Understanding Big Rig ROCK Report 3.12 & Laser 101.7

Table of Contents

Big Rig ROCK Report 3.12: A Deep Dive

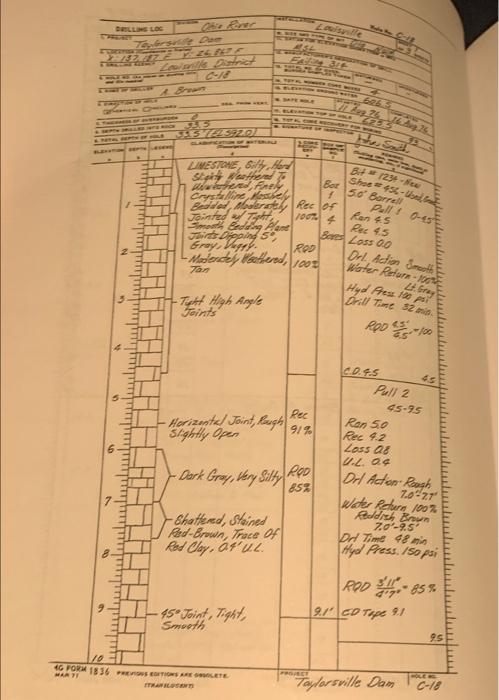

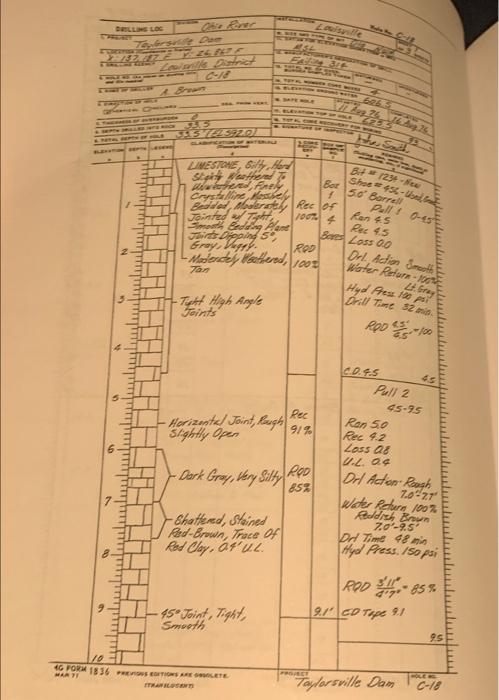

What is the ROCK Report 3.12?

The ROCK Report 3.12 is a crucial diagnostic tool used in the maintenance and inspection of big rigs and other heavy vehicles. Its significance lies in its ability to provide a detailed overview of the vehicle's systems, allowing for proactive maintenance and the prevention of costly breakdowns. By providing real-time data on various critical components, the ROCK Report 3.12 plays a key role in ensuring operational efficiency and enhancing overall vehicle safety. This report includes data points like brake system diagnostics, tire pressure readings, and engine performance indicators.

- Key Features and Benefits:

- Improved preventative maintenance scheduling, minimizing downtime.

- Reduced downtime due to unexpected failures, saving time and money.

- Enhanced safety for drivers and the public by identifying potential mechanical issues.

- Streamlined reporting for easy compliance with DOT regulations and internal safety audits.

Interpreting ROCK Report 3.12 Data

Effectively interpreting the data within the ROCK Report 3.12 is paramount. This involves understanding the various metrics presented and recognizing potential problems indicated by specific values or error codes.

A step-by-step approach to interpreting the report should involve:

- Reviewing all sections: Start with a comprehensive overview of all data points.

- Focusing on critical alerts: Pay close attention to any warnings or error codes flagged by the system.

- Cross-referencing data: Compare data points from different sections to identify patterns or related issues.

- Consulting documentation: If unsure about a specific error code or data point, refer to the official ROCK Report 3.12 documentation.

- Critical Data Points to Monitor:

- Engine performance indicators: Look for deviations in fuel consumption, oil pressure, and engine temperature.

- Transmission and drivetrain diagnostics: Monitor gear shifting performance and detect any unusual vibrations or noises.

- Brake system status and wear indicators: Check brake pad thickness, ABS functionality, and brake fluid levels.

- Suspension and steering system health: Identify signs of wear and tear, alignment issues, and potential instability.

Laser 101.7: Precise Measurement for Vehicle Inspections

Understanding Laser Technology in Vehicle Inspections

Laser 101.7 utilizes advanced laser measurement technology to provide highly accurate and efficient data collection during big rig inspections. Compared to traditional manual measurement methods, laser technology offers significantly improved accuracy, reducing human error and ensuring compliance with stringent safety standards. This technology streamlines the inspection process, saving valuable time and resources.

- Advantages of Laser Measurement:

- Increased speed and efficiency of inspections.

- Improved accuracy in measuring key parameters such as wheel alignment and tire tread depth.

- Reduced reliance on manual measurements, minimizing human error.

- Objective data collection for comprehensive and verifiable reports.

Applications of Laser 101.7 in Big Rig Maintenance

Laser 101.7 finds applications across various aspects of big rig maintenance, from pre-trip inspections to post-accident damage assessments. Its precision ensures that maintenance is performed correctly and efficiently.

- Practical Applications:

- Pre-trip inspections: Quickly and accurately assess critical parameters like tire pressure, wheel alignment, and overall vehicle dimensions before commencing a journey.

- Post-accident damage assessments: Provide precise measurements of damage for accurate repair estimates and insurance claims.

- Regular maintenance checks: Ensure optimal vehicle performance through timely identification and correction of alignment and dimensional issues.

- Compliance audits: Provide objective data for regulatory bodies to verify compliance with safety standards and DOT regulations.

Conclusion

Mastering the use of the Big Rig ROCK Report 3.12 and Laser 101.7 is crucial for maintaining a safe and compliant fleet. By understanding the data provided by the ROCK Report and utilizing the precision of Laser 101.7, you can significantly improve vehicle maintenance, reduce downtime, and enhance overall operational efficiency. This leads to cost savings, increased safety, and improved compliance with DOT regulations. Don't wait for problems to arise – proactively utilize the Big Rig ROCK Report 3.12 and Laser 101.7 to ensure your heavy vehicles are operating at peak performance and safety. Learn more about optimizing your Big Rig inspections and improving your heavy vehicle safety today!

Featured Posts

-

X101 5 Big Rig Rock Report 3 12 Full Report Breakdown

May 23, 2025

X101 5 Big Rig Rock Report 3 12 Full Report Breakdown

May 23, 2025 -

October 2023 Movies Leaving Hulu Streaming Service

May 23, 2025

October 2023 Movies Leaving Hulu Streaming Service

May 23, 2025 -

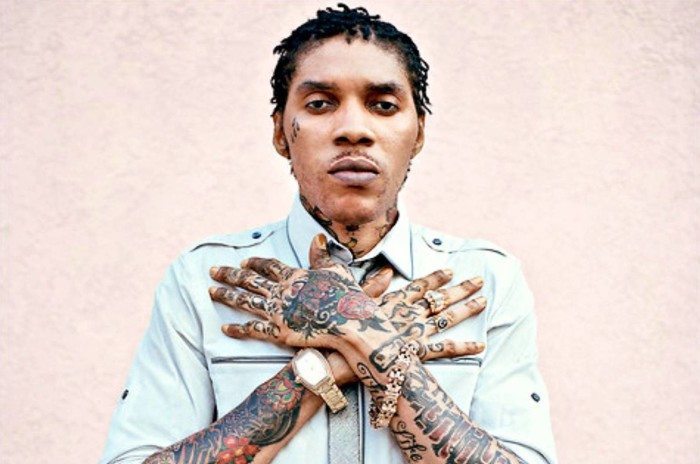

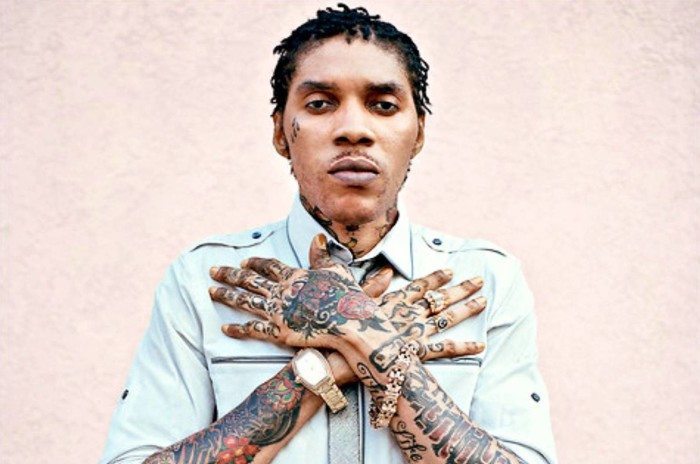

Vybz Kartel Sends Support As Dancehall Stars Trinidad Concert Faces Restrictions

May 23, 2025

Vybz Kartel Sends Support As Dancehall Stars Trinidad Concert Faces Restrictions

May 23, 2025 -

The Big Rig Rock Report 3 12 97 1 Double Q Practical Applications

May 23, 2025

The Big Rig Rock Report 3 12 97 1 Double Q Practical Applications

May 23, 2025 -

Wolffs Optimism A Strong F1 Season Start

May 23, 2025

Wolffs Optimism A Strong F1 Season Start

May 23, 2025

Latest Posts

-

Vybz Kartel Sends Support As Dancehall Stars Trinidad Concert Faces Restrictions

May 23, 2025

Vybz Kartel Sends Support As Dancehall Stars Trinidad Concert Faces Restrictions

May 23, 2025 -

Your Guide To Weekend Events Fashion Heritage Ballet And Puns

May 23, 2025

Your Guide To Weekend Events Fashion Heritage Ballet And Puns

May 23, 2025 -

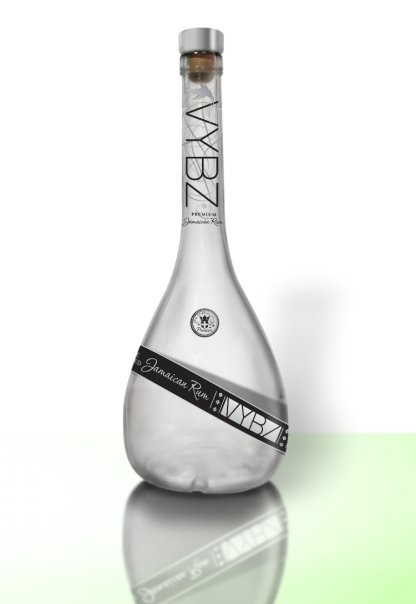

Kartel And Rum Culture In Stabroek News A Deep Dive

May 23, 2025

Kartel And Rum Culture In Stabroek News A Deep Dive

May 23, 2025 -

Ballet Fashion And Heritage A Weekend Of Events

May 23, 2025

Ballet Fashion And Heritage A Weekend Of Events

May 23, 2025 -

Weekend Events Fashion Heritage Ballet And Puns

May 23, 2025

Weekend Events Fashion Heritage Ballet And Puns

May 23, 2025