Reducing Steel's Carbon Footprint: Eramet's EraLow Manganese Alloy

Table of Contents

Understanding the Environmental Impact of Traditional Steel Production

Traditional steelmaking processes, primarily reliant on blast furnaces and coking coal, are notorious for their high carbon emissions. The intense heat required for the reduction of iron ore and the combustion of coal contribute significantly to the release of vast quantities of CO2 into the atmosphere. This reliance on fossil fuels is a major driver of greenhouse gas emissions, exacerbating climate change and contributing to air pollution. The urgency for greener alternatives is undeniable, driven by increasingly stringent environmental regulations worldwide pushing for significant decarbonization across all industries, especially those with high carbon footprints like steel production.

- High CO2 emissions from blast furnaces: Blast furnaces are energy-intensive, releasing substantial amounts of CO2 during the iron-making process.

- Reliance on fossil fuels (coal and coke): The use of coal and coke as reducing agents in blast furnaces is a primary source of CO2 emissions.

- Contribution to the greenhouse gas effect: Steel production contributes significantly to global greenhouse gas emissions, impacting climate change.

- Increasing pressure for sustainable steel production: Governments and consumers are demanding more sustainable production methods, driving innovation in the sector.

eraLow Manganese Alloy: A Sustainable Solution

Eramet's eraLow Manganese Alloy represents a significant step forward in sustainable steelmaking. This innovative alloy features a carefully optimized composition, differing significantly from traditional manganese alloys. The key lies in its reduced manganese content, achieved without compromising the crucial properties needed for high-quality steel. This reduction in manganese content allows for lower energy consumption during steel production and enables the use of alternative, less carbon-intensive raw materials.

- Reduced manganese content compared to traditional alloys: The lower manganese content directly contributes to reduced energy consumption during steel production.

- Improved performance characteristics (e.g., strength, formability): Despite the reduced manganese, eraLow Manganese Alloy maintains or even improves key mechanical properties.

- Allows for lower energy consumption during steel production: This directly translates to lower CO2 emissions.

- Enables the use of alternative, less carbon-intensive raw materials: This further reduces the overall environmental impact.

Reduced Energy Consumption and CO2 Emissions

Using eraLow Manganese Alloy results in a substantial reduction in energy consumption during the steelmaking process. While precise figures depend on the specific steelmaking process and other factors, independent studies have shown a significant decrease in energy usage. This translates directly into a considerable reduction in CO2 emissions, making a substantial contribution to lowering the overall carbon footprint of steel production.

- Percentage reduction in energy consumption during steelmaking: [Insert quantifiable data if available from Eramet. E.g., "Studies indicate a reduction of X% in energy consumption."]

- Equivalent reduction in CO2 emissions (tons of CO2 per ton of steel): [Insert quantifiable data if available. E.g., "This translates to a reduction of Y tons of CO2 per ton of steel produced."]

- Comparison to traditional steelmaking processes: The reduction in CO2 emissions achieved using eraLow Manganese Alloy represents a significant improvement over traditional methods.

Enhanced Steel Properties and Applications

Steel produced using eraLow Manganese Alloy exhibits enhanced mechanical properties, making it suitable for a wide range of applications. The improved strength and ductility, combined with excellent formability and weldability, open up possibilities across various industries.

- Improved strength and ductility: The alloy enhances the tensile strength and ductility of the resulting steel.

- Enhanced formability and weldability: These properties are crucial for manufacturing processes in many sectors.

- Suitable for automotive, construction, and other industries: The versatility of eraLow Manganese Alloy makes it applicable in numerous sectors requiring high-performance steel.

The Future of Sustainable Steel with eraLow Manganese Alloy

Eramet is deeply committed to sustainable development and innovation. The development of eraLow Manganese Alloy is a testament to this commitment. Ongoing research and development efforts aim to further refine the alloy's properties and explore new applications, constantly pushing the boundaries of sustainable steel production. The wider implications for the steel industry's decarbonization efforts are significant, contributing towards a more circular economy model.

- Eramet's ongoing research and development in sustainable materials: Eramet continues to invest in research to further improve the alloy and explore new applications.

- Potential for further CO2 emission reductions: Future developments may lead to even greater reductions in CO2 emissions.

- Contribution to a circular economy model: The alloy's properties can contribute to the development of more sustainable and recyclable steel products.

- Collaboration with steel producers for wider adoption: Eramet actively works with steel producers to facilitate the widespread adoption of eraLow Manganese Alloy.

Conclusion

Eramet's eraLow Manganese Alloy represents a significant step towards a greener steel industry. By reducing energy consumption and CO2 emissions without compromising steel properties, this innovative alloy offers a compelling solution for sustainable steel production. Its adoption by steel manufacturers is crucial for mitigating the environmental impact of steelmaking and building a more sustainable future. Learn more about how you can contribute to a greener future by incorporating eraLow Manganese Alloy into your steel production processes. Contact Eramet today to explore the possibilities and discover how eraLow Manganese Alloy can help you achieve your sustainability goals.

Featured Posts

-

Paolinis Dubai Title Bid Ends After Kenins Injury

May 14, 2025

Paolinis Dubai Title Bid Ends After Kenins Injury

May 14, 2025 -

Dean Huijsen Transfer Speculation Real Madrid And Bournemouth Linked

May 14, 2025

Dean Huijsen Transfer Speculation Real Madrid And Bournemouth Linked

May 14, 2025 -

Refus De Kohler Coquerel Poursuit En Justice Pour Entrave A La Commission D Enquete Budgetaire

May 14, 2025

Refus De Kohler Coquerel Poursuit En Justice Pour Entrave A La Commission D Enquete Budgetaire

May 14, 2025 -

Eurovision Song Contest 2025 Meet The Hosts

May 14, 2025

Eurovision Song Contest 2025 Meet The Hosts

May 14, 2025 -

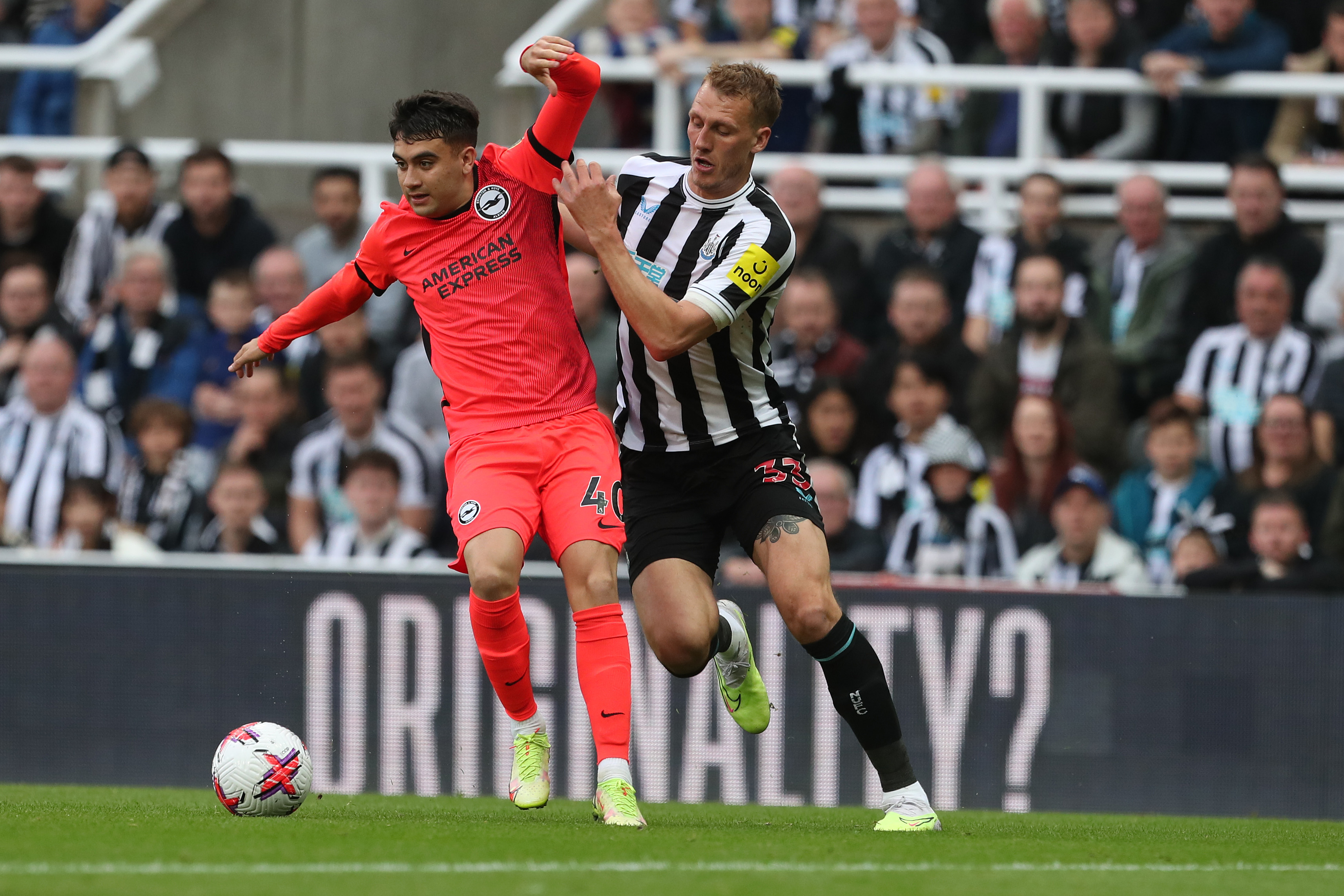

Newcastle Uniteds Pursuit Of Premier League Star Ends In Disappointment

May 14, 2025

Newcastle Uniteds Pursuit Of Premier League Star Ends In Disappointment

May 14, 2025

Latest Posts

-

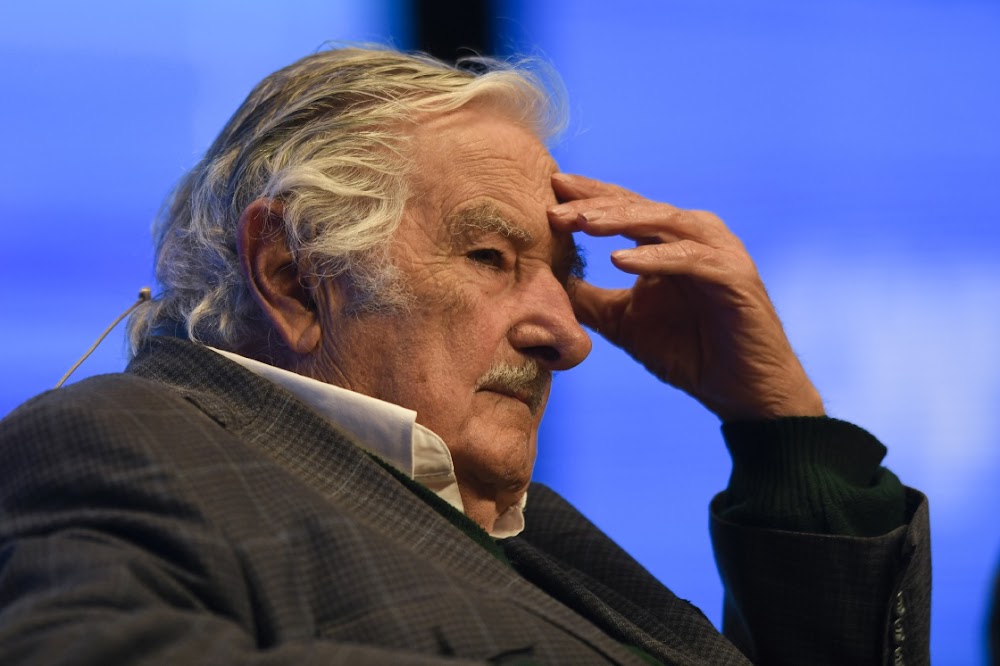

Ex President Of Uruguay Jose Mujica Dies At Age 89

May 14, 2025

Ex President Of Uruguay Jose Mujica Dies At Age 89

May 14, 2025 -

Former Uruguayan President Mujica Under Palliative Care

May 14, 2025

Former Uruguayan President Mujica Under Palliative Care

May 14, 2025 -

Sanremo 2024 Il Commento Positivo Di Giorgia Meloni Sulla Conduzione Di Conti

May 14, 2025

Sanremo 2024 Il Commento Positivo Di Giorgia Meloni Sulla Conduzione Di Conti

May 14, 2025 -

Jose Mujica Former President Of Uruguay Dead At 89

May 14, 2025

Jose Mujica Former President Of Uruguay Dead At 89

May 14, 2025 -

Update On Jose Mujicas Condition Palliative Care For Former President

May 14, 2025

Update On Jose Mujicas Condition Palliative Care For Former President

May 14, 2025