Key Factors Driving Growth In The Vaccine Packaging Market

Table of Contents

Rising Global Vaccination Rates and Immunization Programs

The increasing global demand for vaccines is a primary driver of market growth. Rising awareness of preventable diseases, coupled with proactive government initiatives, has significantly boosted vaccination rates worldwide. This increased demand necessitates robust and reliable vaccine packaging solutions capable of maintaining vaccine efficacy throughout the supply chain.

- Increased funding for immunization programs in developing countries: International organizations and governments are investing heavily in expanding vaccine access to underserved populations, fueling the need for cost-effective and reliable packaging.

- Expansion of national immunization schedules to include new vaccines: The continuous development of vaccines for a wider range of diseases, including newer preventative measures, means a broader requirement for specialized packaging solutions.

- Growing awareness of vaccine-preventable diseases among the public: Public health campaigns and educational initiatives have increased public understanding of the importance of vaccination, leading to higher demand.

- Government mandates and incentives for vaccination: Many countries implement mandatory vaccination programs or offer incentives, further driving the need for efficient vaccine packaging and distribution systems.

Technological Advancements in Vaccine Packaging Materials

Innovations in vaccine packaging materials are revolutionizing the industry, improving vaccine stability, safety, and transportation. These advancements are crucial for ensuring the efficacy of vaccines, especially those requiring stringent temperature control.

- Development of temperature-sensitive packaging solutions (cold chain packaging): Advanced cold chain packaging, including insulated containers, gel packs, and temperature data loggers, ensures vaccines remain within their required temperature range during transport and storage. This is crucial for maintaining vaccine potency.

- Use of sustainable and eco-friendly materials: The industry is increasingly adopting sustainable packaging materials, such as biodegradable polymers and recycled plastics, to minimize environmental impact. This is a growing area of concern for environmentally conscious consumers and regulators.

- Improved barrier properties to protect vaccines from environmental factors: New materials offer enhanced protection against moisture, oxygen, and light, preserving vaccine stability and extending shelf life. This is vital for maintaining product quality across diverse climates and transportation times.

- Integration of smart packaging technologies for real-time monitoring: Smart packaging incorporates sensors and data loggers that provide real-time tracking of temperature, humidity, and location, allowing for proactive management of the cold chain and early detection of potential issues.

Stringent Regulatory Requirements and Quality Control Measures

Stringent regulations and quality control measures play a significant role in shaping the vaccine packaging market. Compliance with international standards is paramount, driving the demand for specialized packaging that meets these rigorous requirements.

- Compliance with GMP (Good Manufacturing Practices) and other international standards: Manufacturers must adhere to stringent GMP guidelines and other international standards to ensure the safety and quality of their products, impacting the design and materials used for vaccine packaging.

- Increased scrutiny of vaccine packaging integrity and safety: Regulatory bodies are increasingly focused on ensuring the integrity and safety of vaccine packaging, demanding tamper-evident features and robust quality control measures.

- Demand for tamper-evident and trackable packaging: Tamper-evident packaging helps prevent counterfeiting and ensures product authenticity, while track-and-trace systems provide complete visibility into the vaccine supply chain, adding to the security and overall reliability of the supply chain.

- Rising importance of robust quality control systems: Manufacturers are implementing sophisticated quality control systems to monitor every stage of the packaging process, ensuring consistent quality and compliance with regulatory standards.

The Impact of the COVID-19 Pandemic

The COVID-19 pandemic dramatically accelerated the growth of the vaccine packaging market. The unprecedented demand for vaccines spurred massive investment in cold chain infrastructure and the development of specialized packaging solutions.

- Massive increase in vaccine production and distribution: The urgent need to vaccinate populations globally resulted in a massive increase in vaccine production and distribution, placing immense pressure on existing packaging infrastructure.

- Development of specialized packaging for COVID-19 vaccines (mRNA vaccines): mRNA vaccines, such as the Pfizer-BioNTech and Moderna vaccines, required specialized packaging to maintain their ultra-low temperature stability, driving innovation in cold chain packaging.

- Increased investment in cold chain infrastructure: The pandemic spurred significant investment in cold chain infrastructure, including specialized transport vehicles, storage facilities, and monitoring technologies.

Growing Demand for Pre-filled Syringes and Auto-injectors

The increasing preference for pre-filled syringes and auto-injectors is another key factor driving market growth. These delivery systems offer convenience, reduce waste, and improve safety compared to traditional vial-based systems.

- Enhanced accuracy and dosage control: Pre-filled syringes ensure accurate dosage administration, minimizing errors and improving vaccine efficacy.

- Reduced risk of needle stick injuries: Pre-filled syringes and auto-injectors minimize the risk of needle stick injuries for healthcare workers and patients.

- Improved patient compliance: The convenience of pre-filled syringes and auto-injectors contributes to improved patient compliance with vaccination schedules.

- Cost-effectiveness in the long run: While the initial cost might be higher, pre-filled syringes and auto-injectors can lead to cost savings in the long run through reduced waste and improved efficiency.

Conclusion

The vaccine packaging market is experiencing robust growth fueled by rising vaccination rates, technological advancements, stringent regulatory compliance, the impact of the COVID-19 pandemic, and increasing demand for convenient delivery systems like pre-filled syringes and auto-injectors. Understanding these key factors is critical for stakeholders across the pharmaceutical supply chain. To stay informed about the latest developments and innovations in this dynamic market, continue researching and exploring the latest trends in vaccine packaging. Invest in understanding the crucial role of vaccine packaging solutions for a secure and effective global vaccination strategy. The future of global health depends on efficient and reliable vaccine delivery, and innovative vaccine packaging is key to achieving this goal.

Featured Posts

-

Harga Kawasaki Ninja 500 Dan 500 Se 2025 Prediksi Dan Spesifikasi

May 30, 2025

Harga Kawasaki Ninja 500 Dan 500 Se 2025 Prediksi Dan Spesifikasi

May 30, 2025 -

Kawasaki Vulcan S 2025 Spesifikasi Dan Harga Di Indonesia

May 30, 2025

Kawasaki Vulcan S 2025 Spesifikasi Dan Harga Di Indonesia

May 30, 2025 -

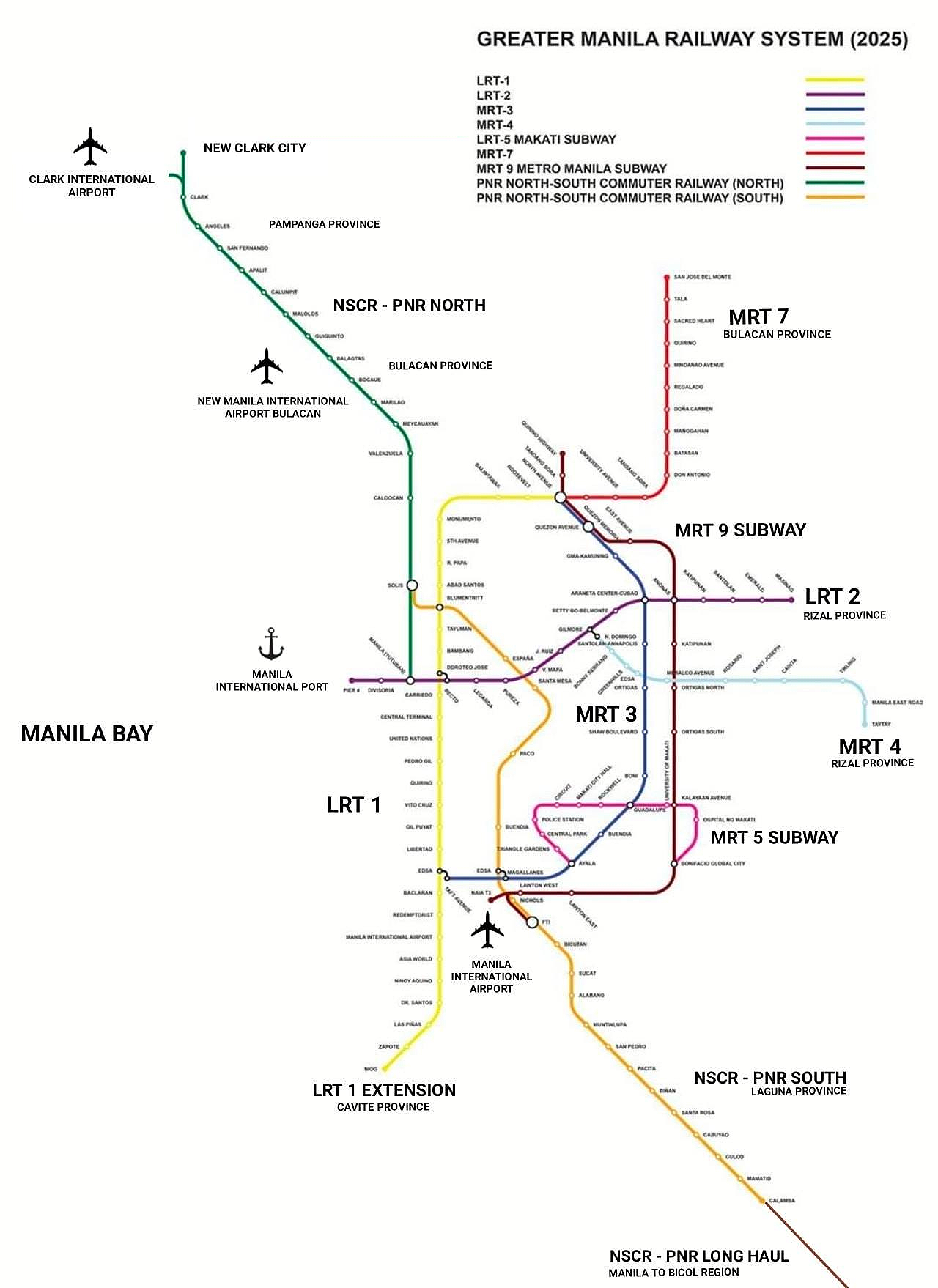

The Future Of Manila Bay A Question Of Sustainability

May 30, 2025

The Future Of Manila Bay A Question Of Sustainability

May 30, 2025 -

Best Kawasaki Ninja Deals R45 000 Discount

May 30, 2025

Best Kawasaki Ninja Deals R45 000 Discount

May 30, 2025 -

Bruno Fernandes O Magnifico Portugues E Seu Impacto No Manchester United

May 30, 2025

Bruno Fernandes O Magnifico Portugues E Seu Impacto No Manchester United

May 30, 2025