The Potential Of Orbital Space Crystals For Enhanced Drug Production

Table of Contents

The Unique Properties of Space-Grown Crystals

The microgravity environment of space offers unparalleled advantages for crystal growth, leading to superior quality crystals compared to those grown on Earth. This superior quality directly translates to enhanced performance in various applications, including drug production.

Microgravity's Role

The absence of gravity profoundly influences crystal growth. On Earth, convection currents disrupt the even distribution of materials, leading to imperfections and lower-quality crystals. In microgravity, however, these disruptive forces are minimized.

- Improved crystal structure: The slow, undisturbed growth in microgravity results in larger crystals with fewer defects and a more homogenous structure.

- Enhanced homogeneity: The uniform distribution of materials throughout the crystal leads to consistent properties and improved performance.

- Reduced impurities: The controlled environment minimizes contamination, resulting in purer crystals with higher levels of active pharmaceutical ingredients (APIs).

This lack of convection allows for a slower, more controlled crystal growth process, resulting in larger, more perfect crystals. Proteins, for instance, often form more ordered crystals in microgravity, crucial for high-resolution X-ray crystallography.

Controlled Environment

Space-based crystal growth facilities offer a highly controlled environment, allowing for precise regulation of temperature, pressure, and other crucial parameters.

- Reduced contamination risks: The controlled environment minimizes the risk of contamination from airborne particles or other impurities, leading to exceptionally pure crystals.

- Enhanced reproducibility: The precise control of growth parameters ensures consistent and reproducible results, crucial for pharmaceutical manufacturing.

- Optimized growth conditions: Researchers can fine-tune growth conditions to achieve optimal crystal size, shape, and purity, maximizing yield and quality.

This level of control leads to higher yields of high-quality crystals compared to Earth-based methods, potentially offsetting the high launch costs in the long run through increased efficiency and reduced waste.

Applications in Drug Production

The superior quality of space-grown crystals holds immense promise for revolutionizing various aspects of drug production.

Protein Crystallization

Protein crystals are essential for determining the three-dimensional structure of proteins using X-ray crystallography. Space-grown protein crystals are often larger and more perfect than those grown on Earth.

- Improved resolution in X-ray crystallography: Higher-quality crystals provide significantly clearer images, leading to more accurate structural data.

- Facilitating drug design: Detailed structural information is crucial for designing drugs that interact specifically with target proteins.

- Enabling the study of protein-protein interactions: High-quality crystals enable researchers to study the interactions between proteins, providing valuable insights into biological processes and disease mechanisms.

This higher-resolution data accelerates the drug development process, potentially reducing development times and costs considerably.

Pharmaceutical Compound Synthesis

Beyond protein crystallization, space-grown crystals can serve as catalysts or precursors in the synthesis of novel pharmaceutical compounds.

- Potential for new drug discoveries: The unique environment of space may facilitate the synthesis of compounds not possible on Earth, opening avenues for new drug discoveries.

- Enhanced efficiency in existing processes: Space-grown crystals could improve the efficiency and yield of existing pharmaceutical synthesis processes.

- Synthesis of complex molecules not possible on Earth: The controlled environment and unique conditions in space could enable the synthesis of complex molecules with challenging reaction pathways.

For example, the synthesis of certain complex organic molecules, which are difficult to synthesize on Earth due to instability or challenging reaction conditions, might be significantly more efficient in the unique environment of space.

Challenges and Future Directions

Despite the immense potential, several challenges need to be addressed to realize the full potential of orbital space crystals for drug production.

Cost and Logistics

The high costs associated with launching materials into orbit and maintaining space-based facilities present significant hurdles.

- High launch costs: The cost of launching equipment and materials into space is currently a major limitation.

- Specialized equipment requirements: Space-based crystal growth requires specialized equipment designed to withstand the harsh environment of space.

- Maintenance challenges: Maintaining and repairing equipment in space is complex and expensive.

- Sample return complexities: The safe and efficient return of valuable space-grown crystals to Earth is crucial.

However, reusable spacecraft, automated systems, and international collaborations could help mitigate these costs and logistical challenges.

Scalability and Commercialization

Scaling up space-based crystal growth for commercial drug production requires significant advancements in technology and infrastructure.

- Development of larger-scale facilities in space: Larger facilities are needed to increase the production capacity of space-grown crystals.

- Automation of crystal growth processes: Automation is essential to reduce labor costs and increase efficiency.

- Establishing partnerships with pharmaceutical companies: Collaboration with pharmaceutical companies is crucial to translate research into commercial applications.

The potential return on investment is substantial, and a clear pathway towards commercial viability needs further development.

Conclusion

Utilizing orbital space crystals for enhanced drug production offers significant advantages, including improved purity, higher yields, the potential for groundbreaking new drug discoveries, and accelerated drug development. The superior quality of space-grown crystals translates to more effective and safer medicines. The key takeaways from this exploration highlight the transformative potential of this technology for the pharmaceutical industry and global healthcare. The challenges related to cost and scalability are significant, yet not insurmountable. Further research and development, coupled with strategic investments and international collaborations, are crucial to unlocking the full potential of space-based pharmaceutical manufacturing and improving global healthcare. The future of drug production may well depend on the success of this innovative approach.

Featured Posts

-

Demnas Influence Reshaping Guccis Identity And Brand Image

May 24, 2025

Demnas Influence Reshaping Guccis Identity And Brand Image

May 24, 2025 -

Tracking The Nav Amundi Dow Jones Industrial Average Ucits Etf Distribution

May 24, 2025

Tracking The Nav Amundi Dow Jones Industrial Average Ucits Etf Distribution

May 24, 2025 -

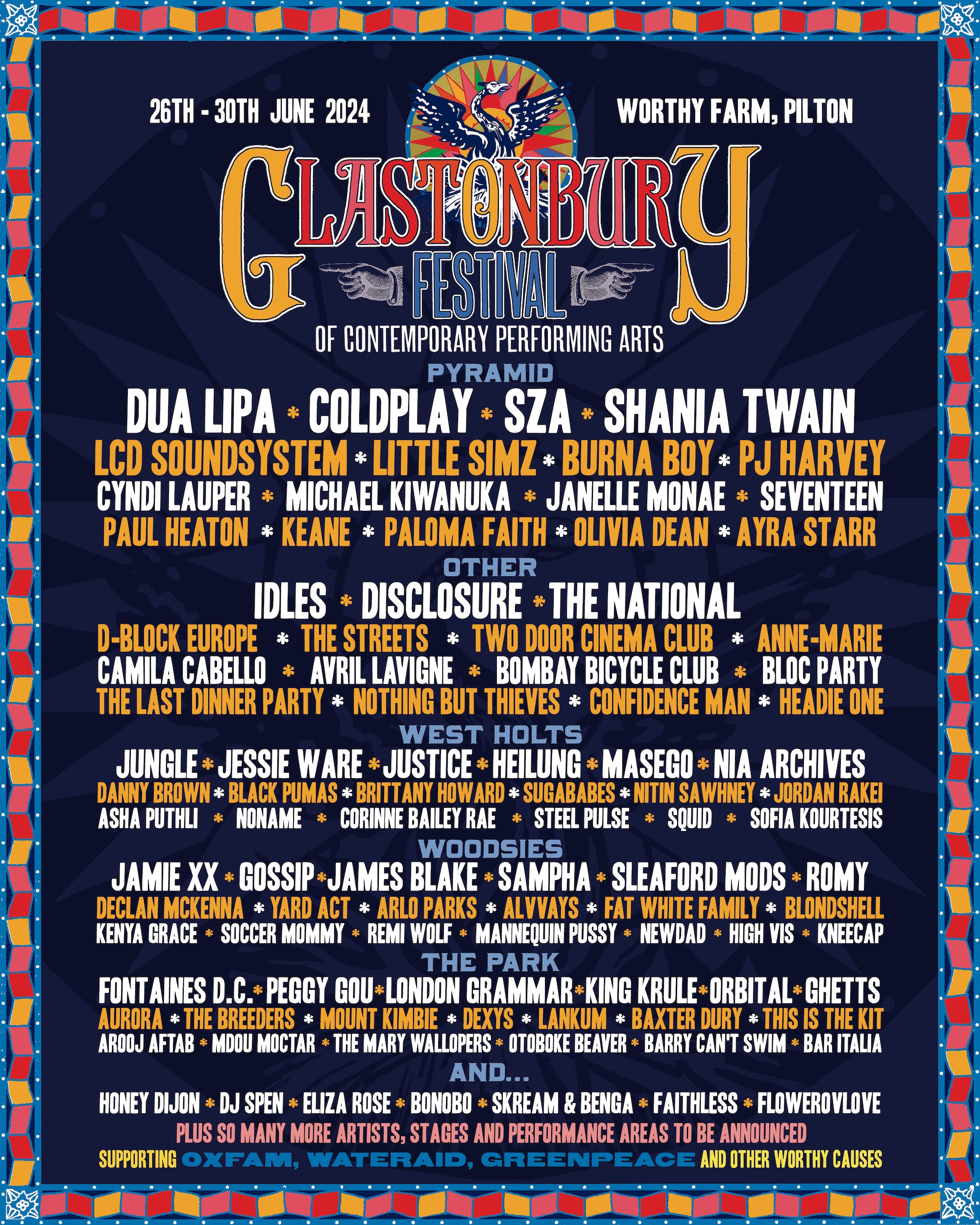

Official Glastonbury 2025 Lineup Where To Get Tickets Following Leak

May 24, 2025

Official Glastonbury 2025 Lineup Where To Get Tickets Following Leak

May 24, 2025 -

Astonishing Police Chase Pair Refuels At 90mph

May 24, 2025

Astonishing Police Chase Pair Refuels At 90mph

May 24, 2025 -

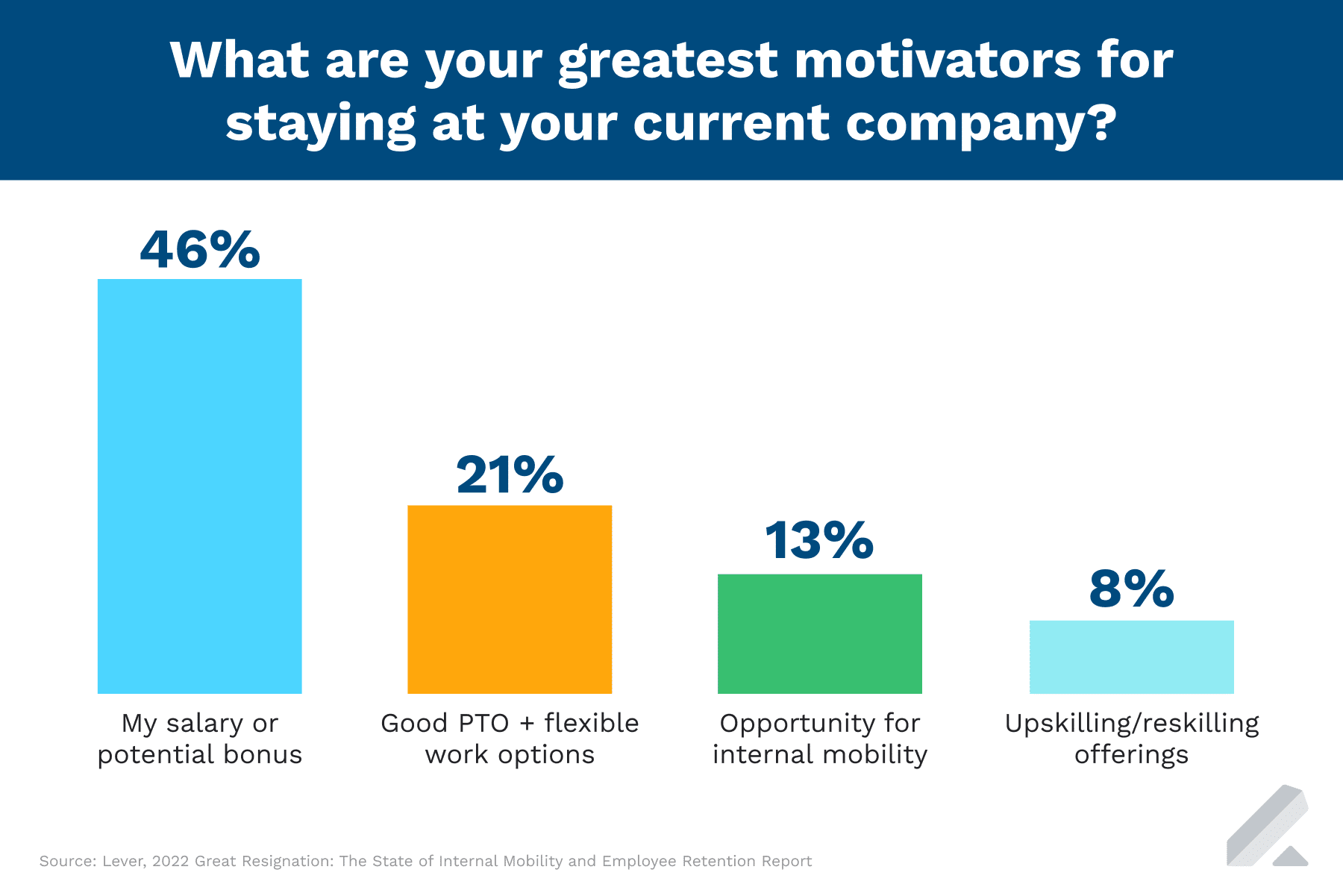

Investing In Middle Management A Key To Improved Productivity And Employee Retention

May 24, 2025

Investing In Middle Management A Key To Improved Productivity And Employee Retention

May 24, 2025

Latest Posts

-

Kubok Billi Dzhin King Kazakhstan V Finale Tretiy Raz Za Istoriyu

May 24, 2025

Kubok Billi Dzhin King Kazakhstan V Finale Tretiy Raz Za Istoriyu

May 24, 2025 -

Kazakhstan Defeats Australia In Billie Jean King Cup Qualifying Tie

May 24, 2025

Kazakhstan Defeats Australia In Billie Jean King Cup Qualifying Tie

May 24, 2025 -

Vilius Gaubass Italian Open Victory Over Denis Shapovalov

May 24, 2025

Vilius Gaubass Italian Open Victory Over Denis Shapovalov

May 24, 2025 -

Aleksandrova Samsonova Itogi Matcha Pervogo Kruga V Shtutgarte

May 24, 2025

Aleksandrova Samsonova Itogi Matcha Pervogo Kruga V Shtutgarte

May 24, 2025 -

Kazakhstan Probilsya V Final Kubka Billi Dzhin King Tretiy Raz

May 24, 2025

Kazakhstan Probilsya V Final Kubka Billi Dzhin King Tretiy Raz

May 24, 2025