Low-CO2 Manganese Alloys: Eramet's EraLow And The Future Of Steel Production

Table of Contents

Understanding the Environmental Impact of Traditional Steel Production

Steel production is a major source of global greenhouse gas emissions, contributing substantially to climate change. Traditional steelmaking processes, reliant on high-carbon sources like coal for energy and iron ore reduction, generate substantial amounts of carbon dioxide (CO2). The environmental impact of this process extends beyond CO2 emissions, encompassing air and water pollution and the depletion of natural resources. The urgency to decarbonize the steel sector cannot be overstated, necessitating a fundamental shift towards sustainable practices.

- Significant CO2 Emissions: Steel production accounts for approximately 7-9% of global CO2 emissions.

- Traditional Process: The blast furnace process, a cornerstone of traditional steelmaking, relies on coke (derived from coal) for iron ore reduction, leading to substantial CO2 emissions.

- The Urgency for Change: Meeting global climate targets necessitates drastic reductions in the steel industry's carbon emissions. This requires innovative solutions and a comprehensive approach.

Eramet's eraLow: A Game Changer in Low-CO2 Manganese Alloys

Eramet's eraLow represents a significant leap forward in sustainable steel production. This innovative range of low-CO2 manganese alloys utilizes a proprietary technology that drastically reduces greenhouse gas emissions compared to traditional manganese alloy production methods. eraLow alloys maintain superior properties and performance, ensuring they are a viable and effective replacement for conventional options. This technology contributes directly to the production of green steel.

- Innovative Production: eraLow alloys are produced using a process that minimizes CO2 emissions throughout the production chain.

- Significant Emission Reduction: Eramet's technology achieves a significant percentage reduction in CO2 emissions compared to traditional methods, offering a clear pathway to decarbonization.

- Superior Properties: eraLow alloys offer comparable, if not superior, performance characteristics to conventional manganese alloys, ensuring seamless integration into existing steelmaking processes. Specific applications include high-strength low-alloy (HSLA) steels and other advanced steel grades.

The Benefits of Using Low-CO2 Manganese Alloys in Steel Production

Incorporating eraLow alloys into steel production offers a multitude of benefits beyond reduced carbon emissions. These benefits extend across environmental, economic, and social spheres, strengthening the steel industry's sustainability profile.

- Reduced Carbon Footprint: The use of eraLow alloys directly contributes to a lower overall carbon footprint for each ton of steel produced, helping steel manufacturers meet their sustainability goals.

- Economic Advantages: While initial investment may be required, the long-term economic advantages of using sustainable materials and processes can lead to cost savings and increased competitiveness.

- Enhanced Industry Image: Adopting sustainable practices like using eraLow enhances the steel industry’s image and strengthens its position in a increasingly environmentally conscious market, making it more attractive to environmentally conscious clients.

The Future of Steel Production: Towards a Greener and More Sustainable Industry

Low-CO2 manganese alloys, like Eramet's eraLow, are pivotal in shaping the future of steel production. Their widespread adoption will contribute significantly to reducing the industry's environmental impact and pave the way for a truly green steel sector.

- Future Emission Reductions: Widespread adoption of low-CO2 manganese alloys could lead to substantial reductions in CO2 emissions across the steel industry in the coming decades.

- Technological Advancements: Further innovation and collaboration across the industry are expected to yield even more sustainable steelmaking processes, complementing the use of low-CO2 manganese alloys.

- Collaborative Approach: Achieving a truly sustainable steel industry requires a collaborative effort between industry stakeholders, researchers, and policymakers to drive innovation, implement policy changes, and support the transition to a greener future.

Conclusion

Eramet's eraLow represents a significant step towards a more sustainable future for the steel industry. The substantial reduction in CO2 emissions achievable through the adoption of low-CO2 manganese alloys is undeniable. This, coupled with economic and environmental advantages, makes eraLow a game-changer. The future of steel production hinges on embracing such innovative solutions and actively participating in the transition to a greener and more sustainable industry. Discover the advantages of low-CO2 manganese alloys and embrace the future of sustainable steel production with Eramet's eraLow – visit [link to Eramet's website].

Featured Posts

-

Manchester Uniteds Pursuit Of Championship Talent Transfer Fee And Competition

May 14, 2025

Manchester Uniteds Pursuit Of Championship Talent Transfer Fee And Competition

May 14, 2025 -

Confirmation Maya Jama Dating Ruben Dias

May 14, 2025

Confirmation Maya Jama Dating Ruben Dias

May 14, 2025 -

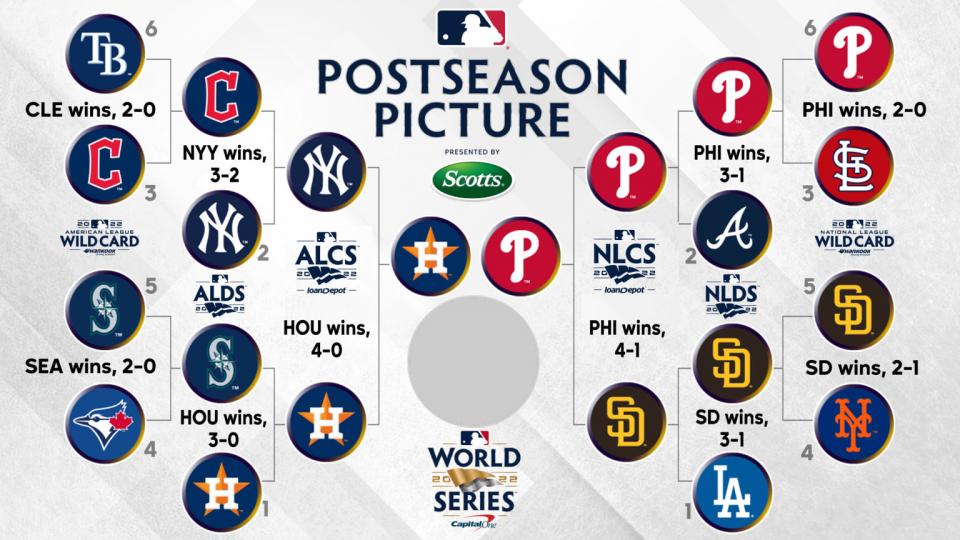

Mlb 2025 Playoffs A Path To Postseason For Every Team Including The Rockies And White Sox

May 14, 2025

Mlb 2025 Playoffs A Path To Postseason For Every Team Including The Rockies And White Sox

May 14, 2025 -

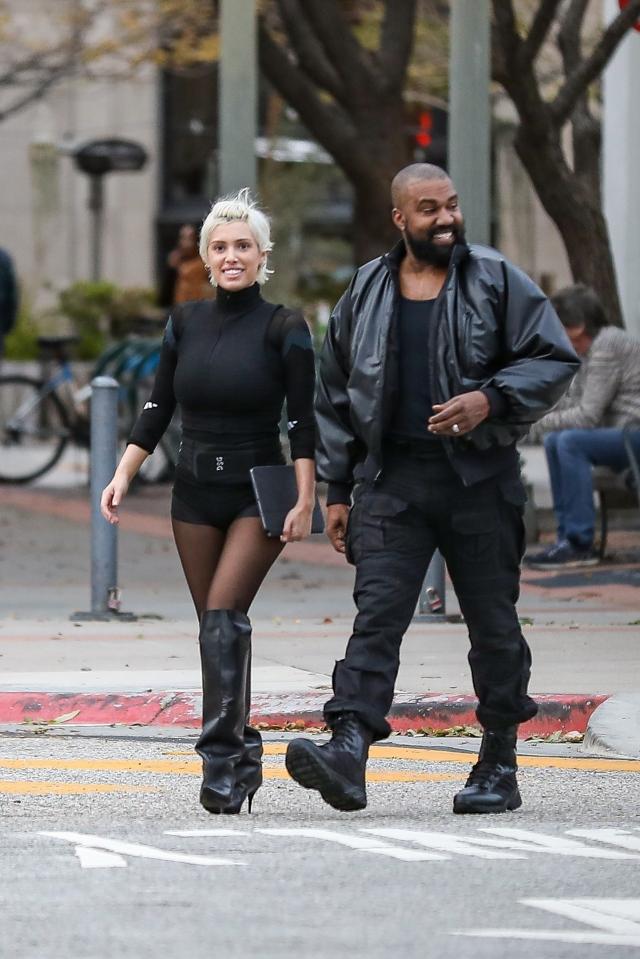

Kanye West Bianca Censoris Spanish Dinner Date Amidst Relationship Speculation

May 14, 2025

Kanye West Bianca Censoris Spanish Dinner Date Amidst Relationship Speculation

May 14, 2025 -

Enoteca Maria Nonnas Legacy And The Staten Island Culinary Gem

May 14, 2025

Enoteca Maria Nonnas Legacy And The Staten Island Culinary Gem

May 14, 2025

Latest Posts

-

Sanremo Il Concerto Musica E Pace Raccoglie Fondi Per Al Fa Pp

May 14, 2025

Sanremo Il Concerto Musica E Pace Raccoglie Fondi Per Al Fa Pp

May 14, 2025 -

Concerto Di Beneficenza A Sanremo Musica E Pace Sostiene I Pazienti Psichiatrici

May 14, 2025

Concerto Di Beneficenza A Sanremo Musica E Pace Sostiene I Pazienti Psichiatrici

May 14, 2025 -

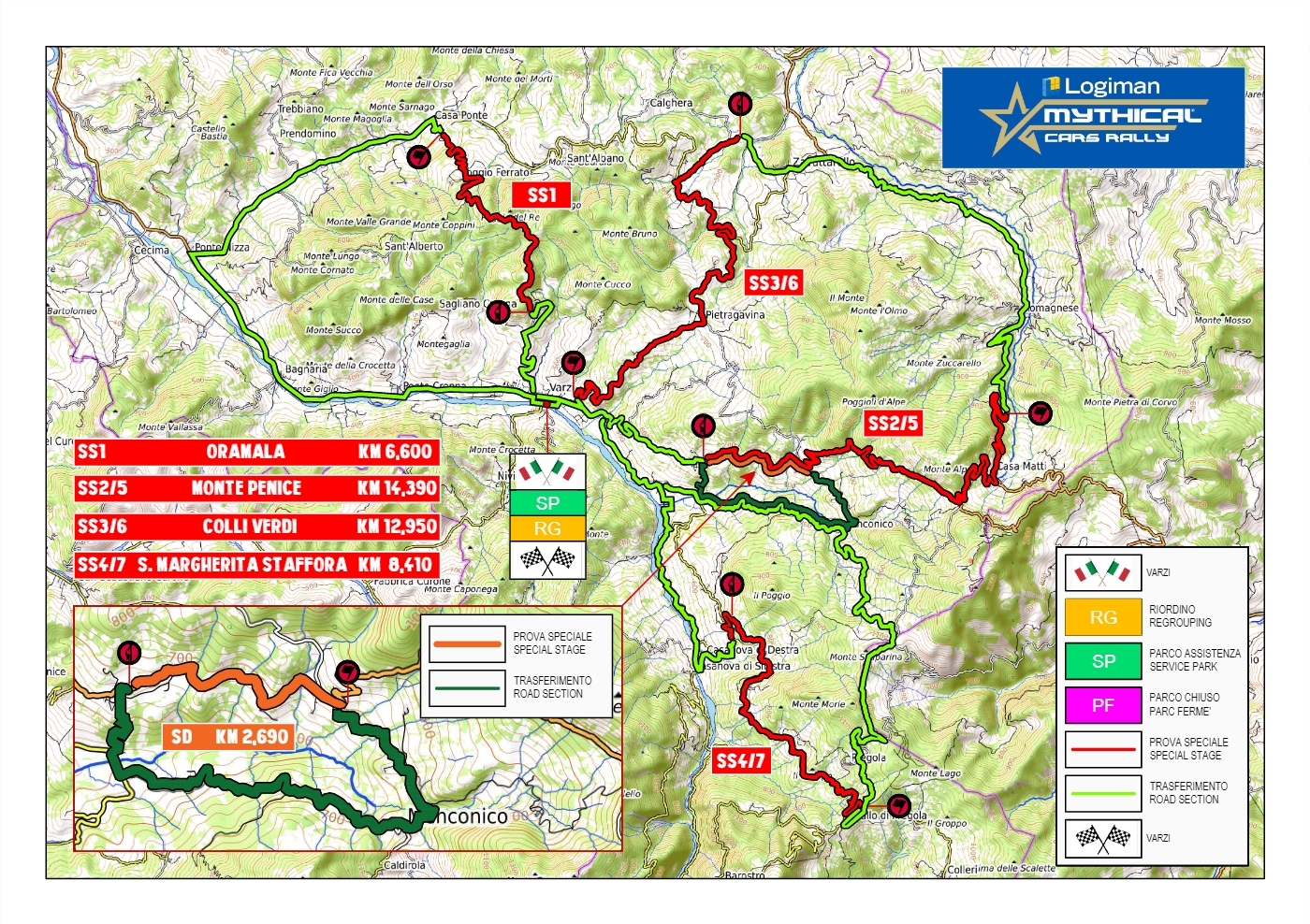

Aggiornamenti Strade Chiuse Percorso Milano Sanremo 2025 In Lombardia

May 14, 2025

Aggiornamenti Strade Chiuse Percorso Milano Sanremo 2025 In Lombardia

May 14, 2025 -

Sanremo 720 Euro Raccolti Per I Pazienti Psichiatrici Al Concerto Musica E Pace

May 14, 2025

Sanremo 720 Euro Raccolti Per I Pazienti Psichiatrici Al Concerto Musica E Pace

May 14, 2025 -

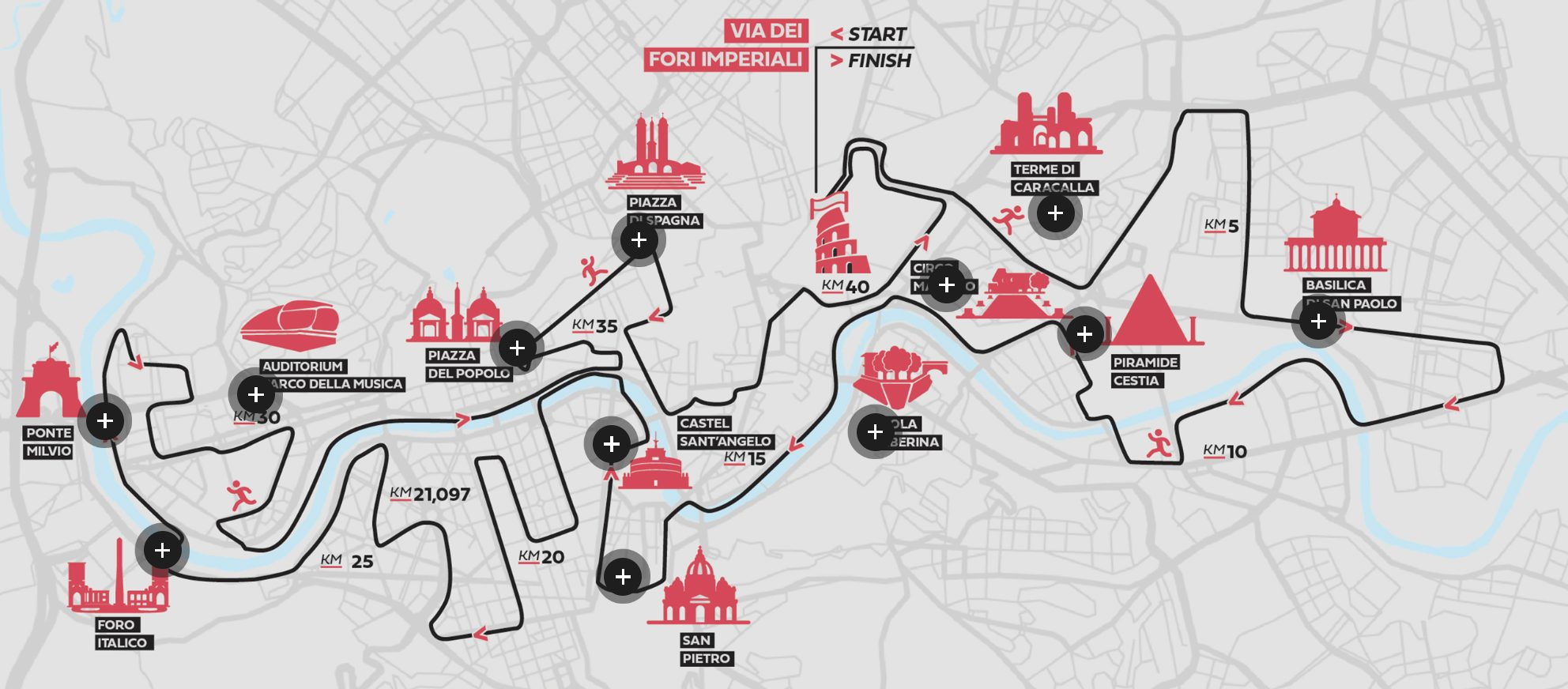

Milano Sanremo 2025 Mappa Del Percorso E Strade Interessate In Lombardia

May 14, 2025

Milano Sanremo 2025 Mappa Del Percorso E Strade Interessate In Lombardia

May 14, 2025