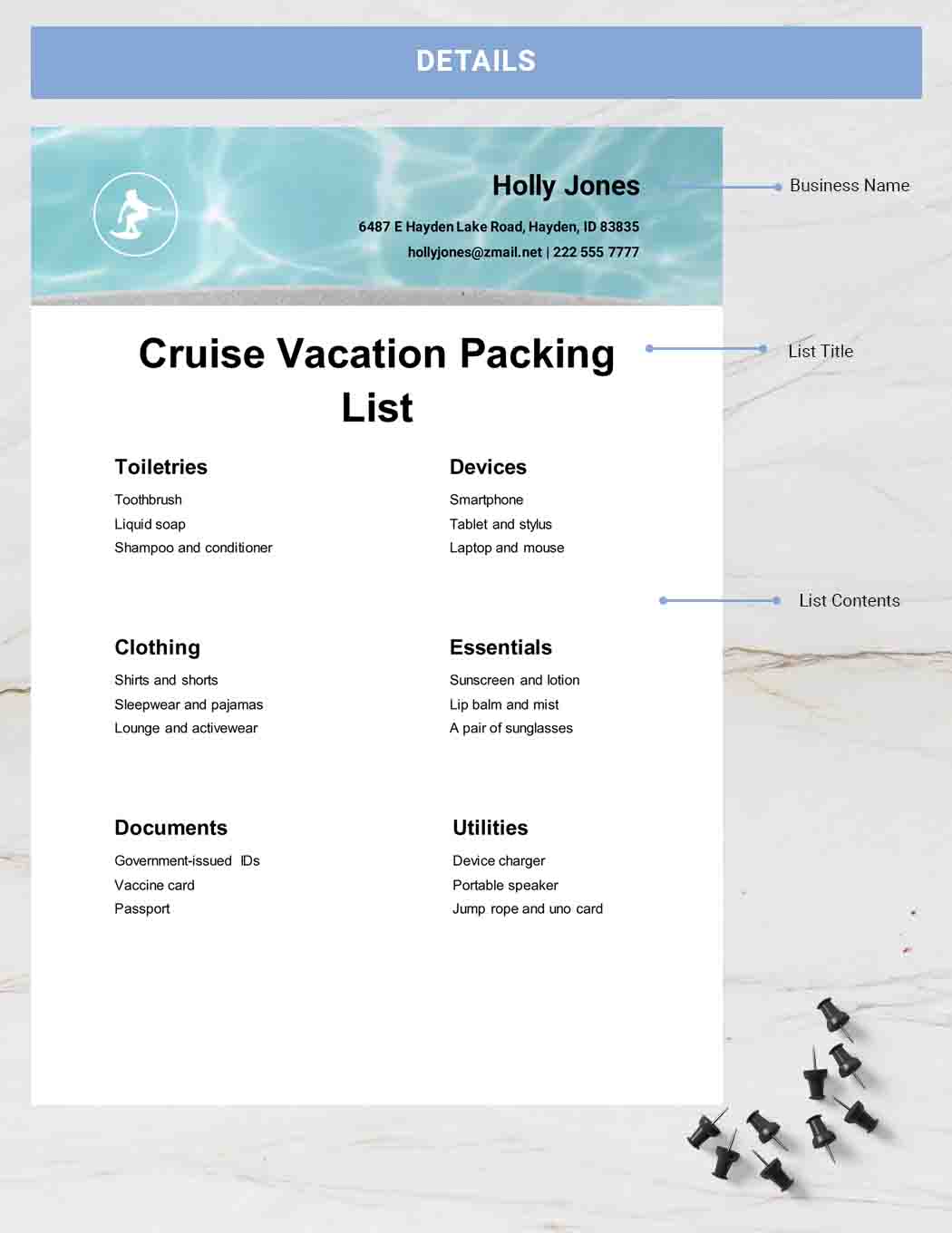

Auto Industry Conflict Dealers Resist Ev Sales Requirements

Apr 30, 2025

Auto Industry Conflict Dealers Resist Ev Sales Requirements

Apr 30, 2025 -

Thunder Over Louisville Fireworks Canceled Ohio River Flooding

Apr 30, 2025

Thunder Over Louisville Fireworks Canceled Ohio River Flooding

Apr 30, 2025