Steel Industry Decarbonization: The EraLow Solution From Eramet

Table of Contents

Understanding the Challenges of Steel Industry Decarbonization

Traditional steelmaking, primarily using the blast furnace-basic oxygen furnace (BF-BOF) route, is inherently carbon-intensive. This process relies heavily on coal-based coke for iron ore reduction, resulting in substantial CO2 emissions. The environmental impact of these emissions is far-reaching, contributing to climate change and air pollution. The urgency for decarbonization efforts is undeniable, driven by increasingly stringent environmental regulations globally, growing consumer demand for low-carbon steel products, and the imperative to mitigate the climate crisis.

- High CO2 emissions from coke production: Coke production is a major source of CO2 emissions in traditional steelmaking.

- Significant energy consumption in traditional steelmaking: The BF-BOF route is energy-intensive, further exacerbating the carbon footprint.

- Growing demand for low-carbon steel products: Consumers and industries are increasingly demanding steel produced with lower environmental impact.

- Stringent emission reduction targets from governments and consumers: Governments worldwide are implementing stricter regulations to curb emissions from the steel industry.

The eraLow Process: A Technological Breakthrough

Eramet's eraLow technology represents a significant departure from traditional steelmaking methods. It's a direct reduction process that significantly reduces reliance on coal and coke, replacing them with hydrogen and potentially other renewable energy sources. This fundamental shift enables a dramatic decrease in CO2 emissions. While specific quantifiable data may vary depending on the configuration and energy sources used, eraLow promises a substantial reduction compared to traditional methods.

- Reduced reliance on coal and coke: The eraLow process minimizes the use of fossil fuels, a key factor in reducing emissions.

- Increased use of hydrogen in the reduction process: Hydrogen, a clean energy carrier, plays a pivotal role in the eraLow process, enabling significant decarbonization.

- Potential for integration with renewable energy sources: Eramet's process is designed to integrate seamlessly with renewable energy sources, further reducing its carbon footprint.

- Improved energy efficiency compared to traditional methods: EraLow boasts improved energy efficiency, resulting in lower overall emissions per tonne of steel.

- Lower greenhouse gas emissions per tonne of steel produced: This is the core benefit of eraLow, directly addressing the major environmental concern of the steel industry.

Benefits and Advantages of eraLow for the Steel Industry

The adoption of eraLow offers substantial benefits across economic, environmental, and social dimensions. Economically, while initial investment may be higher, the long-term cost savings through reduced energy consumption and minimized carbon taxes can significantly enhance profitability and competitiveness. Environmentally, the reduced carbon footprint directly contributes to a more sustainable future. Socially, the transition to eraLow can create new jobs in the green technology sector and foster community engagement around sustainable development initiatives.

- Lower production costs in the long run: Reduced energy consumption and lower carbon taxes translate to cost savings over the lifecycle of the process.

- Enhanced brand reputation and market appeal: Producing low-carbon steel enhances a company's brand image and attractiveness to environmentally conscious consumers.

- Compliance with stricter environmental regulations: eraLow ensures compliance with increasingly stringent emission reduction targets.

- Contribution to a circular economy: The process aims to optimize resource utilization and minimize waste, supporting a circular economy model.

- Improved environmental, social, and governance (ESG) performance: Implementing eraLow greatly enhances a company's ESG rating, attracting responsible investors.

Future Prospects and Scalability of eraLow

Eramet is actively pursuing the commercialization and scaling of the eraLow technology. This involves strategic partnerships and collaborations with steel producers worldwide to accelerate the adoption of this innovative solution. The potential impact of eraLow on the global steel industry is transformative, offering a realistic pathway towards a decarbonized steel sector and contributing significantly to global climate goals.

- Plans for industrial-scale deployment of eraLow: Eramet is actively working on deploying eraLow at an industrial scale, demonstrating its viability and scalability.

- Collaboration with steel producers to implement the technology: Eramet is engaging with steel manufacturers to facilitate the adoption of eraLow in their production processes.

- Potential for licensing and technology transfer: Eramet is exploring licensing and technology transfer agreements to expand the global reach of eraLow.

- Long-term vision for a decarbonized steel industry: Eramet's vision is to contribute to a future where steel production is significantly less carbon-intensive.

Conclusion

Eramet's eraLow process represents a pivotal advancement in steel industry decarbonization. By substantially reducing CO2 emissions, and offering compelling economic and environmental advantages, eraLow is poised to revolutionize steel production. The future of sustainable steelmaking is becoming a reality thanks to innovative technologies like eraLow. Embracing such advancements is crucial for achieving a greener and more sustainable future. Learn more about Eramet's commitment to steel industry decarbonization and the potential of the eraLow process by visiting [link to Eramet's website]. Join the movement towards sustainable steel production with Eramet's eraLow solution.

Featured Posts

-

Oqtf Deux Collegiens Et Leur Mere Expulses Laissant Leurs Amis Sous Le Choc

May 14, 2025

Oqtf Deux Collegiens Et Leur Mere Expulses Laissant Leurs Amis Sous Le Choc

May 14, 2025 -

Pokemon Go Raids April 2025 Boss Lineup

May 14, 2025

Pokemon Go Raids April 2025 Boss Lineup

May 14, 2025 -

Nottingham Forests Striker Shortage A Crucial Summer Signing Needed

May 14, 2025

Nottingham Forests Striker Shortage A Crucial Summer Signing Needed

May 14, 2025 -

Celta Vs Sevilla Resumen Y Resultado De La Fecha 35 De La Liga

May 14, 2025

Celta Vs Sevilla Resumen Y Resultado De La Fecha 35 De La Liga

May 14, 2025 -

Eurovision 2025 Final Dates For The Grand Final And Semi Finals

May 14, 2025

Eurovision 2025 Final Dates For The Grand Final And Semi Finals

May 14, 2025

Latest Posts

-

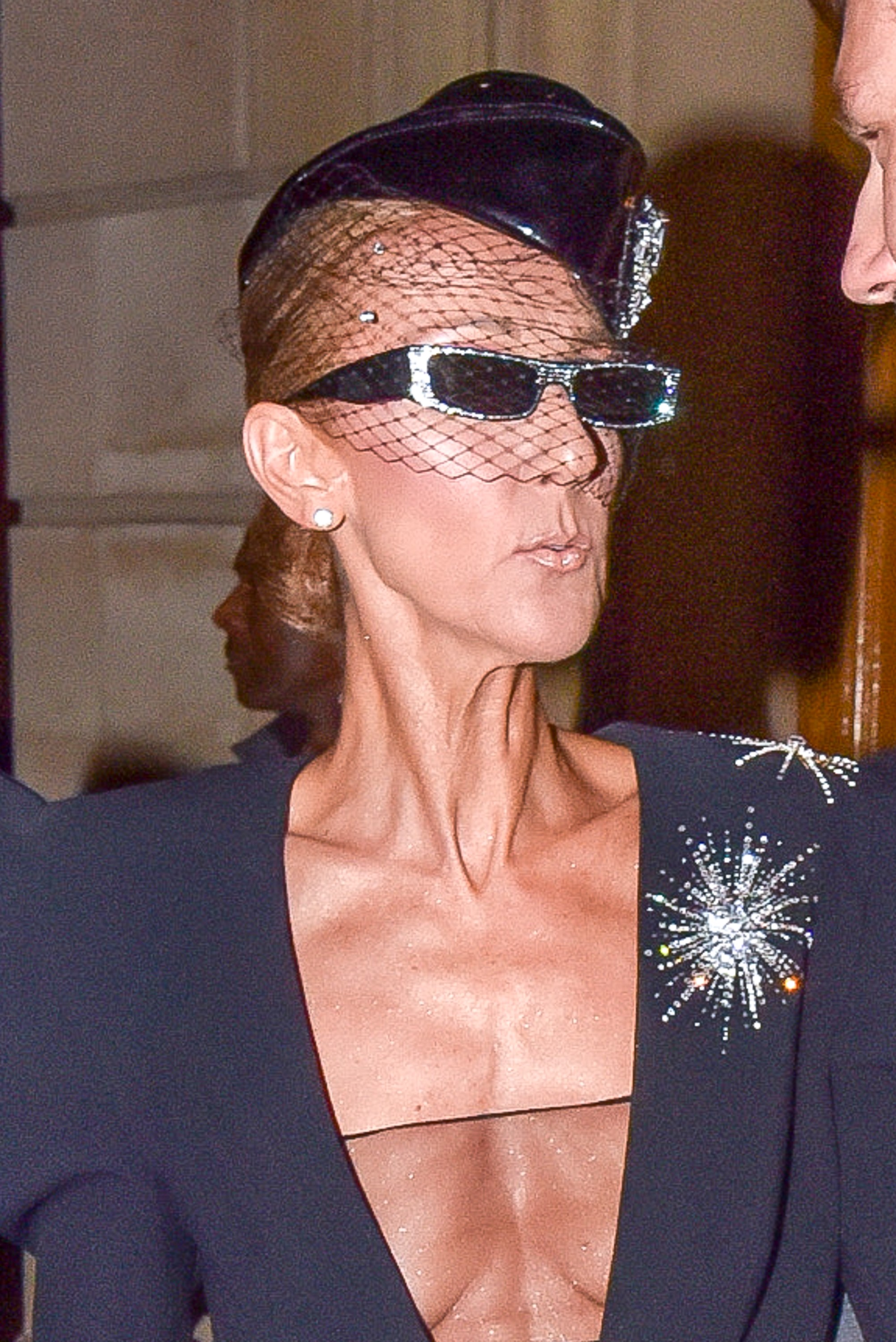

Zvicra Gatit Surprizen Celine Dion Ne Eurovizion 2025

May 14, 2025

Zvicra Gatit Surprizen Celine Dion Ne Eurovizion 2025

May 14, 2025 -

Eurovizioni 2025 Spekulime Per Pjesemarrjen E Celine Dion Me Zvicren

May 14, 2025

Eurovizioni 2025 Spekulime Per Pjesemarrjen E Celine Dion Me Zvicren

May 14, 2025 -

Eurovizijos Atidarymo Ceremonija Muzikos Protestu Ir Saunu Savaites Programos Pradzia Bazelyje

May 14, 2025

Eurovizijos Atidarymo Ceremonija Muzikos Protestu Ir Saunu Savaites Programos Pradzia Bazelyje

May 14, 2025 -

A Vjen Celine Dion Ne Eurovizion 2025 Per Zvicren

May 14, 2025

A Vjen Celine Dion Ne Eurovizion 2025 Per Zvicren

May 14, 2025 -

Is Celine Dion Returning To Eurovision After 37 Years

May 14, 2025

Is Celine Dion Returning To Eurovision After 37 Years

May 14, 2025