Enhanced Automated Visual Inspection Of Lyophilized Vials: A Practical Guide

Table of Contents

The limitations of traditional manual inspection are well-documented. Human inspectors can experience fatigue, leading to oversight of critical defects. Subjectivity in interpretation also leads to inconsistencies in quality assessment. Moreover, manual inspection is a bottleneck in the production process, significantly limiting throughput. Automated visual inspection systems offer a robust solution to these problems, improving quality control, increasing efficiency, and ultimately reducing costs.

Benefits of Automated Visual Inspection Systems for Lyophilized Vials

Automated visual inspection systems revolutionize lyophilized vial inspection by offering several key advantages:

Improved Accuracy and Reduced Human Error

Automated systems eliminate the subjectivity inherent in manual inspection. Unlike human inspectors, machines consistently apply pre-defined criteria, leading to significantly higher accuracy rates. This results in the reliable detection of various defects, including:

- Cracks: Automated systems can detect even hairline fractures in the vial glass, which might be missed by the human eye.

- Particulate Matter: Microscopic particles within the lyophilized product are easily identified and quantified.

- Delamination: Separation of the lyophilized cake from the vial wall is readily detectable.

Studies have shown that automated systems achieve accuracy rates exceeding 99%, a significant improvement over manual inspection's typical 85-95% accuracy. This enhanced precision ensures that only vials meeting the highest quality standards are released.

Increased Throughput and Efficiency

Automated visual inspection dramatically speeds up the inspection process. A single automated system can inspect thousands of vials per hour, compared to the significantly lower throughput of manual inspection. This translates to:

- Reduced Production Timelines: Faster inspection means faster release of finished goods, reducing lead times and improving overall production efficiency.

- Increased Manufacturing Capacity: Automated systems allow for greater production output without increasing labor costs.

For example, an automated system might inspect 10,000 vials per hour, while a team of human inspectors might only manage 1,000-2,000 vials in the same timeframe, representing a 5-10x increase in throughput.

Enhanced Data Management and Traceability

Automated systems generate comprehensive, auditable inspection reports, including:

- Detailed Defect Information: Type, location, and severity of each defect are meticulously recorded.

- Real-time Data: Inspection data is collected and analyzed in real-time, enabling immediate corrective actions.

- Full Traceability: Complete records of all inspected vials and their associated data ensure compliance with stringent regulatory requirements, such as 21 CFR Part 11.

This enhanced data management capability facilitates thorough analysis, enabling process optimization and continuous improvement of the lyophilization process.

Key Features of Advanced Automated Visual Inspection Systems

Modern automated visual inspection systems incorporate several advanced features to ensure optimal performance:

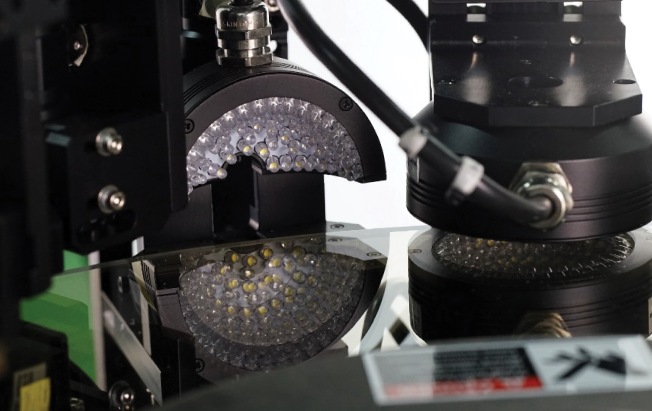

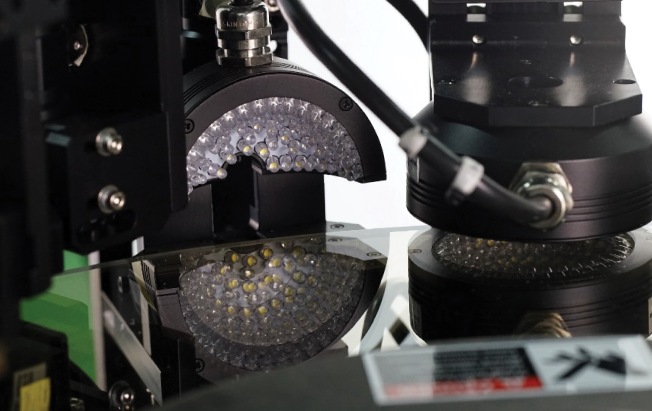

High-Resolution Imaging and Advanced Algorithms

These systems utilize:

- High-Resolution Cameras: Capture highly detailed images of each vial, revealing even the smallest defects.

- Advanced Lighting Techniques: Employ various lighting schemes (e.g., brightfield, darkfield) to maximize defect visibility.

- Sophisticated Algorithms: Utilize AI and machine learning to analyze images, identify defects with high sensitivity and specificity, and classify them accurately. These algorithms are continuously refined and improved to adapt to evolving challenges.

Integration with Existing Production Lines

Automated systems are designed for seamless integration into existing pharmaceutical manufacturing workflows. They are:

- Flexible and Adaptable: Capable of handling different vial sizes and formats.

- Easily Validated: Designed to meet rigorous validation and qualification requirements, ensuring compliance with industry standards.

- Modular and Scalable: Allow for easy expansion as production needs grow.

Real-time Defect Classification and Reporting

Automated systems provide:

- Immediate Feedback: Inspectors receive real-time alerts about detected defects, enabling immediate corrective actions.

- Automated Reporting: Generate detailed reports, including images and classifications of detected defects, streamlining data analysis.

- Automated Rejection: Many systems can automatically reject faulty vials, preventing defective products from entering the supply chain.

Selecting the Right Automated Visual Inspection System

Choosing the right system requires careful consideration of several factors:

Consideration of Vial Type and Production Capacity

The system must be compatible with:

- Specific Vial Types: Various vial sizes, shapes, and materials need to be accounted for.

- Production Throughput: The system's speed and capacity should meet current and future production demands.

Regulatory Compliance and Validation Requirements

Ensuring compliance is paramount:

- 21 CFR Part 11 Compliance: The system must adhere to all relevant regulatory standards.

- Validation and Qualification: Thorough validation and qualification procedures are essential to demonstrate system accuracy and reliability.

Cost and ROI Analysis

A thorough cost-benefit analysis is crucial:

- Initial Investment: Consider the upfront cost of the system and its installation.

- Return on Investment (ROI): Evaluate the long-term cost savings from improved efficiency, reduced labor costs, and minimized product waste.

Conclusion

Enhanced Automated Visual Inspection of Lyophilized Vials offers significant advantages over traditional manual methods. Improved accuracy, increased throughput, and enhanced data management contribute to higher product quality, reduced costs, and increased regulatory compliance. By investing in advanced automated systems, pharmaceutical manufacturers can optimize their quality control processes and enhance overall production efficiency. Invest in enhanced automated visual inspection of lyophilized vials today for a future of improved quality and efficiency. Learn more about how to upgrade your lyophilized vial inspection with automated solutions and contact us today.

Featured Posts

-

Next Pope Predicting The Outcome From The Conclave Of Cardinals

May 11, 2025

Next Pope Predicting The Outcome From The Conclave Of Cardinals

May 11, 2025 -

Conor Mc Gregor Supports Bkfc Fighter A Repeat Of The Famous Aldo Confrontation

May 11, 2025

Conor Mc Gregor Supports Bkfc Fighter A Repeat Of The Famous Aldo Confrontation

May 11, 2025 -

The Devastating Consequences Of Israels Gaza Blockade

May 11, 2025

The Devastating Consequences Of Israels Gaza Blockade

May 11, 2025 -

Did Jessica Simpson Really Say She Drinks Snake Sperm A Comprehensive Investigation

May 11, 2025

Did Jessica Simpson Really Say She Drinks Snake Sperm A Comprehensive Investigation

May 11, 2025 -

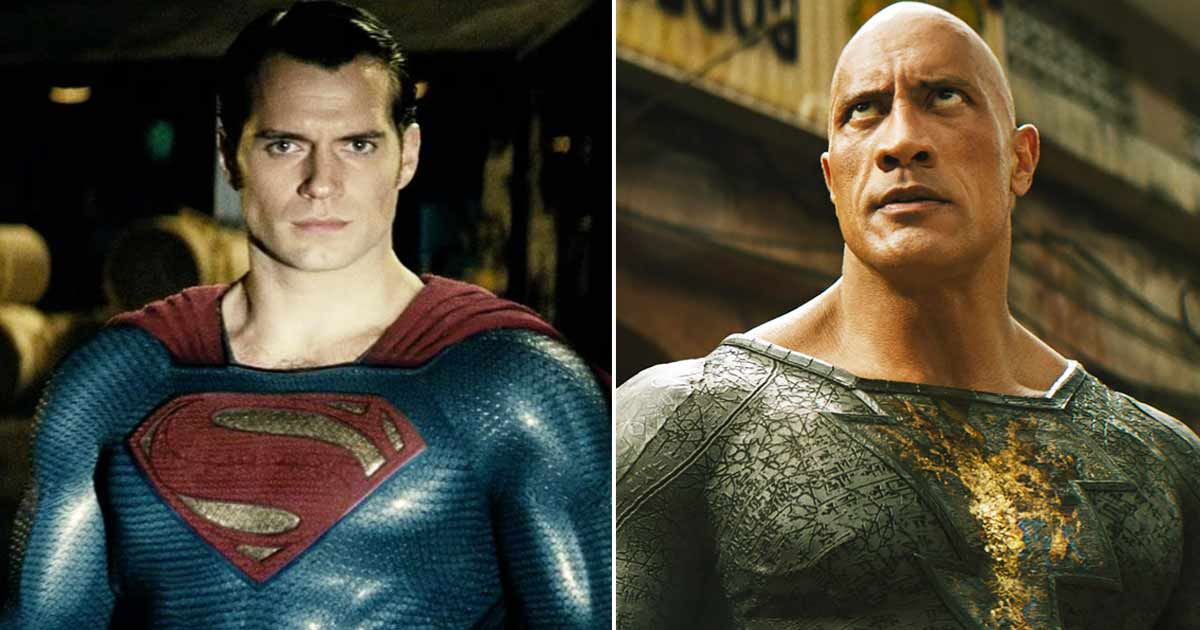

Henry Cavills Superman Departure James Gunns Account Of Past Mismanagement

May 11, 2025

Henry Cavills Superman Departure James Gunns Account Of Past Mismanagement

May 11, 2025

Latest Posts

-

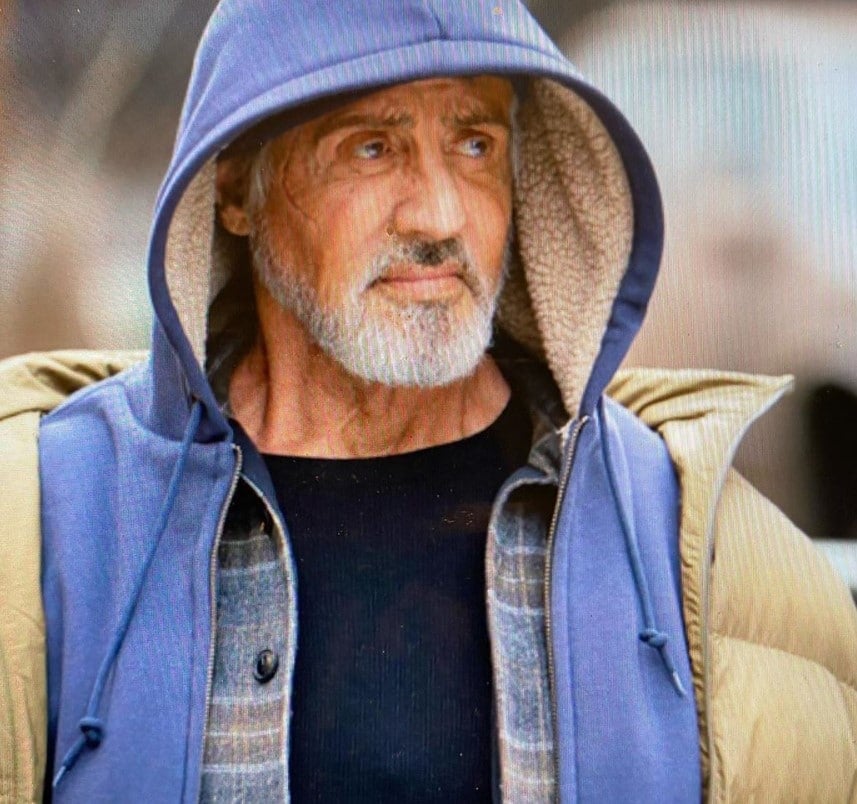

Stallones Favorite Rocky Unveiling The Franchises Most Poignant Chapter

May 12, 2025

Stallones Favorite Rocky Unveiling The Franchises Most Poignant Chapter

May 12, 2025 -

Which Rocky Movie Touches Stallone The Most The Actor Names His Emotional Favorite

May 12, 2025

Which Rocky Movie Touches Stallone The Most The Actor Names His Emotional Favorite

May 12, 2025 -

Rockys Emotional Heart Stallone Reveals His Favorite Film In The Iconic Franchise

May 12, 2025

Rockys Emotional Heart Stallone Reveals His Favorite Film In The Iconic Franchise

May 12, 2025 -

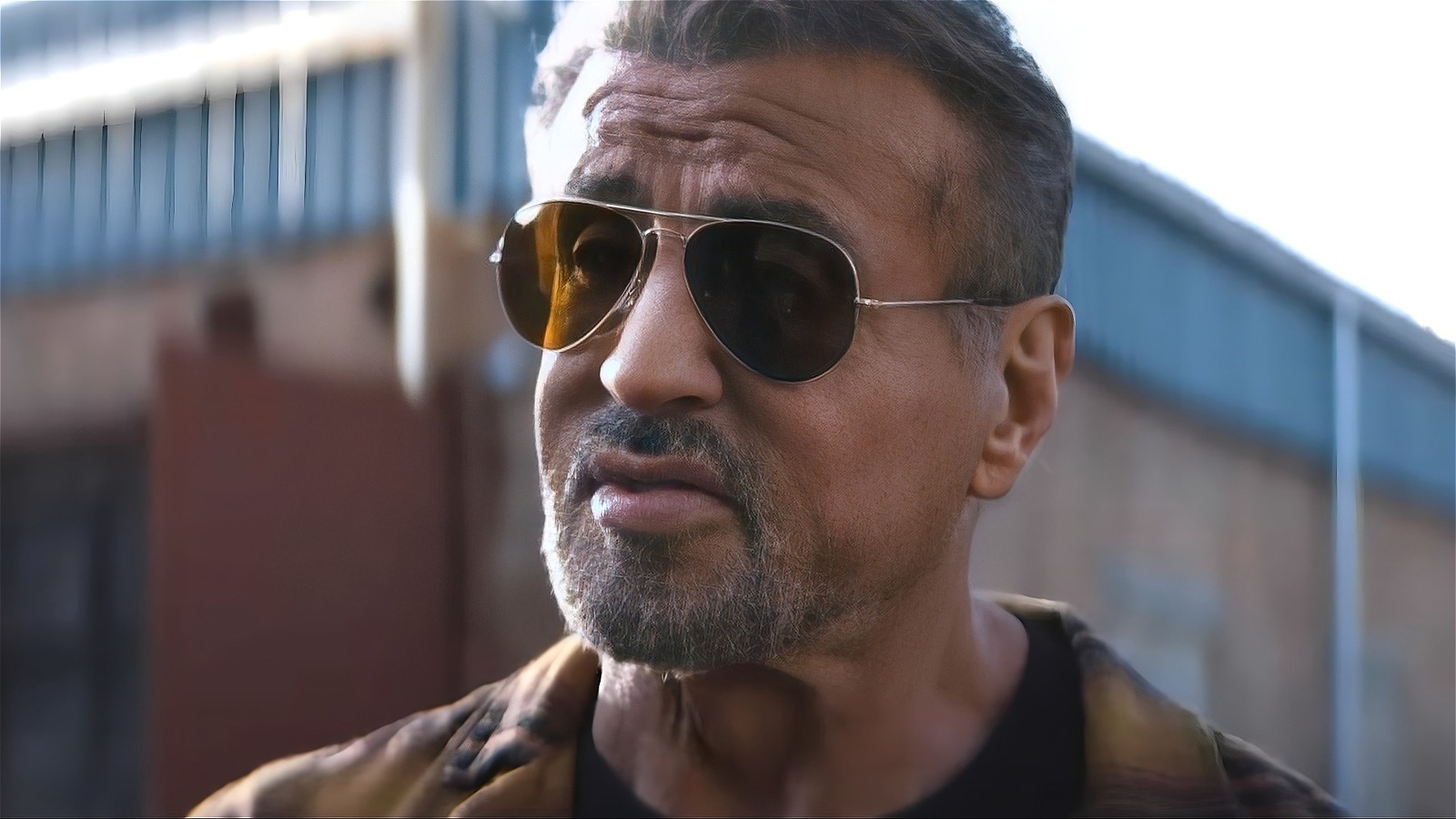

The Forgotten Directing Effort Of Sylvester Stallone A Box Office Bomb

May 12, 2025

The Forgotten Directing Effort Of Sylvester Stallone A Box Office Bomb

May 12, 2025 -

Sylvester Stallones Underrated Directing Career Focusing On His One Non Acting Film

May 12, 2025

Sylvester Stallones Underrated Directing Career Focusing On His One Non Acting Film

May 12, 2025