Trump Tariff Impact: Navigating The Challenges For Automakers

Table of Contents

Increased Production Costs and Prices

The tariffs directly increased the cost of steel and aluminum, fundamental components in vehicle manufacturing. This had a cascading effect throughout the industry.

Rising Raw Material Costs

- Increased material costs directly translate to higher vehicle prices. Automakers faced the difficult choice of absorbing these increased costs, impacting profitability, or passing them on to consumers, potentially dampening demand.

- Reduced competitiveness against foreign automakers who don't face the same tariffs. This created an uneven playing field, putting domestic automakers at a disadvantage in the global market.

- Pressure on automakers to absorb costs or pass them onto consumers, impacting sales. This delicate balancing act significantly impacted sales figures and overall market share.

- Strategies for cost mitigation (e.g., sourcing alternative materials, process optimization). Automakers had to become more creative and resourceful, exploring alternative materials and implementing process optimizations to reduce overall production costs. This involved significant investments in research and development.

Impact on Parts and Components

The impact extended beyond raw materials. Tariffs also affected imported parts and components, further escalating production costs.

- Disruption of established supply chains. Long-standing relationships with international suppliers were disrupted, requiring automakers to scramble for alternative solutions.

- Reliance on domestic suppliers, potentially leading to quality concerns or capacity limitations. Shifting to domestic suppliers presented new challenges, potentially impacting quality control and production capacity.

- Exploration of alternative sourcing strategies, increasing complexity and cost. Finding suitable replacements and renegotiating contracts added layers of complexity and increased expenses.

- Potential for delays in vehicle production due to supply chain disruptions. The instability in the supply chain inevitably led to production delays, further impacting profitability and customer satisfaction.

Supply Chain Disruptions and Restructuring

The tariffs forced automakers to fundamentally reassess their global supply chains. This restructuring proved to be a costly and complex undertaking.

Shifting Global Sourcing Strategies

Automakers had to adopt new strategies to minimize the effects of the tariffs.

- Increased reliance on domestic or tariff-free suppliers. This often meant renegotiating contracts and forging new partnerships, adding significant time and resource costs.

- Negotiation of new contracts with suppliers to offset tariff costs. Negotiations were intense, requiring careful balancing of costs, quality, and delivery times.

- Investments in new facilities and infrastructure to support reshoring initiatives. Some automakers invested heavily in reshoring initiatives, building new facilities and infrastructure within their domestic markets.

- Increased complexity and cost associated with managing a more diversified supply chain. The shift to a more diversified supply chain added complexity and cost, requiring sophisticated management systems and expertise.

Negotiating with Suppliers and Governments

Automakers engaged in complex negotiations with both suppliers and governments to minimize the negative impacts.

- Lobbying efforts to influence trade policy. Industry associations and individual automakers engaged in significant lobbying efforts to influence trade policy and seek relief from tariffs.

- Collaboration with suppliers to share the burden of tariff increases. Collaboration with suppliers was essential in finding ways to share the financial burden of tariff increases.

- Exploration of alternative manufacturing locations. Some automakers explored alternative manufacturing locations in countries with more favorable trade agreements.

- Pressure on governments for assistance and support. Automakers also sought assistance and support from their respective governments, aiming to mitigate the negative economic impact.

Consumer Impact and Market Share

The consequences of the tariffs weren't confined to the production floor; consumers also felt the impact.

Increased Vehicle Prices

The increased production costs were largely passed on to consumers, resulting in higher vehicle prices.

- Reduced consumer purchasing power. Higher prices reduced consumer purchasing power, impacting overall vehicle sales.

- Impact on sales volume and market share. The combination of higher prices and reduced consumer confidence led to lower sales volumes and shifts in market share.

- Shift in consumer preferences towards smaller or less expensive vehicles. Consumers responded to higher prices by shifting their preferences towards smaller, more fuel-efficient vehicles.

- Potential for market consolidation. The challenging economic climate may have led to market consolidation, with smaller players struggling to compete.

Impact on Competition

The tariffs created an uneven playing field, impacting global competition within the automotive industry.

- Advantages for domestic automakers producing in tariff-free zones or countries. Domestic automakers benefited from the tariffs, gaining a competitive advantage over their international counterparts.

- Disadvantages for foreign automakers importing vehicles or parts. Foreign automakers faced increased costs and reduced competitiveness, impacting their market share.

- Market share shifts and potential for increased domestic market dominance. The tariffs accelerated shifts in market share, potentially leading to increased dominance of domestic automakers.

- Long-term consequences for global competition and economic cooperation. The lasting consequences of these tariffs continue to impact global competition and international economic cooperation.

Conclusion

The Trump tariffs had a profound and multifaceted impact on the automotive industry. Automakers faced significant challenges related to increased production costs, supply chain disruptions, and changes in consumer demand. Successfully navigating this complex landscape required strategic adjustments to sourcing, manufacturing, and pricing strategies. Understanding the lasting effects of these tariffs remains crucial for automakers planning their future operations. To gain a deeper understanding of how to manage the ongoing effects of trade policies and their implications for your business, continue researching the long-term consequences of the Trump tariff impact. Develop comprehensive strategies to mitigate future economic uncertainty and ensure the resilience of your supply chain. Proactive planning and diversification are key to navigating the complexities of international trade and minimizing the negative impacts of future tariff changes.

Featured Posts

-

Farages Reform Uk Internal Divisions And The Threat Of A New Political Party

May 03, 2025

Farages Reform Uk Internal Divisions And The Threat Of A New Political Party

May 03, 2025 -

Netherlands Largest Heat Pump Utrecht Wastewater Plant Innovation

May 03, 2025

Netherlands Largest Heat Pump Utrecht Wastewater Plant Innovation

May 03, 2025 -

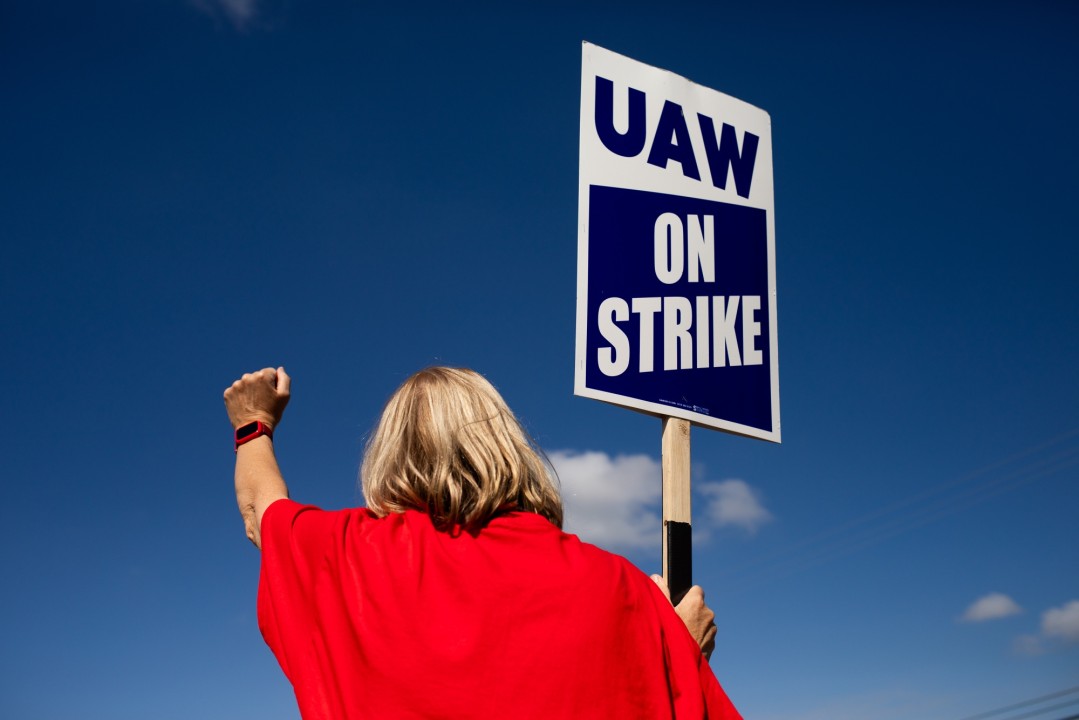

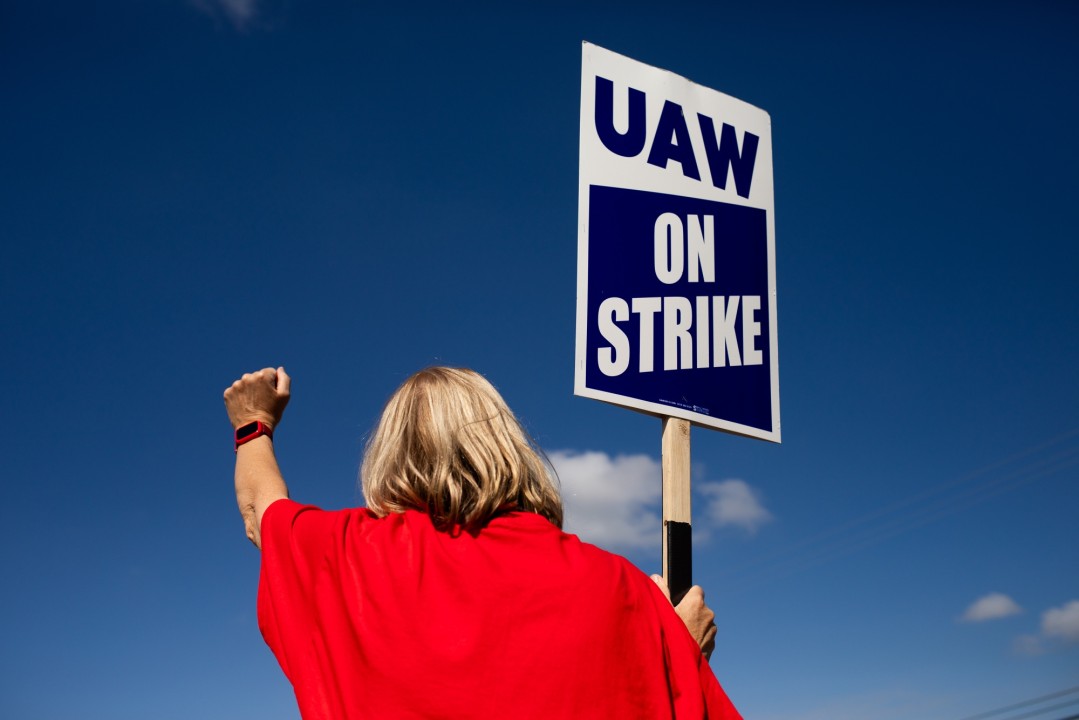

Actors And Writers Strike Hollywood Faces Unprecedented Production Shutdown

May 03, 2025

Actors And Writers Strike Hollywood Faces Unprecedented Production Shutdown

May 03, 2025 -

Aktualnye Mery Protivodeystviya Torgovle Lyudmi V Sogdiyskoy Oblasti

May 03, 2025

Aktualnye Mery Protivodeystviya Torgovle Lyudmi V Sogdiyskoy Oblasti

May 03, 2025 -

Fortnite Leaked Icon Skin Details Emerge

May 03, 2025

Fortnite Leaked Icon Skin Details Emerge

May 03, 2025