The Challenges Of Producing All-American Goods

Table of Contents

The resurgence of "Made in America" products is a powerful trend, fueled by a desire for quality, sustainability, and support for domestic jobs. However, the path to producing truly all-American goods is far from easy. Manufacturers face significant hurdles, creating a complex landscape that requires careful navigation. This article explores the key economic, logistical, and regulatory challenges that impact the ability of companies to keep their entire production process within US borders.

<h2>High Labor Costs and Reduced Manufacturing Competitiveness</h2>

One of the most significant challenges in producing all-American goods is the disparity in labor costs between the US and many global manufacturing powerhouses. This impacts profitability and competitiveness in the global marketplace.

<h3>The Wage Gap</h3>

The US boasts significantly higher labor costs than countries like China, Vietnam, or Mexico. This wage gap directly influences the final price of goods.

- Minimum wage variations across states: The minimum wage differs significantly across US states, impacting labor costs regionally.

- Unionization costs: Unionized workplaces often involve higher labor costs due to union dues, benefits, and negotiated wages.

- Employee benefits packages: US companies typically offer more comprehensive employee benefits packages, including health insurance, retirement plans, and paid time off, adding to labor expenses.

For example, the average hourly manufacturing wage in the US significantly surpasses that of its global competitors. This difference translates directly to increased production costs for American-made goods, making them less price-competitive on the international stage. A comprehensive analysis of these cost differences is crucial for understanding the challenges faced by domestic manufacturers.

<h3>Automation's Role</h3>

While automation offers a potential solution to mitigate some labor cost increases, it comes with its own set of complexities.

- Initial investment costs: Implementing automated systems requires substantial upfront capital investment.

- Maintenance costs: Ongoing maintenance and repairs are necessary, contributing to long-term expenses.

- Ongoing technological upgrades: Technology rapidly evolves; manufacturers must budget for upgrades to remain competitive.

- Skilled labor needed: Operating and maintaining sophisticated automated systems requires highly skilled technicians, which can be expensive to hire and retain.

Although automation can improve efficiency and reduce reliance on manual labor in certain aspects of the manufacturing process, the initial and ongoing investment can be a significant barrier to entry, especially for smaller American manufacturers. A careful assessment of the return on investment (ROI) for automation is critical before implementation.

<h2>Supply Chain Disruptions and Sourcing Domestic Materials</h2>

Another significant hurdle is the challenge of sourcing all necessary raw materials domestically. This affects both the availability and cost of production.

<h3>Raw Material Availability</h3>

Securing all raw materials within the US presents considerable difficulties. Many specialized components or rare earth minerals are simply not readily available in sufficient quantities within the country.

- Dependence on foreign suppliers: American manufacturers often rely on foreign suppliers for certain raw materials, creating vulnerability to global supply chain disruptions.

- Transportation costs: Shipping raw materials across the country can be costly, adding to overall production expenses.

- Inconsistency of domestic supply: Domestic sources may not be able to provide consistent, reliable supplies, potentially disrupting production schedules.

The limited availability of certain crucial raw materials within the US necessitates reliance on imports, undermining the goal of completely domestic production. This dependency exposes manufacturers to global market fluctuations and geopolitical uncertainties.

<h3>Transportation and Logistics</h3>

Domestic transportation costs can significantly impact the competitiveness of "Made in America" products. Moving goods across vast distances within the US can be considerably more expensive than importing from overseas.

- Fuel costs: Fluctuating fuel prices directly impact transportation costs.

- Trucking limitations: Truck driver shortages and capacity constraints can delay shipments and increase expenses.

- Infrastructure bottlenecks: Congestion at ports, roads, and railways can lead to delays and increased costs.

- Distances between manufacturing facilities and distribution centers: The sheer geographical size of the US necessitates long-distance transportation for many goods.

The high cost of domestic transportation often negates the perceived benefits of producing goods domestically, especially when compared to the relatively low cost of shipping from overseas manufacturing hubs. Improving domestic infrastructure and streamlining logistics are crucial for making “Made in America” more economically viable.

<h2>Regulatory Compliance and Environmental Concerns</h2>

The US has stringent environmental regulations and complex trade policies, which add significant costs to manufacturing.

<h3>Environmental Regulations</h3>

Meeting US environmental regulations is vital, but it comes at a price. Compliance can significantly increase manufacturing expenses.

- Compliance costs: Meeting EPA standards requires investment in specialized equipment and processes.

- Waste disposal: Proper waste disposal and recycling add to operational costs.

- Emissions standards: Complying with strict emissions standards can necessitate costly upgrades to manufacturing equipment.

- Water usage restrictions: Water usage restrictions in some regions can increase production costs and complexity.

Stringent environmental regulations, while essential for protecting the environment, add a substantial financial burden on American manufacturers, making it more challenging to compete with businesses in countries with less strict regulations.

<h3>Trade Restrictions and Tariffs</h3>

Navigating trade policies and tariffs presents further complexities for manufacturers striving for all-American production.

- Import tariffs on raw materials: Tariffs on imported raw materials increase production costs.

- Export restrictions: Export restrictions can limit the ability to sell goods internationally.

- Changing trade agreements: Fluctuating trade agreements create uncertainty and potential cost increases.

- Compliance with import/export regulations: Navigating complex import and export regulations adds administrative overhead and costs.

The unpredictable nature of trade policies and tariffs creates significant challenges for manufacturers planning long-term production strategies. The constant need to adapt to changing regulations adds complexity and administrative overhead, increasing costs and reducing profitability.

<h2>Conclusion</h2>

Producing all-American goods presents numerous significant challenges, encompassing high labor costs, the complexities of sourcing domestic materials, and navigating a demanding regulatory environment. The "Made in America" movement is laudable, but achieving this goal requires careful consideration of the economic realities. Overcoming these hurdles requires a strategic approach that balances the economic imperatives with the social and environmental benefits of supporting domestic manufacturing. By understanding these challenges, businesses can better position themselves to thrive and contribute to the growth of truly All-American goods, revitalizing American manufacturing and ensuring its competitiveness in the global market.

Featured Posts

-

Fn Abwzby 2023 Afttah 19 Nwfmbr

Apr 29, 2025

Fn Abwzby 2023 Afttah 19 Nwfmbr

Apr 29, 2025 -

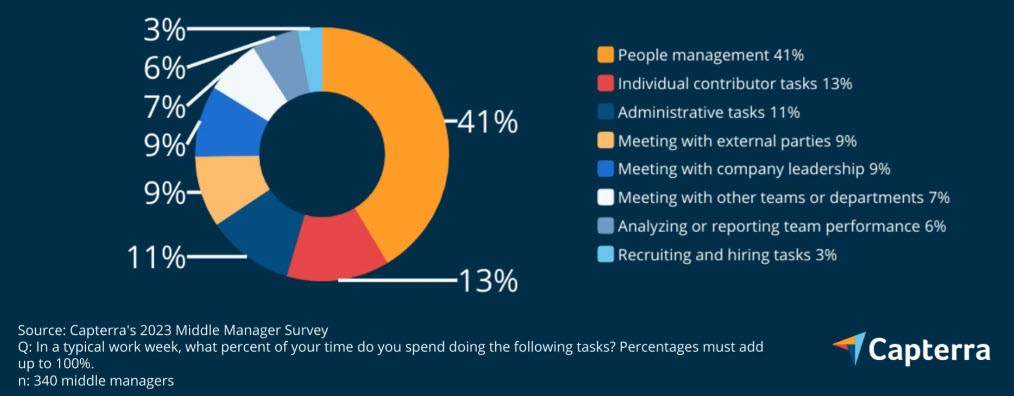

The Importance Of Middle Managers In Achieving Business Objectives

Apr 29, 2025

The Importance Of Middle Managers In Achieving Business Objectives

Apr 29, 2025 -

Adhd And Group Support A Powerful Combination For Success

Apr 29, 2025

Adhd And Group Support A Powerful Combination For Success

Apr 29, 2025 -

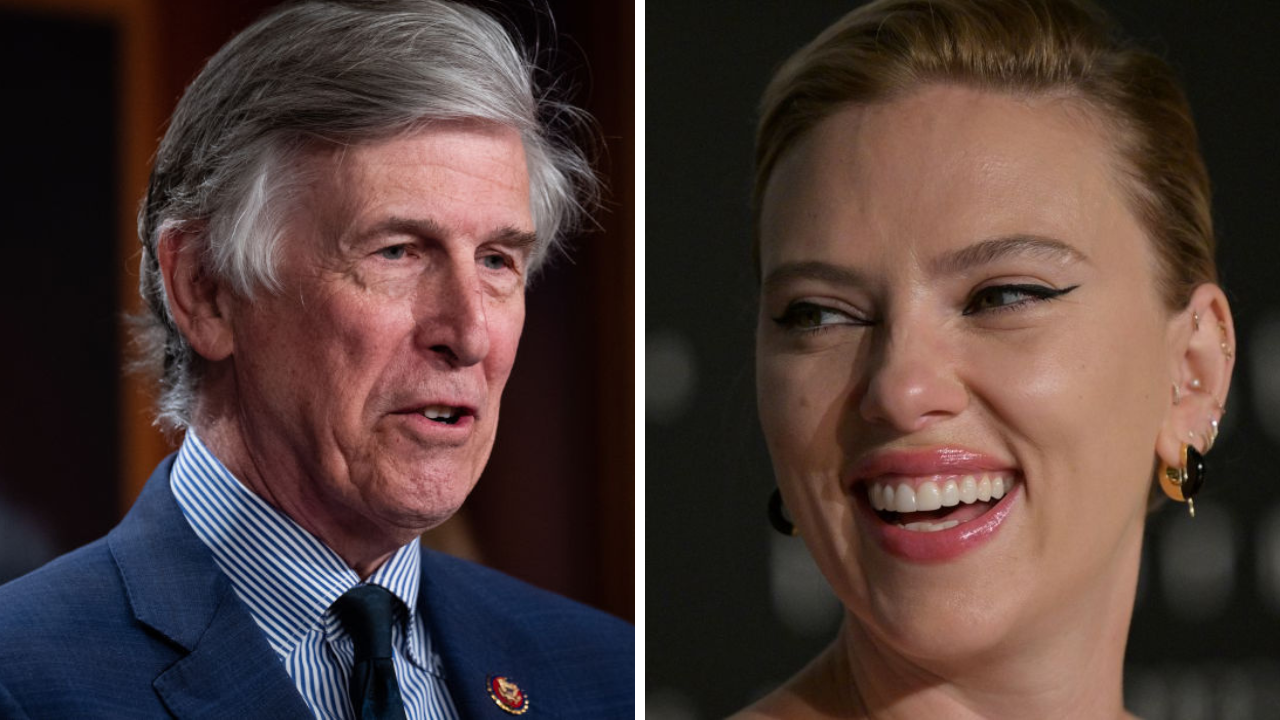

Usps Mail Delays Louisville Congressman Highlights Transparency Concerns

Apr 29, 2025

Usps Mail Delays Louisville Congressman Highlights Transparency Concerns

Apr 29, 2025 -

January 6th And The Epps Fox News Defamation Case A Deep Dive Into The Allegations

Apr 29, 2025

January 6th And The Epps Fox News Defamation Case A Deep Dive Into The Allegations

Apr 29, 2025