Electric Motor Supply Chains: Reducing China's Dominance

Table of Contents

The Current State of Electric Motor Supply Chains and China's Role

China's Market Share and Manufacturing Prowess

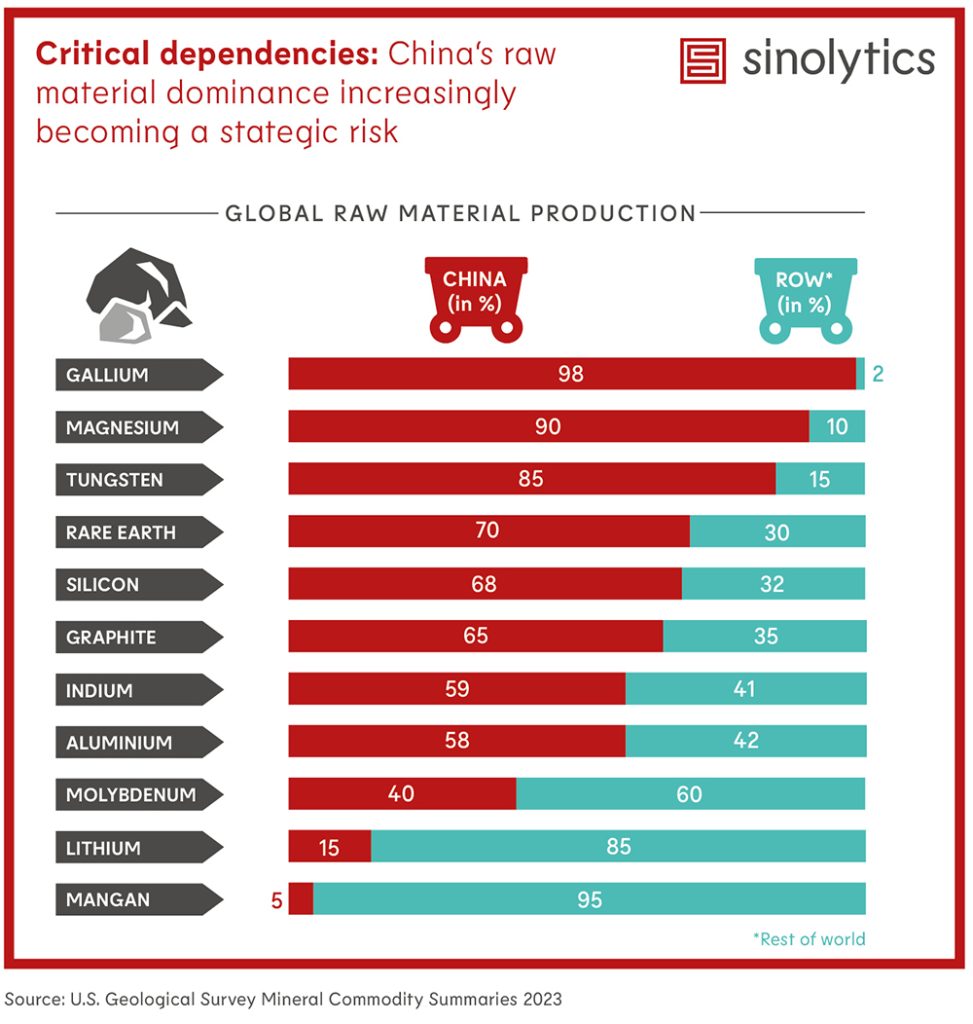

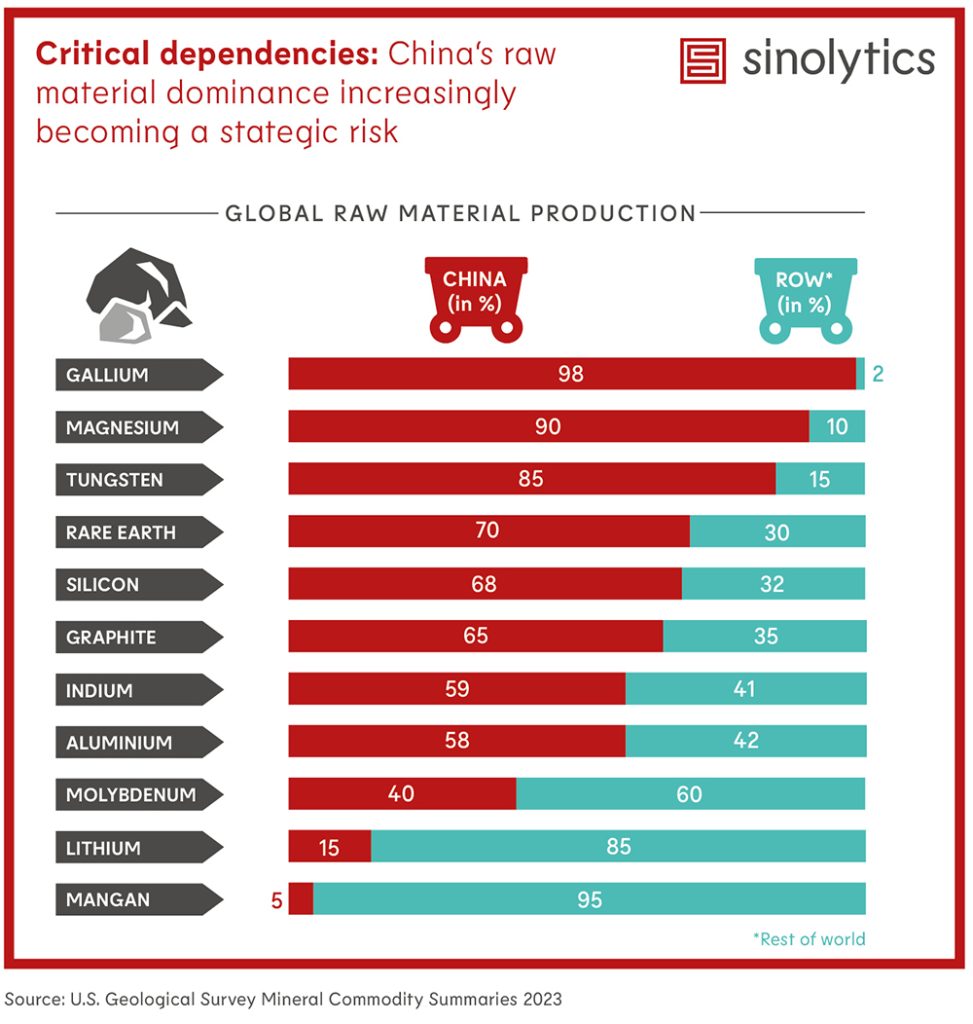

China holds a commanding share of the global electric motor market, estimated to be over 70% in certain segments. This dominance stems from several factors:

- Massive Manufacturing Capacity: China boasts a vast network of electric motor manufacturing facilities, capable of producing enormous quantities at competitive prices. Regions like Guangdong and Jiangsu are major hubs for electric motor production.

- Cost-Effectiveness: Lower labor costs and economies of scale contribute significantly to China's competitive advantage in electric motor manufacturing.

- Access to Raw Materials: China possesses substantial reserves of some key raw materials essential for electric motor production, although reliance on imports for others remains a factor. Leading Chinese electric motor manufacturers like names of companies could be added here leverage these advantages.

Geopolitical Risks and Supply Chain Vulnerabilities

The concentration of electric motor production in China creates significant geopolitical risks:

- Trade Wars and Tariffs: Escalating trade tensions can lead to disruptions in the supply of electric motors, impacting industries reliant on these components.

- Political Instability: Unpredictable political events within China could disrupt manufacturing and exports, creating shortages and price volatility.

- Pandemics and Natural Disasters: The COVID-19 pandemic exposed the fragility of global supply chains, highlighting the risks of relying heavily on a single production center. Disruptions caused by natural disasters could further exacerbate these problems.

- Supply Chain Bottlenecks: Dependence on a single source creates significant vulnerabilities. Even minor disruptions in China can have cascading effects across various industries globally.

Strategies for Diversifying Electric Motor Production

Nearshoring and Reshoring Initiatives

Relocating manufacturing closer to key markets (nearshoring) or back to the home country (reshoring) offers several advantages:

- Reduced Transportation Costs and Lead Times: Nearshoring and reshoring decrease shipping times and costs, improving supply chain efficiency.

- Increased Supply Chain Resilience: Diversification minimizes the impact of geopolitical risks and disruptions in a single region.

- Enhanced Control and Transparency: Companies gain greater oversight of their production processes and supply chains.

However, challenges remain:

- Higher Labor Costs: Labor costs in many developed countries are significantly higher than in China.

- Infrastructure Requirements: Significant investments in infrastructure may be required to support new manufacturing facilities.

- Government Incentives: Governments can play a vital role in incentivizing nearshoring and reshoring through tax breaks and subsidies. Examples include programs in the US and Europe aimed at attracting manufacturing investment.

Investing in Domestic Manufacturing Capabilities

Building domestic electric motor manufacturing capacity is crucial for long-term security:

- Technological Advancements: Investment in research and development (R&D) is key to developing advanced electric motor technologies and manufacturing processes.

- Skilled Labor Development: Training and education programs are vital to create a skilled workforce capable of supporting advanced manufacturing techniques.

- Public-Private Partnerships: Collaboration between governments and private sectors is essential to mobilize resources and expertise.

Securing Raw Material Supply Chains

Diversifying sources of raw materials is essential to minimize vulnerabilities:

- Exploration of Alternative Sources: Identifying and developing new sources of critical raw materials, such as rare earth minerals and copper, is a strategic imperative.

- Recycling Initiatives: Investing in the recycling and reuse of electric motor components can reduce reliance on virgin materials.

- Strategic Partnerships: Developing strong partnerships with mining companies and other suppliers can ensure access to reliable raw material supplies.

- Sustainable Sourcing: Adopting sustainable sourcing practices reduces environmental impacts and promotes ethical sourcing of raw materials.

Technological Advancements and Innovation

Automation and Robotics in Electric Motor Manufacturing

Automation plays a crucial role in enhancing efficiency and reducing costs:

- Improved Quality Control: Automation minimizes human error, leading to higher quality electric motors.

- Increased Efficiency: Automated systems can operate continuously, increasing production output.

- Reduced Labor Costs: While initial investments are significant, automation can reduce long-term labor costs. Examples include automated assembly lines and robotic welding systems.

Advancements in Electric Motor Design and Efficiency

Technological innovations in electric motor design are leading to significant improvements:

- New Materials: The use of advanced materials improves motor efficiency and durability.

- Improved Designs: Innovative designs, such as high-efficiency motors and permanent magnet motors, enhance performance and reduce energy consumption. This can reduce reliance on specific raw materials and manufacturing techniques.

Conclusion

China's dominance in the electric motor supply chain creates substantial geopolitical and economic risks. Diversifying electric motor production is no longer optional; it's a strategic necessity. Nearshoring, reshoring, securing raw materials, and driving technological advancements are crucial steps in building more resilient and diversified supply chains. Governments, businesses, and investors must work collaboratively to foster domestic manufacturing capabilities, support technological innovation, and adopt responsible sourcing practices. Let's actively participate in creating a more robust and globally distributed electric motor supply chain, reducing our reliance on any single nation and ensuring the long-term security of this vital industry.

Featured Posts

-

Stanley Cup Playoffs Us Ratings Decline Global Appeal Remains

May 05, 2025

Stanley Cup Playoffs Us Ratings Decline Global Appeal Remains

May 05, 2025 -

Kentucky Derby 2025 Betting Odds Horses And Expert Picks

May 05, 2025

Kentucky Derby 2025 Betting Odds Horses And Expert Picks

May 05, 2025 -

Christian Horners Comment About Max Verstappen Becoming A Dad

May 05, 2025

Christian Horners Comment About Max Verstappen Becoming A Dad

May 05, 2025 -

Lizzos Dramatic Weight Loss Transformation At The Oscars

May 05, 2025

Lizzos Dramatic Weight Loss Transformation At The Oscars

May 05, 2025 -

Lizzos Stunning La Concert Cinched Waist And Curves Take Center Stage

May 05, 2025

Lizzos Stunning La Concert Cinched Waist And Curves Take Center Stage

May 05, 2025

Latest Posts

-

Ufc 314 Volkanovski Vs Lopes Examining The Pre Fight Betting Lines

May 05, 2025

Ufc 314 Volkanovski Vs Lopes Examining The Pre Fight Betting Lines

May 05, 2025 -

Emma Stones Red Carpet Choice Analyzing The Popcorn Butt Dress Design

May 05, 2025

Emma Stones Red Carpet Choice Analyzing The Popcorn Butt Dress Design

May 05, 2025 -

Betting On Ufc 314 Volkanovski Vs Lopes Main Event Opening Odds

May 05, 2025

Betting On Ufc 314 Volkanovski Vs Lopes Main Event Opening Odds

May 05, 2025 -

Early Ufc 314 Odds Volkanovski Vs Lopes Fight Preview And Betting Insights

May 05, 2025

Early Ufc 314 Odds Volkanovski Vs Lopes Fight Preview And Betting Insights

May 05, 2025 -

Emma Stones Quirky Snl Dress The Popcorn Butt Thats Breaking The Internet

May 05, 2025

Emma Stones Quirky Snl Dress The Popcorn Butt Thats Breaking The Internet

May 05, 2025