Securing Electric Motor Supplies: Alternatives To Chinese Manufacturing

Table of Contents

Evaluating the Risks of Solely Relying on Chinese Electric Motor Manufacturers

Over-dependence on a single source, especially in a complex global market like electric motor manufacturing, presents considerable risks. Let's examine the key vulnerabilities:

Supply Chain Disruptions

Unexpected events, such as the COVID-19 pandemic or natural disasters, can severely impact global supply chains. A heavy reliance on Chinese manufacturers for electric motors leaves businesses exposed to:

- Increased lead times: Delays in receiving essential components can halt production lines.

- Production delays: Factory closures due to unforeseen circumstances can significantly disrupt operations.

- Price volatility: Supply shortages drive up prices, impacting profitability.

- Potential for stockouts: Inability to obtain necessary electric motors can lead to production halts and lost revenue.

For instance, the pandemic exposed the fragility of global supply chains, with many businesses experiencing significant delays in receiving electric motor imports from China. This disruption highlighted the urgent need for diversification.

Geopolitical Risks and Trade Wars

The complex relationship between nations significantly influences international trade. Sourcing electric motors solely from China exposes businesses to:

- Increased import costs: Tariffs and trade restrictions imposed by governments can dramatically increase the cost of imported electric motors.

- Potential for trade sanctions: Geopolitical tensions can lead to sanctions, restricting or halting imports entirely.

- Political instability affecting production: Unrest or policy changes within China can directly impact manufacturing and delivery.

The ongoing US-China trade war serves as a stark example. Tariffs on electric motor components significantly increased costs for many businesses, emphasizing the need for alternative sourcing strategies.

Intellectual Property Concerns

Protecting intellectual property (IP) is crucial for maintaining a competitive edge. Sourcing electric motors from certain regions presents risks:

- Loss of competitive advantage: IP theft can allow competitors to replicate designs and technologies, undermining your market position.

- Potential for counterfeiting: Counterfeit electric motors compromise quality and safety, harming your brand reputation.

- Damage to brand reputation: Association with counterfeit products can severely damage consumer trust and brand loyalty.

Robust IP protection strategies, such as strong non-disclosure agreements (NDAs) and rigorous quality control measures, are essential when outsourcing electric motor production.

Exploring Alternative Sourcing Regions for Electric Motors

Diversifying your sourcing strategy is crucial for mitigating the risks associated with relying solely on Chinese manufacturers. Several alternative regions offer promising opportunities:

North American Manufacturers

Sourcing electric motors from the US, Canada, and Mexico presents several advantages:

- Shorter lead times: Reduced shipping distances translate to faster delivery times.

- Reduced transportation costs: Lower freight expenses improve profitability.

- Stronger intellectual property protection: Robust legal frameworks offer better IP safeguards.

- Higher labor costs: This is a potential disadvantage, but often balanced by other benefits.

Companies like Baldor Electric Company (US) and WEG Motors (Brazil, with significant North American presence) represent examples of reputable North American electric motor manufacturers.

European Electric Motor Suppliers

Europe boasts a strong manufacturing base, offering several compelling benefits:

- High-quality standards: European manufacturers adhere to stringent quality control and safety regulations.

- Advanced technology: Europe is a hub for innovation in electric motor technology.

- Strong regulatory frameworks: Robust legal and regulatory structures provide a stable business environment.

- Potentially higher costs: Labor and manufacturing costs can be higher compared to some other regions.

Siemens, ABB, and Bosch Rexroth are just a few examples of the many prominent European electric motor suppliers.

Southeast Asian Alternatives

Countries like Vietnam, Thailand, and Malaysia are emerging as attractive alternatives:

- Lower labor costs: These regions offer significantly lower labor costs compared to North America or Europe.

- Growing manufacturing capabilities: Manufacturing infrastructure and expertise are rapidly developing.

- Proximity to other Asian markets: Strategic location simplifies access to other Asian markets.

- Potential for infrastructure limitations: Infrastructure development may lag behind more established manufacturing hubs.

Careful due diligence is crucial when selecting a manufacturer in Southeast Asia, considering both potential benefits and limitations.

Strategies for Diversifying Electric Motor Supply Chains

Implementing strategic diversification measures strengthens your resilience against supply chain disruptions:

Dual Sourcing

Working with multiple suppliers is a cornerstone of risk mitigation:

- Reduced risk of disruptions: If one supplier experiences issues, the other can compensate.

- Increased bargaining power: Competition between suppliers can lead to better pricing and terms.

- Improved quality control: Having multiple suppliers provides a broader range of quality control checks.

A balanced approach, carefully selecting two or more reliable suppliers with different geographical locations and production capabilities is key.

Nearshoring and Reshoring

Bringing production closer to home or back to the home country offers several advantages:

- Improved control over the supply chain: Greater visibility and control over the entire production process.

- Reduced transportation costs: Shorter shipping distances significantly reduce logistics expenses.

- Enhanced responsiveness: Faster reaction to market demands and changes.

A thorough cost-benefit analysis is essential before deciding on nearshoring or reshoring, considering the impact on labor costs and overall expenses.

Building Strategic Partnerships

Cultivating strong relationships with suppliers is paramount:

- Improved communication and collaboration: Open communication facilitates efficient problem-solving and collaboration.

- Access to better pricing and terms: Strong relationships often lead to preferential pricing and favorable contract terms.

- Increased loyalty and commitment: Loyal suppliers are more likely to prioritize your needs in challenging times.

Regular communication, mutual trust, and a commitment to long-term collaboration are essential for building effective supplier partnerships.

Conclusion

Securing a reliable supply of electric motors is crucial for businesses across various sectors. Over-reliance on Chinese manufacturing presents significant risks that can severely impact operations. By exploring alternative sourcing regions, diversifying supply chains, and building strong supplier relationships, companies can mitigate these risks and ensure business continuity. Don't wait until a crisis hits—actively explore your options for securing electric motor supplies today and build a more resilient and robust supply chain. Start diversifying your sourcing strategy for securing electric motor supplies now, and protect your business's future.

Featured Posts

-

The Australian Election A Key Indicator Of Global Anti Trump Trends

May 05, 2025

The Australian Election A Key Indicator Of Global Anti Trump Trends

May 05, 2025 -

Chicago Med Season 10 Episode 14 Dr Ethan Chois Comeback

May 05, 2025

Chicago Med Season 10 Episode 14 Dr Ethan Chois Comeback

May 05, 2025 -

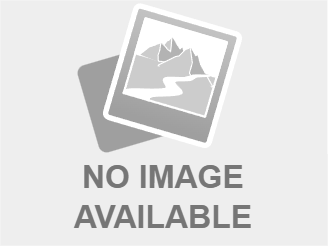

West Bengal Weather Latest Updates And Rainfall Predictions For North Bengal

May 05, 2025

West Bengal Weather Latest Updates And Rainfall Predictions For North Bengal

May 05, 2025 -

High Profile Office365 Hack Leads To Multi Million Dollar Theft

May 05, 2025

High Profile Office365 Hack Leads To Multi Million Dollar Theft

May 05, 2025 -

Ufc 314 Co Main Event Prediction Analyzing Chandler Vs Pimblett

May 05, 2025

Ufc 314 Co Main Event Prediction Analyzing Chandler Vs Pimblett

May 05, 2025

Latest Posts

-

Torture Death Of 16 Year Old Leads To Mothers Criminal Neglect Arrest

May 05, 2025

Torture Death Of 16 Year Old Leads To Mothers Criminal Neglect Arrest

May 05, 2025 -

Stepsons Death Stepfather Faces Murder Charges Following Alleged Abuse

May 05, 2025

Stepsons Death Stepfather Faces Murder Charges Following Alleged Abuse

May 05, 2025 -

Criminal Neglect Charges Filed Against Mother In Teens Torture Death

May 05, 2025

Criminal Neglect Charges Filed Against Mother In Teens Torture Death

May 05, 2025 -

Chicago Med Season 10 Episode 14 Dr Ethan Chois Comeback

May 05, 2025

Chicago Med Season 10 Episode 14 Dr Ethan Chois Comeback

May 05, 2025 -

Raiwaqa Fire Claims Womans Life

May 05, 2025

Raiwaqa Fire Claims Womans Life

May 05, 2025