U.S. Electric Motor Production: A Path To Global Supply Chain Diversification

Table of Contents

The Current State of U.S. Electric Motor Manufacturing

The U.S. currently holds a comparatively small share of the global electric motor market, facing stiff competition from established players in Asia and Europe. While the U.S. possesses a strong foundation in advanced engineering and manufacturing, challenges remain.

-

Key Challenges:

- High labor costs: Competing with lower labor costs in other countries requires strategic investment in automation and efficiency.

- Skilled workforce shortage: A lack of skilled technicians and engineers hinders the expansion of domestic production. Addressing this requires robust training initiatives.

- Regulatory hurdles: Navigating complex regulations and permitting processes can slow down production and increase costs.

-

Opportunities for Growth:

- Government incentives: Federal and state government programs offer significant opportunities for investment in U.S. electric motor manufacturing.

- Technological advancements: Innovations in electric motor design and manufacturing processes create opportunities to produce high-efficiency, cost-effective motors.

- Reshoring initiatives: Companies are increasingly looking to bring manufacturing back to the U.S., driven by concerns about supply chain reliability and geopolitical stability.

Examples of U.S. electric motor manufacturers include companies specializing in specific motor types (e.g., industrial motors, automotive motors), each playing a role in the overall market landscape. Their success stories demonstrate the potential for growth with the right support.

Government Policies and Incentives Driving Domestic Production

Government policies play a pivotal role in shaping the landscape of U.S. electric motor production. Various initiatives aim to incentivize domestic manufacturing and foster innovation.

-

Specific Government Programs:

- The Bipartisan Infrastructure Law includes significant investments in electric vehicle charging infrastructure, indirectly boosting demand for electric motors.

- Clean energy initiatives, such as tax credits for renewable energy projects, stimulate the demand for motors used in wind turbines and solar power systems.

- Funding for research and development in advanced manufacturing technologies directly supports the improvement of electric motor production processes.

-

Impact and Effectiveness: These policies have begun to attract significant investment in U.S. electric motor manufacturing, creating jobs and fostering innovation. However, ongoing evaluation and adjustments are crucial to ensure their continued effectiveness and address any unforeseen challenges. Streamlining regulations and providing more targeted incentives could further enhance their impact.

Technological Advancements and Innovation in U.S. Electric Motor Technology

The U.S. has a rich history of innovation in electrical engineering, and this legacy continues to fuel advancements in electric motor technology.

-

Key Technological Advancements:

- High-efficiency motors: Improvements in motor design and materials are leading to significantly more energy-efficient motors, reducing operating costs and environmental impact.

- Permanent magnet motors: These motors offer high torque density and efficiency, making them ideal for electric vehicles and industrial applications.

- Advanced control systems: Sophisticated control systems optimize motor performance, leading to improved efficiency and extended lifespan.

-

Key Players: Leading universities, national labs (such as the National Renewable Energy Laboratory), and private companies are driving innovation in electric motor technology, ensuring the U.S. remains at the forefront of this critical sector. This collaborative research environment is a key strength.

Building a Skilled Workforce for U.S. Electric Motor Manufacturing

A robust and skilled workforce is paramount to the success of increased U.S. electric motor production. Addressing the skills gap requires a multifaceted approach.

-

Skills Gaps and Training: The industry needs skilled technicians, engineers, and manufacturing specialists proficient in advanced technologies like robotics, automation, and data analytics. Specialized training programs and apprenticeships are essential to bridge these gaps.

-

Industry-Education Collaboration: Partnerships between educational institutions and industry players are crucial for developing relevant curricula and providing practical training opportunities for students. This ensures graduates possess the skills demanded by employers.

-

Successful Initiatives: Several programs already exist, focusing on apprenticeships, vocational training, and university-level engineering programs tailored to the electric motor industry. Their success needs to be replicated and scaled up to meet the growing demand.

The Economic and Geopolitical Benefits of Diversified Electric Motor Supply Chains

Diversifying the electric motor supply chain offers significant economic and geopolitical advantages for the U.S.

-

Economic Benefits: Increased domestic production translates to job creation, economic growth, reduced reliance on imports, and a decrease in trade deficits. Investing in this sector will stimulate related industries, creating a ripple effect throughout the economy.

-

National Security Implications: Reducing dependence on foreign suppliers of critical components is crucial for national security, protecting the U.S. from potential supply chain disruptions caused by geopolitical instability or natural disasters. This self-reliance strengthens overall national resilience.

-

Global Competitiveness: Investing in and advancing U.S. electric motor production enhances the U.S.'s global competitiveness, solidifying its position as a leader in advanced manufacturing and clean energy technologies.

Conclusion: Securing the Future of U.S. Electric Motor Production

Increasing U.S. electric motor production is not just about manufacturing; it's about securing America's economic future, strengthening national security, and building a more resilient supply chain. Government policies, technological innovation, and a highly skilled workforce are essential elements in achieving this goal. Investing in U.S. electric motor manufacturing is an investment in America's future. We urge readers to learn more about the opportunities and challenges in this sector and support policies that promote domestic production and supply chain diversification. The future of U.S. electric motor manufacturing depends on our collective efforts to foster growth and innovation within this critical industry.

Featured Posts

-

Nigel Farages Whats App Messages A Crisis Of Integrity In The Reform Party

May 04, 2025

Nigel Farages Whats App Messages A Crisis Of Integrity In The Reform Party

May 04, 2025 -

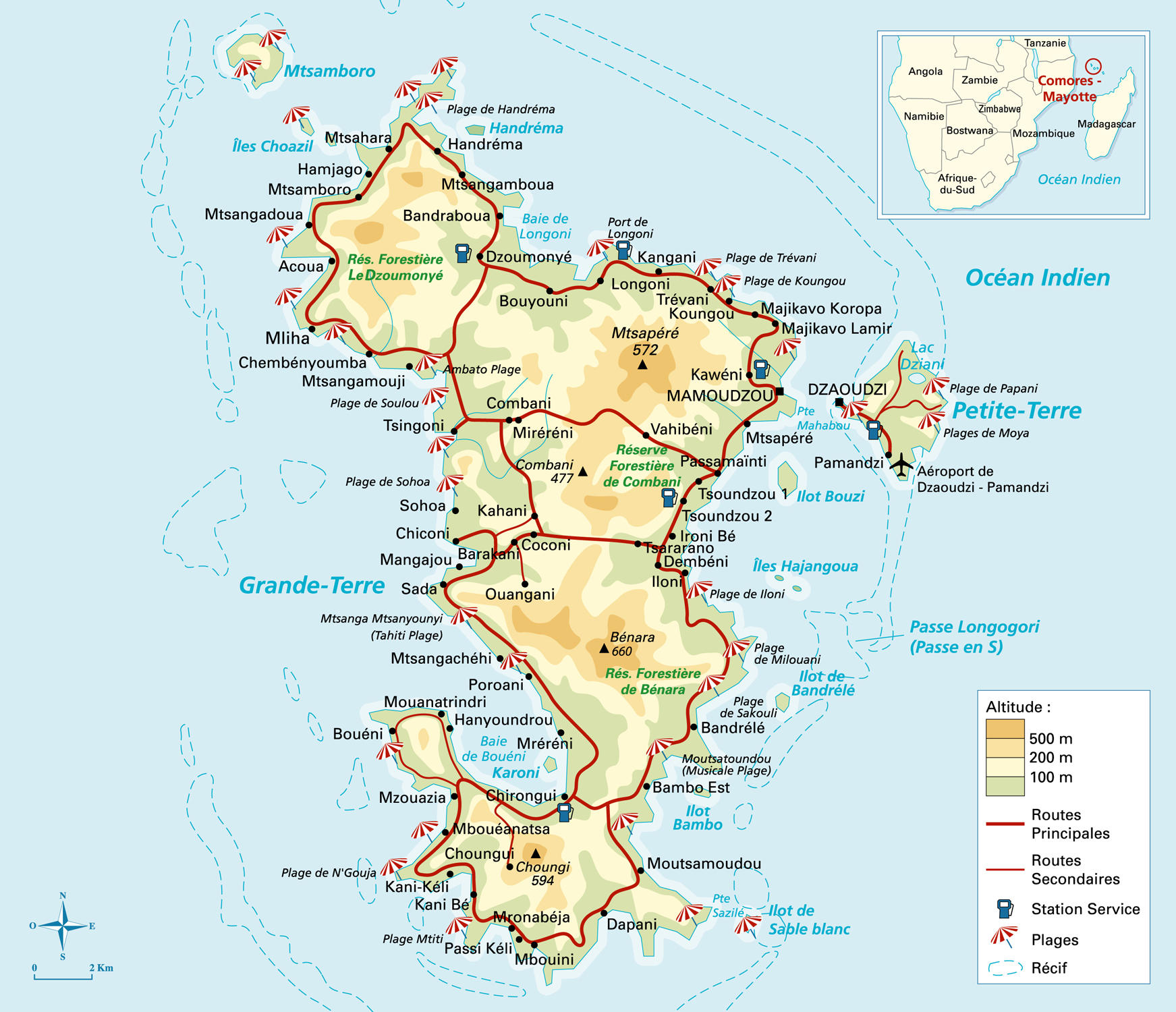

Mayotte Plus Francaise Que Nice Mais Toujours Colonisee

May 04, 2025

Mayotte Plus Francaise Que Nice Mais Toujours Colonisee

May 04, 2025 -

Ufc 314 Fight Card Volkanovski Vs Lopes And Undercard Predictions

May 04, 2025

Ufc 314 Fight Card Volkanovski Vs Lopes And Undercard Predictions

May 04, 2025 -

Max Verstappen And Partner Welcome First Child Babys Name Revealed

May 04, 2025

Max Verstappen And Partner Welcome First Child Babys Name Revealed

May 04, 2025 -

Sydney Sweeney Dazzles In Pink At Vanity Fairs Oscars After Party

May 04, 2025

Sydney Sweeney Dazzles In Pink At Vanity Fairs Oscars After Party

May 04, 2025