The Reality Of Reshoring Manufacturing Jobs To America

Table of Contents

The Economic Drivers of Reshoring

Several key economic factors are fueling the reshoring trend.

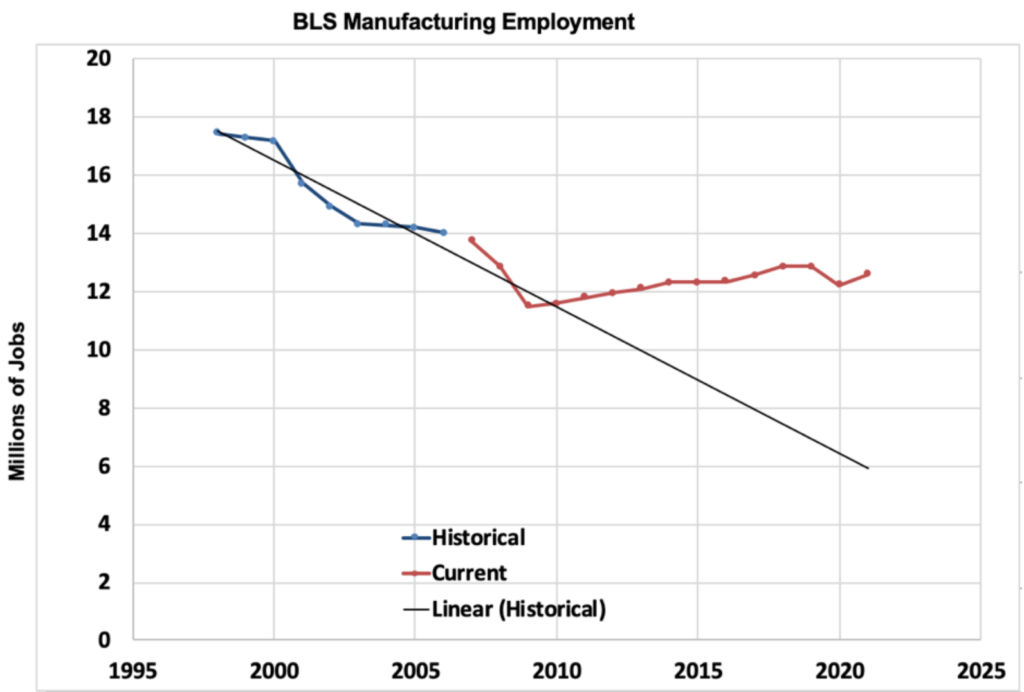

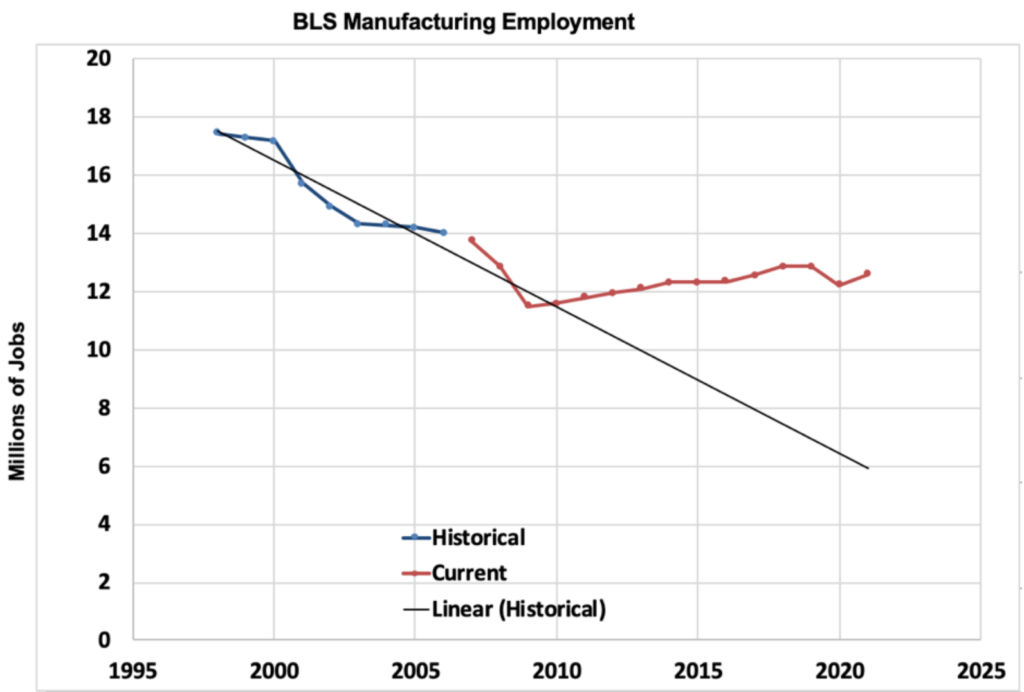

Rising Labor Costs Overseas

The era of incredibly cheap labor in countries like China is ending. Wages are steadily increasing, eroding the cost advantage that once drove offshoring.

- Examples of countries with rising labor costs: China, Vietnam, India.

- Comparisons to US labor costs: While US labor costs remain higher, the gap is narrowing, especially when considering increased productivity driven by automation and technological advancements. This makes the total cost of manufacturing more competitive.

- Impact on manufacturing profitability: The rising labor costs overseas are impacting the profitability of many manufacturing operations, making reshoring a more financially viable option.

Supply Chain Disruptions & Resilience

Recent global events, including the COVID-19 pandemic and geopolitical instability, have brutally exposed the vulnerabilities of overly complex and geographically dispersed global supply chains.

- Case studies of companies impacted by supply chain disruptions: Numerous companies experienced significant delays and shortages, highlighting the risks of relying on distant suppliers. The automotive industry, for example, faced significant chip shortages.

- Benefits of domestic production for resilience: Reshoring allows companies to shorten their supply chains, reducing reliance on vulnerable international links and improving responsiveness to disruptions.

- Examples of companies reshoring due to supply chain issues: Many manufacturers are actively diversifying their supply chains and bringing production closer to home to mitigate future risks.

Government Incentives and Policies

Government initiatives play a significant role in encouraging manufacturing reshoring. Tax breaks, subsidies, and other programs aim to incentivize companies to bring jobs back to the US.

- Specific examples of government initiatives supporting manufacturing: The Bipartisan Infrastructure Law, for example, invests billions in upgrading infrastructure, which is crucial for domestic manufacturing. Other programs offer tax credits for companies investing in domestic production.

- Analysis of their effectiveness: The effectiveness of these initiatives varies, and their impact needs continued monitoring and evaluation.

- Potential drawbacks: Some argue that government incentives distort the market and may not always lead to sustainable reshoring efforts.

Challenges and Obstacles to Reshoring

Despite the economic drivers, several significant hurdles remain in the path of successful reshoring.

Higher Labor Costs in the US

The higher labor costs in the US compared to some overseas locations remain a primary concern for businesses.

- Automation, increased productivity: Investments in automation and advanced technologies can significantly offset higher wages, improving overall efficiency and competitiveness.

- Potential for higher skilled jobs: Reshoring can lead to the creation of higher-skilled, better-paying jobs, benefiting the American workforce.

Infrastructure Limitations

Outdated and inadequate infrastructure – transportation networks, energy grids, and internet access – represents a significant challenge to reshoring efforts.

- Examples of infrastructure bottlenecks impacting manufacturing: Insufficient transportation capacity can lead to delays and increased costs. A lack of reliable energy supply can halt production.

- The cost of upgrading infrastructure: Upgrading infrastructure requires substantial investment, posing a challenge for both the public and private sectors.

- Potential solutions: Public-private partnerships and targeted infrastructure investments are crucial to address these limitations.

Skilled Labor Shortages

Finding and training a skilled workforce for advanced manufacturing roles is a major obstacle.

- Initiatives to address skills gaps: Apprenticeship programs, vocational training, and STEM education initiatives are vital to create a pipeline of skilled workers.

- Importance of STEM education: Investing in STEM education from an early age is crucial to develop the future workforce needed for advanced manufacturing.

Success Stories and Best Practices

Despite the challenges, numerous companies have successfully reshored manufacturing operations.

Case Studies of Successful Reshoring

Several companies have demonstrated the viability of reshoring.

- Company names: While specific company names may require further research for confidentiality reasons, case studies from various industries illustrate successful reshoring initiatives.

- Reasons for reshoring: Factors such as improved supply chain resilience, reduced transportation costs, and access to a more skilled workforce are frequently cited reasons.

- Results achieved: Successful reshoring has often led to job creation, cost savings, and increased efficiency.

Strategies for Successful Reshoring

Companies considering reshoring should adopt a strategic and phased approach.

- Thorough feasibility studies: Conducting thorough due diligence is crucial to understand the costs and benefits of reshoring.

- Strategic partnerships: Collaborating with local governments, educational institutions, and other stakeholders can facilitate a smooth transition.

- Investment in automation and technology: Leveraging automation and advanced technologies can boost productivity and offset higher labor costs.

- Workforce training programs: Investing in employee training and upskilling initiatives is crucial to build a capable workforce.

Conclusion

The reality of reshoring manufacturing jobs is complex. While rising overseas labor costs, supply chain disruptions, and government incentives are driving the trend, significant challenges related to US labor costs, infrastructure limitations, and skilled labor shortages remain. However, successful case studies demonstrate that strategic planning, investment in technology, and robust workforce development initiatives can pave the way for profitable and sustainable reshoring efforts. Ready to explore the benefits of reshoring manufacturing for your company? Contact us today to learn more about strategic reshoring strategies and government incentives to bring jobs back to America and strengthen American manufacturing.

Featured Posts

-

Fenerbahce Nin Tadic Operasyonu Talisca Tartismasinin Goelgesinde

May 20, 2025

Fenerbahce Nin Tadic Operasyonu Talisca Tartismasinin Goelgesinde

May 20, 2025 -

Why Is D Wave Quantum Inc Qbts Stock Falling In 2025

May 20, 2025

Why Is D Wave Quantum Inc Qbts Stock Falling In 2025

May 20, 2025 -

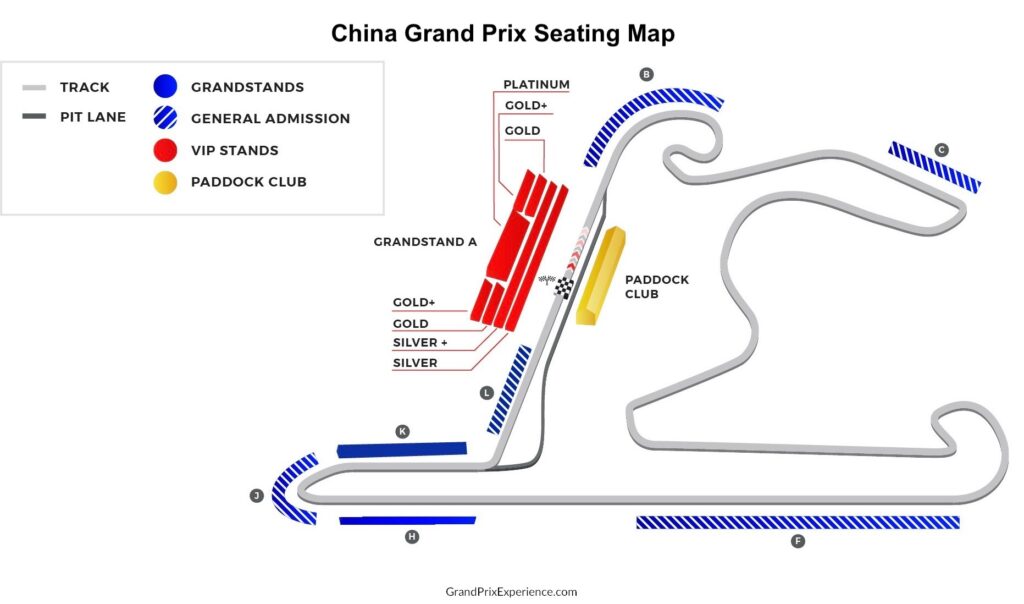

Hamilton And Leclerc Clash Impact On The Chinese Grand Prix

May 20, 2025

Hamilton And Leclerc Clash Impact On The Chinese Grand Prix

May 20, 2025 -

Za Kulisami Lda Biznes Interesy Plyuschenko Sikharulidze I Kuznetsovoy

May 20, 2025

Za Kulisami Lda Biznes Interesy Plyuschenko Sikharulidze I Kuznetsovoy

May 20, 2025 -

Report Wnba To Investigate Racial Slurs Aimed At Angel Reese

May 20, 2025

Report Wnba To Investigate Racial Slurs Aimed At Angel Reese

May 20, 2025

Latest Posts

-

D Wave Quantum Qbts Stock Market Activity Monday A Comprehensive Review

May 20, 2025

D Wave Quantum Qbts Stock Market Activity Monday A Comprehensive Review

May 20, 2025 -

Analysis Of D Wave Quantum Inc Qbts Stock Drop Mondays Market Activity

May 20, 2025

Analysis Of D Wave Quantum Inc Qbts Stock Drop Mondays Market Activity

May 20, 2025 -

Factors Contributing To D Wave Quantums Qbts Stock Fall On Monday

May 20, 2025

Factors Contributing To D Wave Quantums Qbts Stock Fall On Monday

May 20, 2025 -

Should You Invest In D Wave Quantum Inc Qbts A Quantum Computing Stock Analysis

May 20, 2025

Should You Invest In D Wave Quantum Inc Qbts A Quantum Computing Stock Analysis

May 20, 2025 -

Big Bear Ai Holdings Inc Bbai Stock Crash 17 87 Plunge Explained

May 20, 2025

Big Bear Ai Holdings Inc Bbai Stock Crash 17 87 Plunge Explained

May 20, 2025