Growth Drivers And Challenges In The Vaccine Packaging Market

Table of Contents

Key Growth Drivers in the Vaccine Packaging Market

Several factors are propelling the growth of the vaccine packaging market. Understanding these drivers is crucial for businesses involved in vaccine production, distribution, and packaging.

Rising Vaccination Rates and Global Immunization Programs

Increased awareness of vaccine benefits and government initiatives promoting vaccination worldwide are fueling demand for effective and reliable vaccine packaging. This heightened demand stems from several key factors:

- Expanded vaccination programs for childhood diseases: Global efforts to eradicate or significantly reduce the incidence of vaccine-preventable diseases like measles, polio, and rubella are driving substantial demand for vaccine packaging solutions.

- Increasing elderly populations requiring influenza and pneumonia vaccines: The aging global population necessitates increased production and packaging of vaccines targeting age-related illnesses.

- Rising incidence of vaccine-preventable diseases: Outbreaks of diseases such as measles highlight the continued need for robust vaccination programs and, consequently, increased packaging requirements.

The World Health Organization (WHO) actively promotes global immunization programs, significantly impacting the demand for safe and effective vaccine packaging. The success of these programs directly correlates with the availability of high-quality packaging that maintains vaccine potency throughout the supply chain. For example, the success of the global polio eradication initiative has demonstrated the crucial role of efficient vaccine packaging and cold chain management.

Advancements in Vaccine Technology

The development of novel vaccine formulations is a major driver of innovation within the vaccine packaging market. New vaccine technologies demand specialized packaging solutions to maintain their efficacy and stability. Key advancements include:

- Development of mRNA vaccines: The rapid development and deployment of mRNA vaccines against COVID-19 highlighted the need for specialized packaging that can maintain the integrity of these sensitive formulations. This includes maintaining ultra-low temperatures and protecting against degradation.

- Thermostable vaccines: The development of vaccines that are stable at higher temperatures reduces the reliance on extensive cold chain infrastructure, but still requires specialized packaging to maintain potency and prevent contamination.

- Personalized vaccines: The emergence of personalized vaccines, tailored to individual genetic profiles, necessitates innovative packaging solutions to ensure accurate identification and administration.

These advancements necessitate packaging that addresses the unique requirements of each vaccine type, including considerations such as vial size, closure types (e.g., lyophilized vaccines often require specific stoppers and seals), and material compatibility.

Stringent Regulatory Compliance and Safety Standards

Strict regulations governing vaccine storage, transportation, and handling are a significant driver of the vaccine packaging market. Compliance with these regulations necessitates the use of high-quality, compliant packaging materials and processes. Key aspects include:

- Good Manufacturing Practices (GMP) compliance: Vaccine packaging manufacturers must adhere to strict GMP guidelines to ensure the quality, safety, and efficacy of the packaged vaccines.

- Cold chain management regulations: Regulations mandate the maintenance of specific temperature ranges throughout the vaccine's journey from manufacturing to administration. This necessitates packaging with temperature-monitoring and -control capabilities.

- Traceability requirements: Regulations often mandate serialization and track-and-trace systems to ensure product authenticity and prevent counterfeiting.

Meeting these stringent international regulatory standards, such as those set by the WHO and various national regulatory bodies, is essential for vaccine manufacturers and packaging suppliers. Non-compliance can lead to significant penalties and reputational damage.

Challenges Faced by the Vaccine Packaging Market

Despite the significant growth potential, the vaccine packaging market faces considerable challenges:

Maintaining the Cold Chain

Ensuring vaccine potency throughout the supply chain is a major challenge, particularly in remote or resource-limited settings. Key aspects include:

- Challenges of transporting vaccines in remote areas: Maintaining the cold chain in areas with limited infrastructure and unreliable electricity poses a significant logistical hurdle.

- Costs associated with cold chain logistics: The high costs associated with maintaining the cold chain, including specialized equipment and transportation, can significantly impact the overall cost of vaccines.

- Technological advancements in cold chain packaging: Innovations such as temperature-indicating devices, passive and active temperature-controlled containers, and improved insulation materials are crucial to overcoming cold chain challenges.

Cold chain failures can lead to vaccine spoilage and significant health consequences, highlighting the critical need for reliable and cost-effective cold chain solutions. Case studies of past failures underscore the importance of robust cold chain management systems.

Need for Specialized Packaging Materials

Vaccines demand specialized materials to maintain sterility, prevent degradation, and ensure efficacy. This involves the use of:

- Glass vials: Glass vials remain a common choice due to their inertness and compatibility with various vaccine formulations.

- Pre-filled syringes: Pre-filled syringes offer convenience and reduce the risk of contamination during administration.

- Special coatings: Coatings can protect vaccines from environmental factors and improve their shelf life.

- Tamper-evident seals: Tamper-evident seals ensure product integrity and prevent unauthorized access.

The selection of packaging materials requires careful consideration of factors such as cost, compatibility with the vaccine formulation, and environmental impact. The growing demand for sustainable packaging solutions is pushing innovation in this area.

Product Traceability and Security

Preventing counterfeiting and ensuring product authenticity are critical for vaccine safety and public health. This involves:

- Implementation of track-and-trace technologies: Serialization and track-and-trace systems enable the monitoring of vaccine movement throughout the supply chain.

- Anti-counterfeiting measures: Various technologies are employed to prevent the production and distribution of counterfeit vaccines, protecting public health.

- Serialization solutions: Unique identification codes enable the tracking of individual vaccine doses, facilitating recall efforts and preventing fraud.

The implementation of robust track-and-trace systems is crucial for building trust and ensuring the safety and efficacy of vaccines. These systems help identify and remove counterfeit products from the market, protecting populations from potentially harmful substances.

Conclusion

The vaccine packaging market is poised for continued growth, driven by rising vaccination rates, technological advancements in vaccine formulations, and stringent regulatory compliance requirements. However, the challenges associated with maintaining the cold chain, the need for specialized packaging materials, and the importance of product traceability and security demand continuous innovation and collaboration across the industry. Overcoming these challenges is essential for ensuring the safe and effective delivery of vaccines globally. Staying informed about the latest trends and technologies in the vaccine packaging market is crucial for all stakeholders. By embracing innovation and collaboration, the industry can contribute to improving global health outcomes. Learn more about the latest innovations in the vaccine packaging market by visiting [insert link to relevant resource].

Featured Posts

-

Dominant Raducanu Races Into Miami Open Last 16

May 30, 2025

Dominant Raducanu Races Into Miami Open Last 16

May 30, 2025 -

Lw Ansf Alqwmu Nhw Mstqbl Afdl Fy Dhkra Astqlalna

May 30, 2025

Lw Ansf Alqwmu Nhw Mstqbl Afdl Fy Dhkra Astqlalna

May 30, 2025 -

Gorillazs 25th Anniversary A Look At The House Of Kong Exhibition And London Events

May 30, 2025

Gorillazs 25th Anniversary A Look At The House Of Kong Exhibition And London Events

May 30, 2025 -

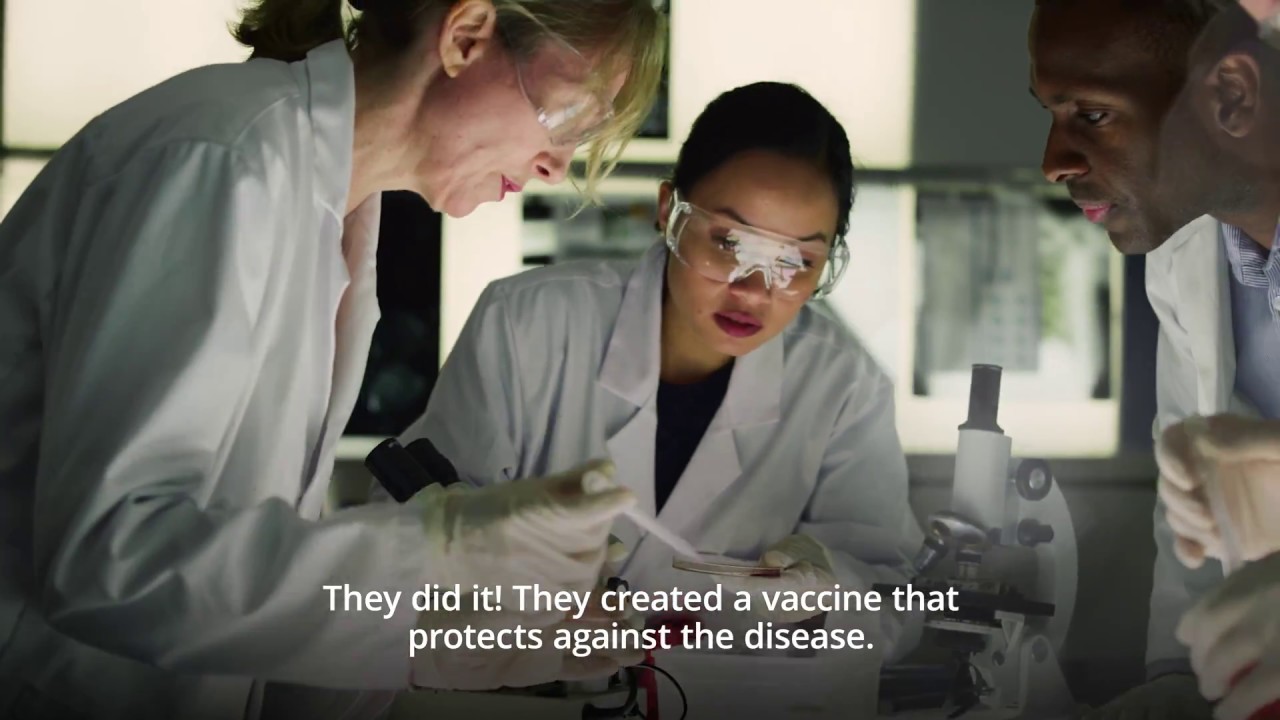

Recours De L Etat Le Projet A69 Au Sud Ouest Reprend Il Vie

May 30, 2025

Recours De L Etat Le Projet A69 Au Sud Ouest Reprend Il Vie

May 30, 2025 -

Beyond The Baseline Analyzing The Unacceptable Behavior Towards Competitors At The French Open

May 30, 2025

Beyond The Baseline Analyzing The Unacceptable Behavior Towards Competitors At The French Open

May 30, 2025