Increased Cybersecurity Spending: 63.5% Of Manufacturers Invest In Enhanced Security

Table of Contents

Driving Forces Behind Increased Cybersecurity Investment in Manufacturing

The Growing Threat Landscape

The manufacturing industry is facing an increasingly sophisticated and frequent barrage of cyberattacks targeting Industrial Control Systems (ICS). These attacks are no longer isolated incidents; they represent a significant and evolving threat to operational stability and data integrity. Successful attacks often result in extended production downtime, costly data breaches exposing sensitive customer information and intellectual property, and crippling ransomware attacks that halt entire production lines. The financial repercussions can be devastating.

Furthermore, rising regulatory compliance costs are adding significant pressure on manufacturers to enhance their cybersecurity posture. Regulations like the General Data Protection Regulation (GDPR) and the NIST Cybersecurity Framework impose strict requirements on data protection and security practices, leading to increased investment in compliance-related technologies and expertise. Failure to comply can result in hefty fines and legal repercussions.

- Outdated software and operating systems: Many manufacturing facilities still rely on legacy systems with known vulnerabilities.

- Weak or easily guessed passwords: Inadequate password policies leave systems vulnerable to brute-force attacks.

- Lack of employee cybersecurity awareness training: Employees can inadvertently become entry points for malicious actors through phishing scams or social engineering tactics.

- Insufficient network segmentation: A lack of segmentation allows a compromised system to easily spread malware throughout the entire network.

The Value of Data Protection in Manufacturing

Manufacturing companies hold a wealth of sensitive data, including customer information, intellectual property (IP) related to product designs and manufacturing processes, and supply chain data. Protecting this data is not merely a regulatory requirement; it's crucial for maintaining a competitive advantage and ensuring business continuity. Data breaches can lead to significant financial penalties, loss of customer trust, and long-term reputational damage. The cost of recovering from a data breach often far exceeds the cost of implementing preventative measures.

- Customer Personally Identifiable Information (PII): Names, addresses, credit card details, etc.

- Product designs and blueprints: Valuable intellectual property that provides a competitive edge.

- Supply chain data: Information on suppliers, logistics, and inventory levels, which could be used for sabotage or theft.

- Internal financial data: Sensitive financial information that could be used for fraud.

Improving Operational Resilience and Productivity

Investing in robust cybersecurity is not just about mitigating risks; it's about improving operational resilience and enhancing productivity. By implementing advanced security measures, manufacturers can minimize downtime caused by cyberattacks, ensuring smoother operations and increased efficiency. Real-time threat detection and automated incident response capabilities allow for faster resolution of security incidents, preventing significant disruptions to production.

- Real-time threat detection: Quickly identify and respond to malicious activity before it causes significant damage.

- Automated incident response: Automate the process of containing and remediating security incidents, minimizing human intervention and reducing response times.

- Improved data backup and recovery: Ensure business continuity by having robust data backup and recovery processes in place.

- Enhanced employee productivity: Reduce the time spent dealing with security incidents and allow employees to focus on core business functions.

Key Cybersecurity Measures Adopted by Manufacturers

Investing in Advanced Threat Detection and Response Systems

Manufacturers are increasingly adopting advanced threat detection and response systems to proactively identify and neutralize cyber threats. This includes implementing Intrusion Detection/Prevention Systems (IDS/IPS) to monitor network traffic for malicious activity, Security Information and Event Management (SIEM) solutions to collect and analyze security logs from various sources, and Endpoint Detection and Response (EDR) technologies to monitor and protect individual devices.

- AI-powered threat detection: Leverage artificial intelligence to identify sophisticated and evolving threats that traditional security systems might miss.

- Automated vulnerability patching: Automatically patch vulnerabilities in software and systems to minimize the attack surface.

- Threat intelligence feeds: Stay informed about the latest threats and vulnerabilities to proactively protect against known attacks.

Strengthening Network Security Infrastructure

A robust network security infrastructure is paramount for protecting manufacturing operations. This involves implementing strong firewalls to control network access, implementing network segmentation to isolate critical systems from less critical ones, and enhancing access control and authentication mechanisms such as multi-factor authentication (MFA) to prevent unauthorized access. Regular security audits and penetration testing help identify vulnerabilities before they can be exploited.

- Zero Trust Security Model: Employ a Zero Trust model, assuming no implicit trust and verifying every access request.

- Industrial Control System (ICS) security: Implement specific security measures for ICS and Operational Technology (OT) networks, which often have unique vulnerabilities.

- Regular vulnerability scanning: Regularly scan systems and networks for vulnerabilities and address them promptly.

Prioritizing Employee Cybersecurity Training and Awareness

Employees are often the weakest link in a manufacturing company's security chain. Educating employees about phishing scams, social engineering attacks, and other cybersecurity threats is crucial for preventing successful attacks. Regular security awareness training programs, coupled with strong password policies and multi-factor authentication (MFA), can significantly reduce the risk of human error contributing to a breach.

- Interactive security awareness training: Use engaging methods to teach employees about cybersecurity best practices.

- Simulated phishing campaigns: Test employees' ability to identify phishing emails and other social engineering tactics.

- Regular security updates and communications: Keep employees informed about the latest cybersecurity threats and best practices.

Conclusion: The Future of Cybersecurity Spending in Manufacturing

The increased cybersecurity spending in the manufacturing sector is driven by a confluence of factors: a growing threat landscape, the rising cost of regulatory compliance, and the imperative to protect valuable data and maintain operational resilience. Manufacturers are responding by investing in advanced threat detection and response systems, strengthening their network security infrastructure, and prioritizing employee cybersecurity training. Proactive cybersecurity investments are no longer a luxury; they are a necessity for long-term success in the manufacturing industry.

Don't wait for a cyberattack to strike. Take control of your manufacturing security and invest in increased cybersecurity spending today. A proactive approach to cybersecurity is not merely a cost; it's a strategic investment in the future of your business.

Featured Posts

-

Indore Reaches 40 C Heatwave Advisory And Precautions To Follow

May 13, 2025

Indore Reaches 40 C Heatwave Advisory And Precautions To Follow

May 13, 2025 -

A Critical Examination Of The Da Vinci Codes Literary Merit

May 13, 2025

A Critical Examination Of The Da Vinci Codes Literary Merit

May 13, 2025 -

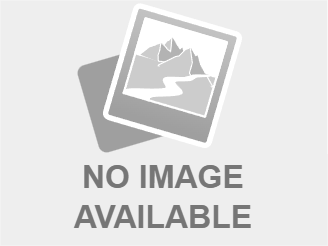

O Kataklysmos Tis Mesogeioy Mia Epistimoniki Proseggisi

May 13, 2025

O Kataklysmos Tis Mesogeioy Mia Epistimoniki Proseggisi

May 13, 2025 -

Exploring The Themes Of The Hobbit The Battle Of The Five Armies

May 13, 2025

Exploring The Themes Of The Hobbit The Battle Of The Five Armies

May 13, 2025 -

Cubs Game 25 2025 Heroes Goats And Key Moments

May 13, 2025

Cubs Game 25 2025 Heroes Goats And Key Moments

May 13, 2025