The Future Of Electric Motors: Diversifying Supply Chains Away From China

Table of Contents

Geopolitical Risks of China's Dominance in Electric Motor Manufacturing

Over-dependence on any single nation for critical components, especially those as vital as electric motors, presents significant geopolitical risks. China's current position in the market creates several potential vulnerabilities.

Trade Wars and Tariffs

Trade disputes can significantly impact the cost and availability of electric motors. Past trade tensions, such as the US-China trade war, have demonstrated the fragility of supply chains concentrated in a single region.

- Example 1: Tariffs imposed on Chinese-manufactured goods led to increased costs for electric motor imports, impacting the profitability of companies reliant on these components.

- Example 2: Trade restrictions resulted in significant delays in the delivery of electric motors, disrupting production schedules and causing unforeseen expenses. These increased costs and unpredictable delays highlight the crucial need for diversified sourcing.

Political Instability and Supply Chain Disruptions

Political instability within China, or unexpected geopolitical events affecting the country, could severely disrupt production and shipping of electric motors, causing widespread economic consequences.

- Potential for internal political unrest to halt manufacturing.

- Risk of export restrictions or disruptions due to international conflicts.

- The inherent vulnerability of relying on a single point of production for such a critical component. This necessitates building redundancy and resilience into the supply chain, mitigating the impact of potential disruptions.

Intellectual Property Concerns

Intellectual property (IP) theft is a significant concern in certain manufacturing sectors, posing a considerable risk for companies investing heavily in electric motor technology.

- Numerous instances of IP theft have been reported in related technology sectors within China.

- Protecting innovative designs and proprietary technologies is paramount to maintaining a competitive edge. Diversifying manufacturing locations and establishing strong IP protection agreements are vital for safeguarding technological advancements.

Strategies for Diversifying Electric Motor Supply Chains

Mitigating the risks associated with China's dominance requires a multifaceted approach, focusing on diversifying manufacturing and strengthening domestic capabilities.

Reshoring and Nearshoring

Bringing electric motor manufacturing closer to home (reshoring) or to neighboring countries (nearshoring) offers several compelling advantages.

- Reduced transportation costs and lead times: This improves efficiency and reduces the environmental impact of shipping.

- Improved control over quality and production processes: This ensures consistent standards and minimizes disruptions.

- Increased job creation in domestic or regional markets: This stimulates economic growth and strengthens national security. Companies like Tesla are already demonstrating the feasibility and benefits of reshoring certain aspects of their production.

Investing in Alternative Manufacturing Hubs

Several countries are emerging as potential alternatives for electric motor manufacturing.

- Southeast Asia (Vietnam, Thailand, etc.): Offers lower labor costs and growing infrastructure.

- India: A large and expanding market with a skilled workforce.

- Mexico: Proximity to the US market and established manufacturing capabilities.

- European Union: Strong regulatory frameworks and focus on sustainable manufacturing. Governments in these regions are actively investing in incentives and policies to attract electric motor manufacturers.

Fostering Domestic Production and Technological Advancements

Government support and private investment are crucial for building a robust domestic electric motor industry.

- Government funding for research and development (R&D) in electric motor technology.

- Tax incentives and subsidies to encourage domestic manufacturing.

- Investments in workforce training and education to develop a skilled workforce. Investing in domestic capabilities not only reduces reliance on foreign suppliers but also fosters innovation and technological leadership.

The Role of Automation and Technology in Diversification

Automation and advanced technologies play a significant role in enabling supply chain diversification and enhancing resilience.

Automation and Robotics

Automating various stages of electric motor manufacturing can significantly enhance efficiency, reduce labor costs, and improve production consistency across different geographical locations.

- Automated assembly lines can increase production speed and reduce errors.

- Robotic systems can handle repetitive tasks, improving productivity.

- Automated quality control systems can ensure consistent standards regardless of manufacturing location.

AI and Predictive Analytics

Artificial intelligence (AI) and predictive analytics can optimize supply chains, forecast demand, and mitigate risks.

- AI-powered inventory management systems can optimize stock levels and reduce waste.

- Predictive analytics can identify potential disruptions in the supply chain, allowing for proactive mitigation.

- AI-driven risk assessment can help companies make informed decisions about sourcing and manufacturing.

Additive Manufacturing (3D Printing)

3D printing, or additive manufacturing, holds significant potential for decentralizing electric motor production.

- 3D printing allows for localized production of components, reducing reliance on centralized supply chains.

- It enables customization and faster prototyping, accelerating innovation.

- While still in its early stages for large-scale production, 3D printing is rapidly advancing and could revolutionize the industry.

Conclusion

The over-reliance on China for electric motor components presents significant geopolitical and economic risks. Diversifying supply chains is crucial for building a more resilient and secure electric motor industry. By strategically investing in reshoring, nearshoring, alternative manufacturing hubs, domestic production, and advanced technologies like automation and AI, we can create a more robust and globally distributed ecosystem. The future of electric motors depends on this proactive approach. Join the movement towards a more resilient and diversified electric motor industry. Learn more about the latest developments in electric motor technology and supply chain strategies today!

Featured Posts

-

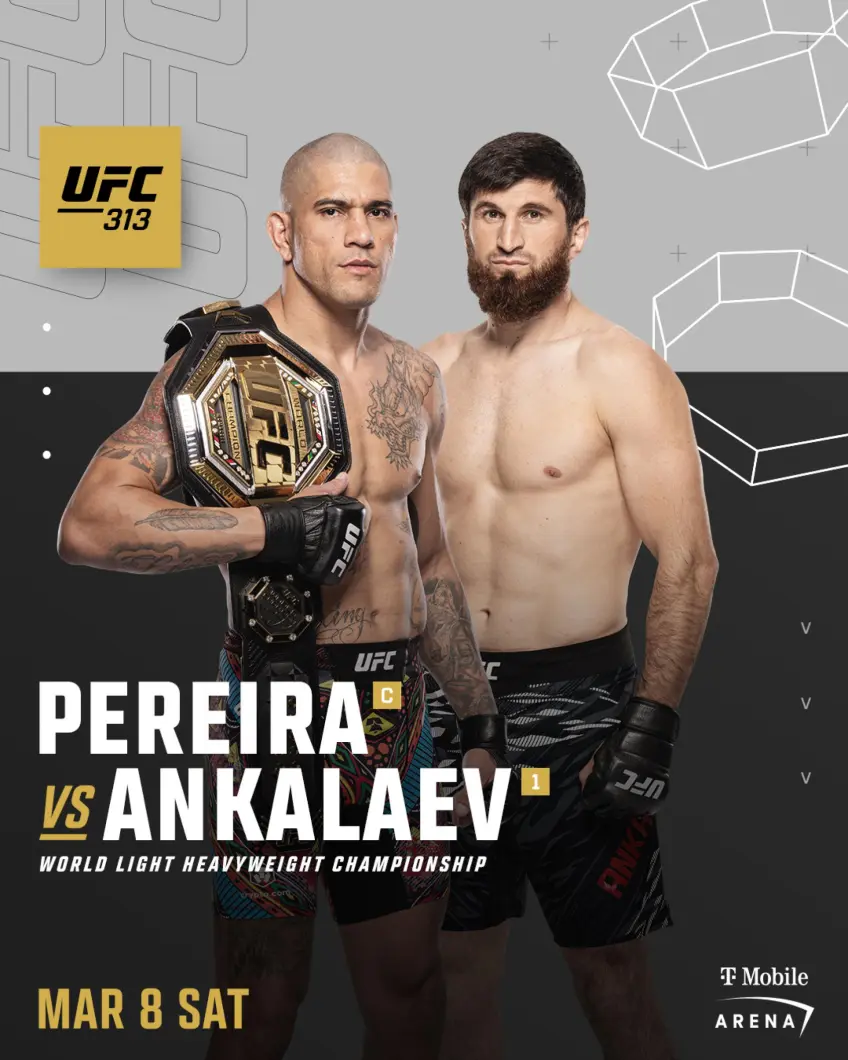

Ufc 313 Pereira Vs Ankalaev Dfs Picks And Predictions

May 04, 2025

Ufc 313 Pereira Vs Ankalaev Dfs Picks And Predictions

May 04, 2025 -

Farage Faces Backlash Criticism Mounts Over Zelenskyy Remarks

May 04, 2025

Farage Faces Backlash Criticism Mounts Over Zelenskyy Remarks

May 04, 2025 -

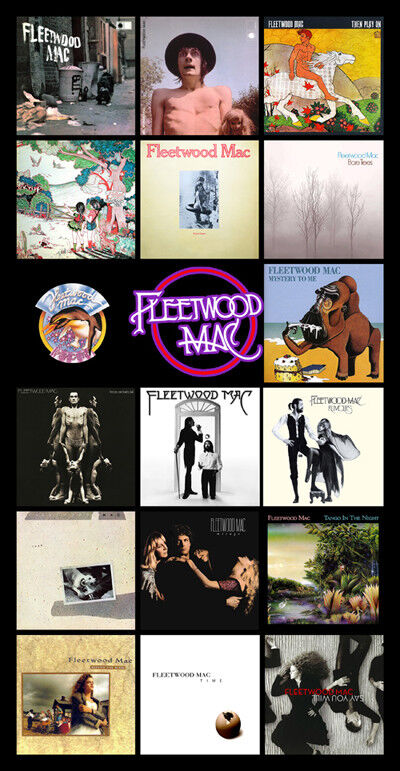

Fleetwood Macs Bestselling Albums A Look At Their Extensive Discography

May 04, 2025

Fleetwood Macs Bestselling Albums A Look At Their Extensive Discography

May 04, 2025 -

Berenger Thouins Directorial Debut L Age D Or Begins Filming

May 04, 2025

Berenger Thouins Directorial Debut L Age D Or Begins Filming

May 04, 2025 -

Kanye Wests Controversial Bianca Censori Film Promotion

May 04, 2025

Kanye Wests Controversial Bianca Censori Film Promotion

May 04, 2025