Eramet's EraLow: A Breakthrough In Steel Decarbonization

Table of Contents

Understanding the Challenges of Steel Decarbonization

Steel production, traditionally reliant on blast furnaces fueled by coal and coke, is inherently energy-intensive and generates significant carbon emissions. The high temperatures required for the process, combined with the carbon-rich feedstock, lead to substantial CO2 release into the atmosphere. Transitioning to sustainable steel production presents considerable hurdles:

- High initial investment costs: Replacing existing infrastructure with cleaner technologies requires significant upfront capital.

- Scalability challenges: Implementing low-carbon steelmaking processes on an industrial scale presents technological and logistical complexities.

- Technological hurdles: Developing and perfecting alternative technologies capable of matching the efficiency and scale of traditional methods is crucial.

The challenges are multifaceted:

- High energy consumption in blast furnaces: Traditional blast furnaces are notoriously energy-intensive, consuming vast amounts of fossil fuels.

- Significant CO2 emissions from coal-based processes: The combustion of coal and coke in blast furnaces releases massive quantities of CO2.

- Need for alternative, low-carbon feedstocks: Replacing coal and coke with sustainable alternatives is essential for reducing the carbon footprint of steel production.

Eramet's eraLow Technology: A Deep Dive

Eramet's eraLow process represents a paradigm shift in steelmaking. It dramatically reduces reliance on coal and coke by employing innovative methods focused on hydrogen reduction and direct reduced iron (DRI) production. This groundbreaking technology leverages several key advancements:

- Hydrogen Reduction: eraLow utilizes hydrogen as a reducing agent, replacing the carbon-based materials traditionally used. This dramatically decreases CO2 emissions.

- Electric Arc Furnace (EAF): The process integrates electric arc furnaces, which offer greater energy efficiency and control compared to traditional blast furnaces.

- Low-Carbon Feedstocks: Eramet's eraLow utilizes alternative feedstocks that significantly reduce the overall carbon footprint of the process.

The benefits are evident:

- Process efficiency and energy savings: eraLow optimizes energy usage, leading to significant cost reductions in the long run.

- Reduced greenhouse gas emissions compared to traditional methods: The switch to hydrogen and electric arc furnaces drastically lowers CO2 emissions.

- Potential for near-zero carbon steel production: With further advancements, eraLow aims to achieve near-zero carbon steel production.

Environmental and Economic Benefits of eraLow

Eramet's eraLow technology offers substantial environmental benefits. While precise figures depend on the specific implementation, the technology promises a significant reduction in CO2 emissions compared to traditional methods – potentially up to 90% or more, depending on the hydrogen source. Beyond CO2 reduction, eraLow contributes to:

- Reduced air and water pollution: By minimizing the use of fossil fuels, the process also reduces air and water pollutants typically associated with traditional steelmaking.

The economic benefits are also compelling:

- Long-term cost savings from reduced energy consumption: The increased efficiency of eraLow translates into lower operating costs over the life cycle of the plant.

- Improved environmental sustainability metrics: Adopting eraLow improves a company's environmental performance, enhancing its brand reputation and attracting environmentally conscious investors. This aligns with the growing demand for sustainable and responsible sourcing.

The Future of eraLow and its Role in the Green Steel Revolution

Eramet plans to scale up eraLow technology significantly in the coming years, aiming for widespread implementation within the steel industry. This expansion will involve:

- Strategic partnerships with other steel producers: Collaboration will accelerate the adoption of eraLow and its integration into existing steel production chains.

Eramet's eraLow technology is not merely an advancement in steel production; it's a critical component of the green steel revolution, contributing significantly to:

- Achieving global climate goals: Widespread adoption of eraLow will substantially reduce the steel industry's contribution to climate change.

Conclusion: Eramet's eraLow: Paving the Way for a Sustainable Steel Future

Eramet's eraLow technology presents a compelling solution for decarbonizing the steel industry. Its significant reduction in carbon emissions, potential for cost savings, and crucial role in the transition to green steel make it a game-changer. Decarbonizing steel production is paramount for a sustainable future, and eraLow offers a viable pathway toward achieving this critical goal. Discover eraLow and learn about green steel solutions that are transforming the industry. Explore sustainable steel alternatives and contribute to a cleaner, greener tomorrow. Learn more about Eramet's commitment to sustainable steel production by visiting their website and exploring the exciting possibilities of eraLow.

Featured Posts

-

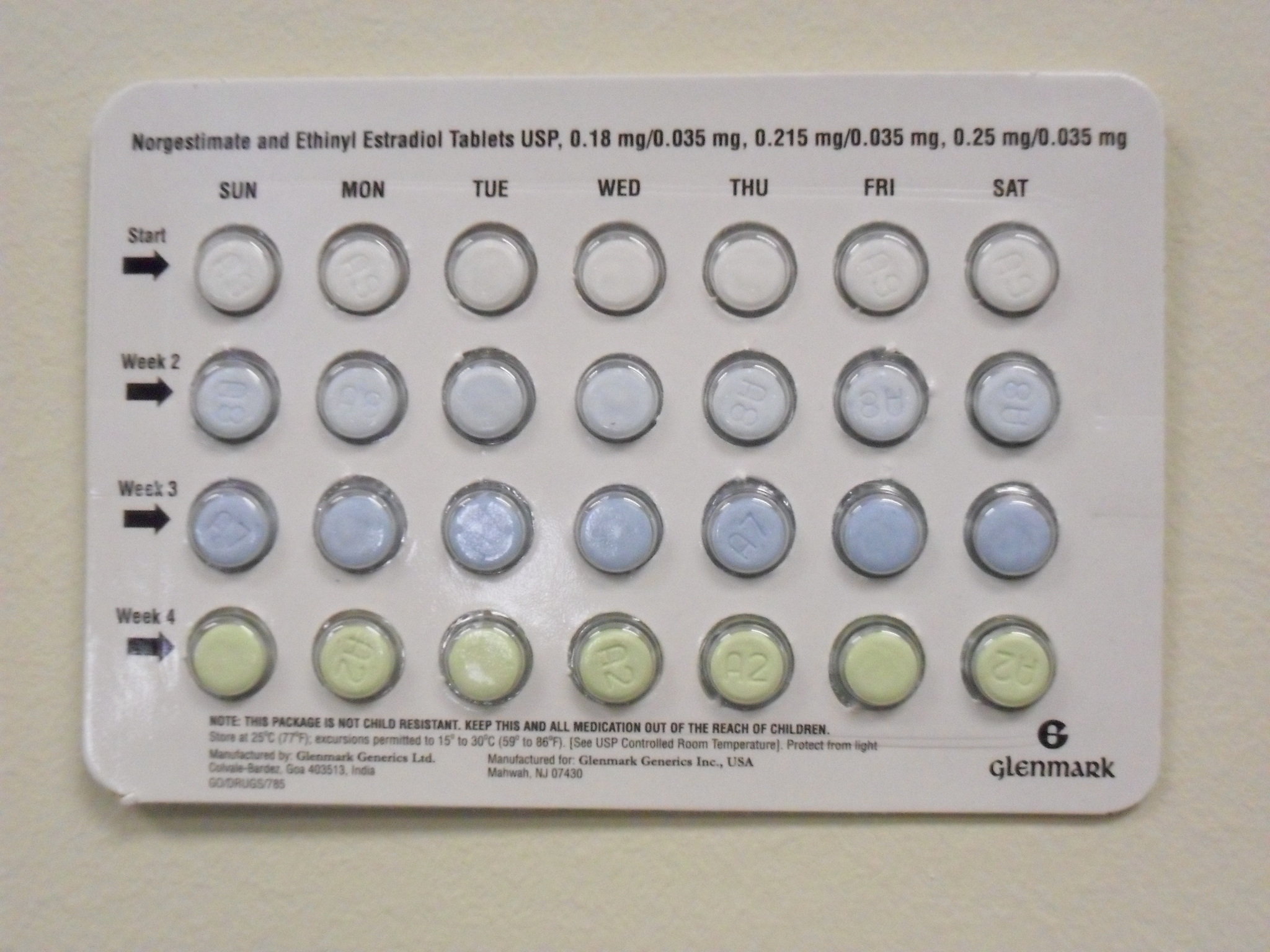

Recall Alert Affected Dressings And Birth Control Pills In Ontario And Canada

May 14, 2025

Recall Alert Affected Dressings And Birth Control Pills In Ontario And Canada

May 14, 2025 -

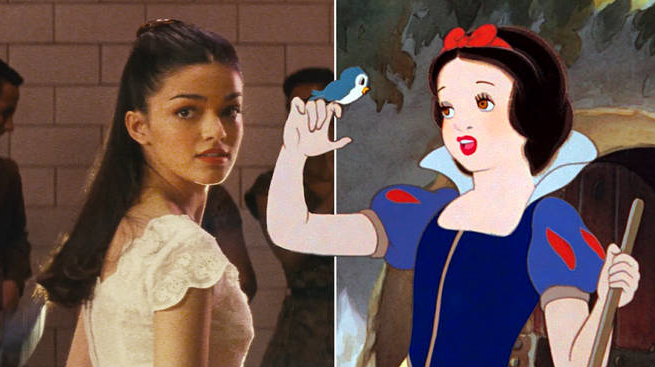

Disneys Snow White Live Action Streaming Options And Release Details

May 14, 2025

Disneys Snow White Live Action Streaming Options And Release Details

May 14, 2025 -

Daria Kasatkinas Australian Debut Wta Rankings And First Day Celebration

May 14, 2025

Daria Kasatkinas Australian Debut Wta Rankings And First Day Celebration

May 14, 2025 -

Un Algerien Expulse De France Pour Ses Propos Sur Le Genocide A Gaza

May 14, 2025

Un Algerien Expulse De France Pour Ses Propos Sur Le Genocide A Gaza

May 14, 2025 -

Taenaeaen Arvottu Eurojackpot Katso Oikea Numeroryhmae Ilta Sanomista

May 14, 2025

Taenaeaen Arvottu Eurojackpot Katso Oikea Numeroryhmae Ilta Sanomista

May 14, 2025

Latest Posts

-

Mfd Spring Break A Eurovangelist Initiative

May 14, 2025

Mfd Spring Break A Eurovangelist Initiative

May 14, 2025 -

Mfd Spring Break Eurovangelists Impact

May 14, 2025

Mfd Spring Break Eurovangelists Impact

May 14, 2025 -

Eurovangelists Launch Mfd Spring Break

May 14, 2025

Eurovangelists Launch Mfd Spring Break

May 14, 2025 -

Uruguay Orsi Inicia Gestion Con Enfoque En Reformas Balanceadas

May 14, 2025

Uruguay Orsi Inicia Gestion Con Enfoque En Reformas Balanceadas

May 14, 2025 -

Episode 58 A Look At Serbia Denmark And Germanys Future 2025

May 14, 2025

Episode 58 A Look At Serbia Denmark And Germanys Future 2025

May 14, 2025