Promoting "Made In Pakistan": Ahsan's Plea For Technological Integration

Table of Contents

The Current State of "Made in Pakistan"

Challenges Facing Pakistani Manufacturers

Pakistani manufacturers face a multitude of hurdles that hinder their competitiveness. These include outdated technology, a shortage of skilled labor, inadequate infrastructure, and limited access to finance. The "Made in Pakistan" label, while representing potential, currently lacks the global recognition enjoyed by brands from other nations.

- Textile Industry: Outdated machinery leads to lower productivity and higher production costs compared to global competitors. Lack of access to advanced textile technologies limits the production of high-value fabrics.

- Leather Goods: Inefficient tanning processes contribute to environmental concerns and limit the ability to produce high-quality, sustainable leather products. Limited access to design software and marketing expertise further hampers international competitiveness.

- Food Processing: Poor infrastructure and inadequate cold storage facilities lead to significant post-harvest losses, impacting the quality and shelf life of "Made in Pakistan" food products. Lack of automation in packaging and processing reduces efficiency.

These challenges significantly affect the ability to promote "Pakistan-made products" internationally and build a robust "Made in Pakistan" brand. Promoting Pakistani goods requires addressing these systemic issues.

The Need for Brand Revitalization

The "Made in Pakistan" brand needs a significant revitalization to compete effectively in the global market. A stronger brand identity is essential to attract international buyers and consumers.

- Targeted Marketing Campaigns: Invest in strategic marketing campaigns that highlight the quality, craftsmanship, and unique aspects of "Made in Pakistan" products. Showcase the rich heritage and cultural significance of Pakistani goods.

- Stringent Quality Control Measures: Implement rigorous quality control measures throughout the production process to ensure consistent product quality and build consumer trust. Certifications and standards can significantly improve the reputation of "Made in Pakistan" goods.

- Modern Packaging and Branding: Invest in attractive and informative packaging that reflects the quality and sophistication of the products. Modern branding strategies are crucial for attracting a global audience. Strengthening Pakistan's export image requires a multi-pronged approach focusing on quality, branding, and marketing.

Technological Integration as a Solution

Embracing Automation and Technology

Adopting advanced technologies like automation, Artificial Intelligence (AI), and data analytics is vital for improving efficiency and productivity in Pakistani industries. This is paramount for promoting "Made in Pakistan" technology globally.

- Automation in Manufacturing: Investing in automated machinery can reduce production costs, improve quality, and enhance overall efficiency. This will allow Pakistani manufacturers to compete on price and quality with international players.

- AI-Powered Quality Control: AI-powered systems can monitor and improve quality control processes, reducing defects and enhancing product consistency.

- Data Analytics for Supply Chain Optimization: Using data analytics to optimize supply chains can minimize waste, improve delivery times, and reduce overall costs. This will lead to greater competitiveness in the global market. Successful technology adoption in countries like Bangladesh and Vietnam provides valuable lessons for Pakistan.

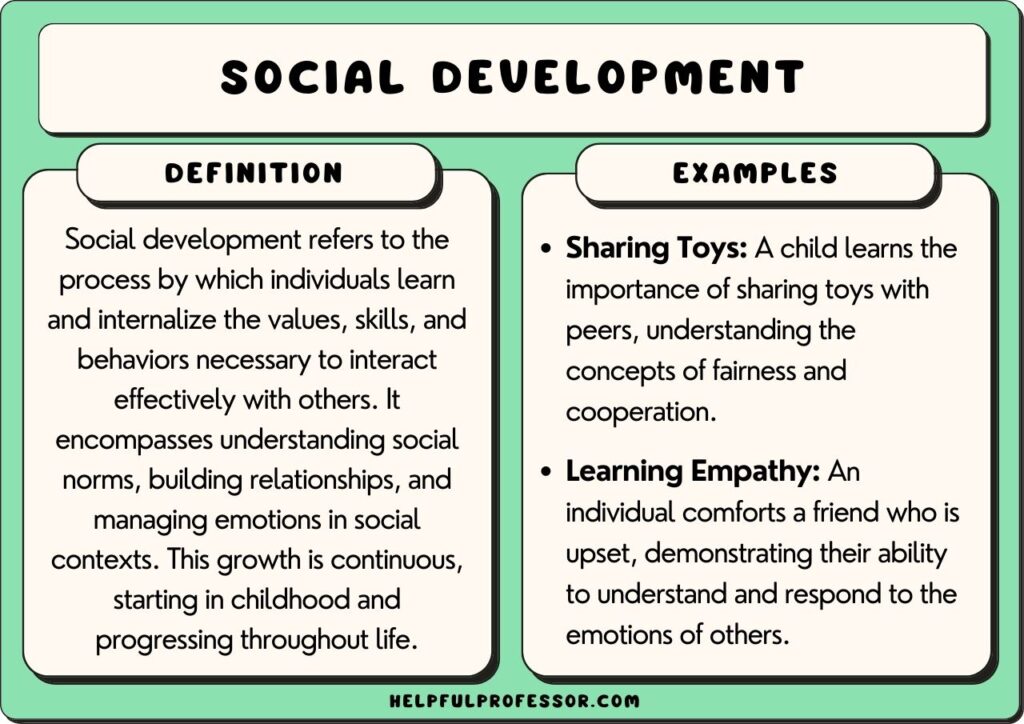

Investing in Skilled Workforce Development

Technological advancement demands a skilled workforce. Investing in training and education is crucial to bridge the technological skills gap in Pakistan.

- Technical Training Programs: Implement comprehensive technical training programs focusing on the operation and maintenance of advanced technologies. Collaborate with vocational schools and universities to develop relevant curricula.

- Industry-Academia Partnerships: Foster collaborations between industries and educational institutions to ensure that training programs align with the needs of the manufacturing sector.

- International Collaboration: Seek partnerships with international organizations and institutions to access expertise and resources in workforce development. The skilled workforce for "Made in Pakistan" is essential for sustained growth.

Improving Infrastructure and Supply Chains

Reliable infrastructure is a cornerstone of technological integration. Significant improvements are needed in electricity, transportation, and communication networks.

- Reliable Power Supply: Invest in reliable power generation and distribution infrastructure to ensure uninterrupted production.

- Efficient Transportation Networks: Develop efficient and affordable transportation networks to facilitate the movement of goods and materials.

- High-Speed Internet Connectivity: Expand access to high-speed internet connectivity to support the adoption of digital technologies and enhance communication. Infrastructure development for "Made in Pakistan" is crucial for boosting the competitiveness of local industries.

Government Support and Policy Recommendations

Policy Initiatives to Foster Technological Adoption

Government policies play a pivotal role in incentivizing technology adoption. Targeted interventions are necessary to support Pakistani manufacturers.

- Tax Breaks and Subsidies: Offer tax breaks and subsidies for businesses that invest in advanced technologies.

- Investment in R&D: Increase government investment in research and development to support the development and application of new technologies.

- Streamlined Regulations: Simplify regulations and procedures related to technology imports and investment to attract foreign investment in technology transfer. Government support for "Made in Pakistan" requires clear and supportive policies.

Public-Private Partnerships

Collaboration between the government and the private sector is essential to accelerate technological advancement.

- Joint Ventures: Encourage joint ventures between local businesses and international technology providers to facilitate technology transfer and knowledge sharing.

- Incubation Centers: Establish technology incubation centers to support the growth of innovative technology startups.

- Investment Funds: Create dedicated investment funds to support the development and adoption of new technologies in the manufacturing sector. Public-private partnerships for "Made in Pakistan" are vital for achieving rapid progress.

Conclusion

The challenges facing "Made in Pakistan" are significant, but not insurmountable. Ahsan's plea for technological integration is a pragmatic and essential pathway towards revitalizing the "Made in Pakistan" brand. By embracing automation, investing in skilled workforce development, improving infrastructure, and implementing supportive government policies, Pakistan can unlock its vast manufacturing potential. The future of "Made in Pakistan" hinges on collaboration between the government, the private sector, and individuals. Let's work together to support this vital initiative. Visit [website address] to learn more about supporting "Made in Pakistan" and join the conversation on social media using #MadeInPakistan.

Featured Posts

-

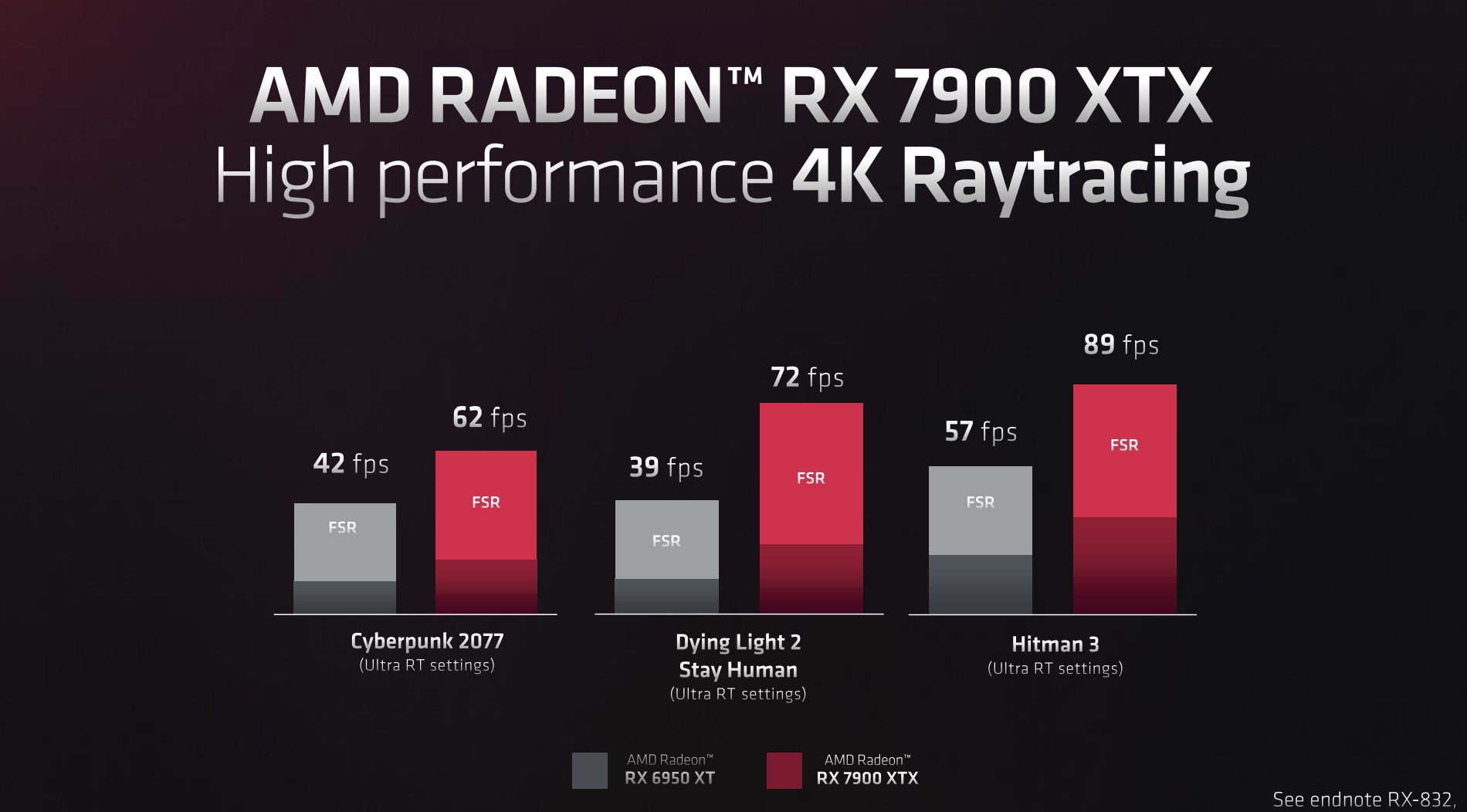

Improved Assassins Creed Shadows Graphics On Ps 5 Pro Ray Tracing Performance

May 08, 2025

Improved Assassins Creed Shadows Graphics On Ps 5 Pro Ray Tracing Performance

May 08, 2025 -

Andor Season 2 The Trailers Absence Sparks Intense Fan Debate

May 08, 2025

Andor Season 2 The Trailers Absence Sparks Intense Fan Debate

May 08, 2025 -

Uber Kenya Improves Earnings For Drivers And Couriers While Offering Customers Cashback

May 08, 2025

Uber Kenya Improves Earnings For Drivers And Couriers While Offering Customers Cashback

May 08, 2025 -

Isabt Barbwza Fy Marakana Tfasyl Fqdan Alasnan

May 08, 2025

Isabt Barbwza Fy Marakana Tfasyl Fqdan Alasnan

May 08, 2025 -

Kontraktnoe Predlozhenie Zenita Zhersonu Summa I Detali Ot Zhurnalista

May 08, 2025

Kontraktnoe Predlozhenie Zenita Zhersonu Summa I Detali Ot Zhurnalista

May 08, 2025

Latest Posts

-

Xu Ly Nghiem Ngat Vu Bao Mau Tat Tre O Tien Giang Tuong Lai An Toan Cho Tre Em

May 09, 2025

Xu Ly Nghiem Ngat Vu Bao Mau Tat Tre O Tien Giang Tuong Lai An Toan Cho Tre Em

May 09, 2025 -

The Delicate Years Daycare Decisions And Your Childs Development

May 09, 2025

The Delicate Years Daycare Decisions And Your Childs Development

May 09, 2025 -

Should You Delay Daycare Expert Weighs In On Infant Vulnerability

May 09, 2025

Should You Delay Daycare Expert Weighs In On Infant Vulnerability

May 09, 2025 -

So Very Fragile A Parenting Expert Explains The Risks Of Early Daycare

May 09, 2025

So Very Fragile A Parenting Expert Explains The Risks Of Early Daycare

May 09, 2025 -

Child Rapist Living Near Massachusetts Daycare Investigation Underway

May 09, 2025

Child Rapist Living Near Massachusetts Daycare Investigation Underway

May 09, 2025