Exploring The Booming Demand For Vaccine Packaging Solutions

Table of Contents

The Rising Need for Temperature-Controlled Vaccine Packaging

Maintaining the cold chain is paramount for vaccine efficacy. Temperature excursions can significantly reduce the potency of vaccines, rendering them ineffective and potentially dangerous. This necessitates the use of specialized temperature-controlled packaging solutions designed to maintain the required temperature range throughout transport and storage.

- Types of temperature-controlled packaging: This includes insulated containers, vaccine carriers, thermal shippers, and specialized refrigerators designed for vaccine transport. The choice of packaging depends on the vaccine's specific temperature requirements, the duration of transport, and the ambient temperature conditions.

- Importance of temperature monitoring and data logging devices: These devices provide crucial real-time data on the temperature of the vaccine shipment, ensuring that the cold chain remains unbroken. This data is essential for regulatory compliance and for identifying any potential temperature excursions that might compromise vaccine quality.

- Challenges in maintaining the cold chain in diverse geographical locations: Maintaining the cold chain presents significant challenges in regions with unreliable electricity grids, limited access to refrigeration, and extreme temperature fluctuations. This necessitates the development of robust and reliable packaging solutions capable of withstanding these harsh conditions.

- Innovations in passive and active temperature control systems: Passive systems rely on insulation and phase-change materials to maintain temperature, while active systems use refrigeration technology. Innovations in both areas are constantly improving the efficiency and reliability of temperature control in vaccine packaging.

Climate change further exacerbates the challenges of cold chain management, leading to more frequent and intense heat waves that increase the risk of vaccine spoilage. The need for highly effective, resilient temperature-controlled vaccine packaging solutions is thus more critical than ever. For example, the use of advanced insulation materials like vacuum insulated panels (VIPs) significantly improves the thermal performance of vaccine shippers.

Regulatory Compliance and Vaccine Packaging Standards

The pharmaceutical industry is heavily regulated, and vaccine packaging is subject to stringent requirements to ensure product safety and efficacy. Compliance with global standards, such as WHO guidelines and FDA regulations, is crucial for manufacturers and distributors.

- Importance of tamper-evident packaging: Tamper-evident features help prevent product adulteration and ensure the integrity of the vaccine throughout the supply chain. These features can include seals, labels, or other mechanisms that indicate if the package has been compromised.

- Material compatibility and safety requirements: Packaging materials must be compatible with the vaccine and must not leach harmful substances into the product. Strict regulations govern the types of materials that can be used in vaccine packaging.

- Labeling requirements and traceability: Accurate and comprehensive labeling is essential for identifying the vaccine, its manufacturer, and its expiry date. Traceability systems, such as barcodes and RFID tags, allow for tracking the vaccine throughout its journey.

- Sterility and contamination prevention: Maintaining sterility is crucial to prevent contamination of the vaccine. Vaccine packaging must be designed and manufactured under strict aseptic conditions to minimize the risk of microbial contamination.

Failure to comply with these regulations can result in product recalls, legal penalties, and reputational damage. Rigorous quality control and testing throughout the manufacturing process are therefore essential to ensure compliance and maintain the highest standards of product safety.

Sustainable and Eco-Friendly Vaccine Packaging

The environmental impact of vaccine packaging is increasingly becoming a concern. Traditional packaging materials often contribute to waste and pollution. There is a growing demand for sustainable alternatives.

- Environmental impact of traditional packaging materials: Many conventional materials, like polystyrene and certain plastics, are not biodegradable and contribute to landfill waste. Their production also often involves significant energy consumption.

- Benefits of using eco-friendly alternatives: Biodegradable and recyclable materials offer a more sustainable solution, reducing environmental impact and promoting circular economy principles.

- Challenges in balancing sustainability with performance and cost-effectiveness: Finding sustainable materials that also meet the performance requirements of vaccine packaging (e.g., maintaining temperature stability and preventing contamination) can be challenging, as can balancing sustainability with cost-effectiveness.

- Examples of sustainable packaging materials used in vaccine packaging: Materials such as recycled cardboard, plant-based plastics, and biodegradable films are being increasingly explored and implemented in vaccine packaging.

Industry initiatives and regulations are driving the adoption of sustainable packaging practices. Many organizations are setting targets for reducing their environmental footprint and encouraging the use of eco-friendly packaging materials.

Technological Advancements in Vaccine Packaging

Technological advancements are constantly improving vaccine packaging solutions, enhancing vaccine stability, delivery, and supply chain management.

- Smart packaging incorporating sensors and RFID technology for real-time monitoring: Smart packaging incorporates sensors that monitor temperature, humidity, and other critical parameters, providing real-time data on the condition of the vaccine. RFID tags enable precise tracking of vaccine shipments.

- Advancements in materials science for improved insulation and barrier properties: Innovations in materials science are leading to the development of new materials with enhanced insulation and barrier properties, improving the protection of vaccines from environmental factors.

- Development of novel packaging formats for improved efficiency and handling: New packaging formats, such as pre-filled syringes and single-dose vials, improve efficiency and reduce waste.

- Integration of digital technologies for enhanced supply chain visibility and traceability: Digital technologies, such as blockchain and cloud-based platforms, enhance supply chain visibility and traceability, enabling better monitoring and management of vaccine shipments.

These advancements result in cost savings, reduced waste, and ultimately, improved vaccine safety and efficacy.

Conclusion

The demand for effective vaccine packaging solutions is experiencing exponential growth, driven by increasing vaccination rates, stringent regulatory requirements, and a growing focus on sustainability. The need for temperature-controlled packaging, regulatory compliance, and innovative solutions continues to shape this dynamic market. The integration of sustainable materials and smart technologies is transforming this field, leading to safer, more efficient, and environmentally responsible vaccine delivery systems.

To stay ahead in this booming market, understanding the current trends and future demands for vaccine packaging solutions is crucial. Explore the latest advancements and invest in robust, compliant, and sustainable vaccine packaging to ensure the safe and effective delivery of life-saving vaccines. Contact us to learn more about innovative solutions in vaccine packaging and how we can help you meet the evolving demands of this critical sector.

Featured Posts

-

Qst Alastqlal Ndal Wtdhyat Mn Ajl Alhryt

May 30, 2025

Qst Alastqlal Ndal Wtdhyat Mn Ajl Alhryt

May 30, 2025 -

Setlist Fm Y Ticketmaster Una Alianza Para Mejorar La Compra De Entradas

May 30, 2025

Setlist Fm Y Ticketmaster Una Alianza Para Mejorar La Compra De Entradas

May 30, 2025 -

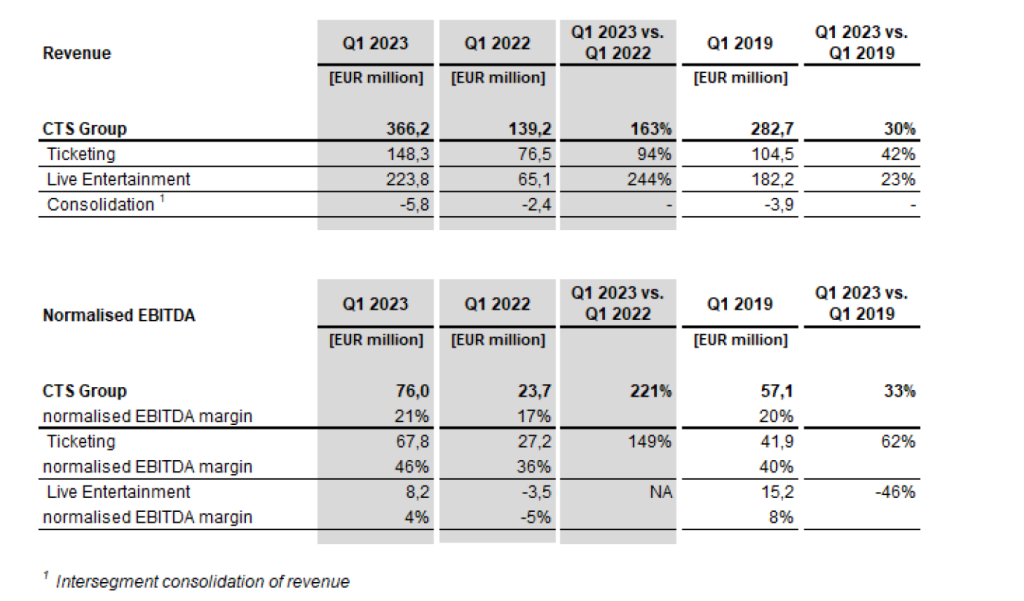

Cts Eventims Strong Start 2024 Growth Report

May 30, 2025

Cts Eventims Strong Start 2024 Growth Report

May 30, 2025 -

Fernando Cabral De Mello Assume Lideranca Da Sony Music Entertainment Brasil

May 30, 2025

Fernando Cabral De Mello Assume Lideranca Da Sony Music Entertainment Brasil

May 30, 2025 -

The Bruno Fernandes Transfer Decision Manchester United Or Tottenham

May 30, 2025

The Bruno Fernandes Transfer Decision Manchester United Or Tottenham

May 30, 2025