The High Cost Of Making An All-American Product

Table of Contents

Soaring Labor Costs in the United States

The cost of labor in the US significantly impacts the price of an All-American product. Two key factors contribute to this: rising minimum wages and benefits packages, and persistent skilled labor shortages.

Minimum Wage Increases and Benefits Packages

Minimum wage increases across many states have undeniably raised labor costs. Furthermore, providing comprehensive employee benefits, including healthcare and retirement plans, adds a substantial layer of expense.

- Examples of high minimum wage states: California, New York, and Washington have seen significant minimum wage increases in recent years, directly affecting businesses' bottom lines.

- Impact on small businesses: Smaller manufacturers often struggle to absorb these increased costs, potentially leading to reduced hiring or even business closures.

- Comparison to labor costs in other countries: The cost of labor in the US remains significantly higher than in many other countries, creating a considerable disadvantage for domestic manufacturers competing in the global market.

Skilled Labor Shortages

A critical challenge facing American manufacturing is the shortage of skilled workers. Finding and retaining individuals with expertise in areas like robotics, programming, and specialized machining is difficult and costly.

- Examples of in-demand skills: CNC machining, welding, industrial automation, and software programming are just some of the skills experiencing high demand.

- Strategies to attract and train workers: Apprenticeship programs, vocational training initiatives, and partnerships with educational institutions are crucial for developing a skilled workforce.

- The impact of automation: While automation can improve efficiency, the initial investment costs and the need for skilled technicians to maintain and operate the equipment can also impact overall production expenses.

The Price of Raw Materials and Supply Chain Disruptions

The cost of raw materials and the vulnerabilities of global supply chains significantly contribute to the high price of an All-American product.

Increased Domestic Material Costs

Sourcing raw materials domestically is often more expensive than importing them. Several factors contribute to this.

- Examples of specific materials: Steel, lumber, and cotton are just a few examples of raw materials experiencing price volatility.

- Factors influencing price fluctuations: Global demand, resource scarcity, and increasingly stringent environmental regulations all affect the cost of raw materials.

Supply Chain Vulnerabilities

Recent global events have highlighted the fragility of supply chains. Disruptions can lead to significant delays and increased costs.

- Examples of recent supply chain issues: The COVID-19 pandemic, geopolitical instability, and natural disasters have all exposed vulnerabilities in global supply chains.

- Strategies for diversification of suppliers: American manufacturers are increasingly seeking to diversify their supplier base to reduce reliance on single sources and mitigate risk.

- The role of technology in improving supply chain resilience: Technological advancements, such as blockchain and AI, are being used to improve transparency and efficiency in supply chains.

Stringent US Regulations and Compliance Costs

The US has stringent regulations regarding environmental protection and workplace safety, adding to the cost of production.

Environmental Regulations

Compliance with Environmental Protection Agency (EPA) regulations requires significant investment in clean technology and sustainable practices.

- Examples of specific environmental regulations: Regulations related to air and water pollution, hazardous waste disposal, and greenhouse gas emissions impose substantial costs on manufacturers.

- Investment in clean technology: Adopting cleaner technologies, while environmentally beneficial, often requires substantial upfront investment.

- Carbon footprint reduction strategies: Companies are increasingly adopting strategies to minimize their carbon footprint, adding further cost to the manufacturing process.

Safety and Labor Regulations

Adherence to Occupational Safety and Health Administration (OSHA) standards and other labor laws also adds to the overall cost.

- OSHA compliance: Implementing and maintaining safety protocols, providing worker training, and investing in safety equipment are all necessary but costly expenses.

- Worker safety training: Regular training programs are essential to ensure a safe working environment, adding to labor costs.

- Insurance costs: Comprehensive insurance coverage to protect against workplace accidents and injuries adds significantly to the overall expenses.

The Competitive Landscape: Globalized Markets and Import Competition

The globalized nature of markets presents a significant challenge to American manufacturers.

Lower Manufacturing Costs Overseas

Many countries offer significantly lower labor and material costs, making it difficult for US manufacturers to compete on price alone.

- Examples of countries with lower labor and material costs: China, Vietnam, and Mexico are examples of countries with lower manufacturing costs.

- The role of trade agreements: Trade agreements can impact the competitiveness of American manufacturers by influencing import tariffs and quotas.

- Impact on pricing and market share: The lower production costs in other countries often allow foreign manufacturers to offer products at lower prices, affecting the market share of American-made goods.

Consumer Preferences and Price Sensitivity

Consumers are often price-sensitive, favoring lower-priced goods, even if they are not made in the USA.

- Consumer buying habits: Price remains a major factor influencing consumer buying decisions.

- The role of branding and perceived value: Strong branding and emphasizing the quality and value proposition of All-American products can help offset higher prices.

- Strategies for maintaining market share despite higher prices: Focusing on niche markets, emphasizing superior quality and craftsmanship, and leveraging the "Made in the USA" label as a selling point can help American manufacturers maintain market share.

Conclusion

Producing an All-American product is undeniably more expensive than manufacturing in many other parts of the world. This is due to a combination of factors: higher labor costs, the price of domestic raw materials, stringent regulations, and intense competition from lower-cost producers. Maintaining competitiveness while adhering to high standards of quality, safety, and environmental responsibility is a significant challenge for American manufacturers. Supporting the production of truly All-American goods requires understanding the cost of a genuine All-American product and making informed decisions about All-American-made items. Let's actively choose to support domestic manufacturers and contribute to a thriving American economy by recognizing and valuing the higher cost of quality and responsible production.

Featured Posts

-

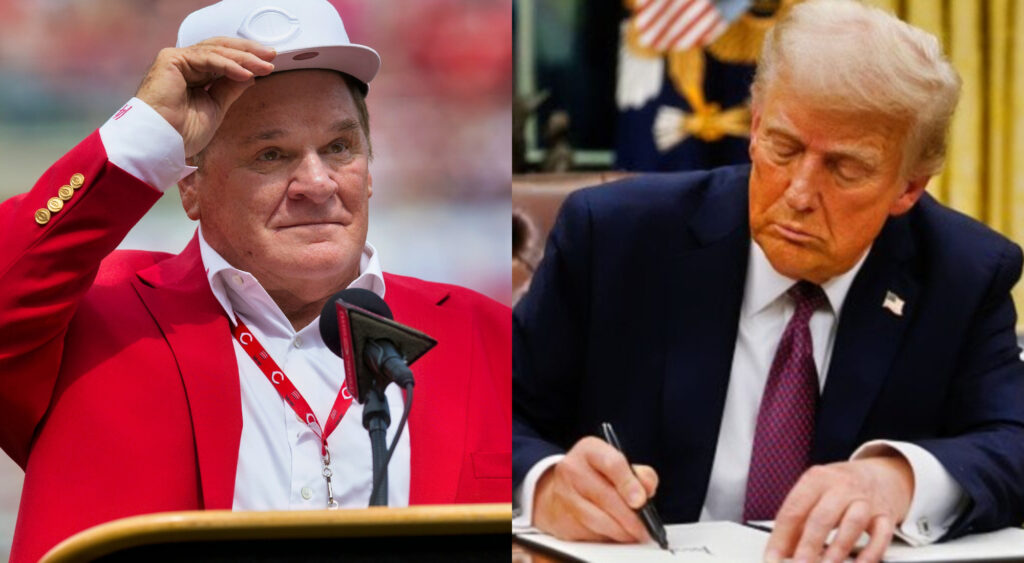

The Pete Rose Pardon Debate Trump Baseball And The Legacy Of A Ban

Apr 29, 2025

The Pete Rose Pardon Debate Trump Baseball And The Legacy Of A Ban

Apr 29, 2025 -

Akeso Shares Fall Following Unsuccessful Cancer Drug Trial

Apr 29, 2025

Akeso Shares Fall Following Unsuccessful Cancer Drug Trial

Apr 29, 2025 -

Rekordiniai Porsche Pardavimai Lietuvoje 2024 Metais

Apr 29, 2025

Rekordiniai Porsche Pardavimai Lietuvoje 2024 Metais

Apr 29, 2025 -

Nyt Spelling Bee February 12 2025 Solutions And Pangram

Apr 29, 2025

Nyt Spelling Bee February 12 2025 Solutions And Pangram

Apr 29, 2025 -

Investigation Continues Into Disappearance Of British Paralympian Sam Ruddock In Las Vegas

Apr 29, 2025

Investigation Continues Into Disappearance Of British Paralympian Sam Ruddock In Las Vegas

Apr 29, 2025