Electric Motor Manufacturing: Diversification And The End Of China's Hold

Table of Contents

The Rise of Electric Motor Manufacturing Outside China

The dominance of China in electric motor manufacturing is waning, driven by a confluence of geopolitical and economic factors. This diversification is reshaping the global landscape of this crucial industry.

Geopolitical Factors Driving Diversification:

Increased trade tensions and the imposition of tariffs on Chinese goods have spurred many companies to seek alternative manufacturing locations. Concerns over supply chain vulnerabilities, highlighted by recent global disruptions, further fueled this trend. Reliance on a single manufacturing hub proved risky, prompting a strategic reassessment by numerous businesses. Governments in various countries are actively promoting domestic electric motor manufacturing through substantial incentives and policies.

- The United States: The US government has implemented initiatives like the Inflation Reduction Act, offering significant tax credits and subsidies to encourage domestic EV battery and component production, including electric motors.

- European Union: The EU is promoting its own industrial strategy, focusing on strengthening its domestic manufacturing base and reducing reliance on external suppliers for key technologies like electric motors.

- India: India's "Make in India" initiative aims to boost domestic manufacturing across various sectors, including the automotive and renewable energy industries, which heavily rely on electric motors.

Examples of companies diversifying their electric motor manufacturing include:

- Tesla's expansion into Germany and Texas.

- BMW's investment in electric motor production facilities in Hungary and China.

- Several major automotive suppliers establishing manufacturing plants in Mexico and Southeast Asia.

Economic Factors Fueling the Shift:

Rising labor costs in China have made it less attractive as a manufacturing hub for cost-sensitive industries like electric motor manufacturing. Other regions offer attractive incentives, lower production costs, and access to different raw materials.

- Southeast Asia: Countries like Vietnam and Thailand offer lower labor costs and improved infrastructure, attracting significant foreign investment in manufacturing.

- India: Its large and skilled workforce, coupled with government incentives, presents a compelling alternative to China.

- Mexico: Proximity to the US market and various trade agreements make Mexico an attractive location for North American electric motor manufacturing.

Comparing production and labor costs:

| Region | Labor Costs (relative) | Production Costs (relative) |

|---|---|---|

| China | High | Moderate |

| Southeast Asia | Low | Low |

| India | Low to Moderate | Low to Moderate |

| Mexico | Moderate | Moderate |

Technological Advancements and their Impact on Electric Motor Manufacturing Locations

Technological advancements are also playing a crucial role in shaping the future of electric motor manufacturing locations.

Automation and Robotics in Electric Motor Production:

Automation is reducing the reliance on low-cost labor, shifting the focus towards skilled labor and specialized expertise. This means that access to a skilled workforce, rather than just cheap labor, is becoming a key factor in location decisions.

- Automated assembly lines for high-volume production.

- Robotics for precision tasks and quality control.

- AI-powered systems for predictive maintenance and optimization.

Advancements in Electric Motor Design and Materials:

New materials and designs are impacting manufacturing processes and location selection. The need for specialized facilities and expertise to handle these advanced materials and processes is becoming increasingly important.

- The use of rare earth magnets and their associated supply chain considerations.

- The development of high-efficiency motors with improved power density.

- The adoption of additive manufacturing (3D printing) for customized motor components.

The Future of Electric Motor Manufacturing: A Multipolar Landscape

The future of electric motor manufacturing points towards a multipolar landscape with regional hubs specializing in different aspects of production.

Regional Hubs and Specialized Production:

Regional specialization is emerging, with certain countries focusing on specific motor types or production stages.

- Countries specializing in the production of high-performance electric motors for EVs.

- Regions focusing on the manufacturing of standard electric motors for industrial applications.

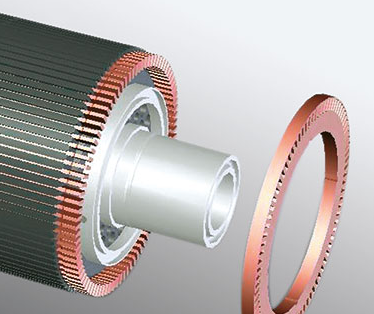

- Specialized facilities for the production of key components like stators and rotors.

This fragmented production model presents both benefits and challenges: benefits include greater resilience to supply chain disruptions and regional economic development, but challenges include increased coordination costs and potential logistical complexities.

Sustainability and Ethical Considerations:

Sustainable manufacturing practices and ethical sourcing are gaining importance in the electric motor industry.

- The use of recycled materials and renewable energy sources in the manufacturing process.

- Focus on responsible labor practices and fair wages throughout the supply chain.

- Implementation of environmental management systems to minimize the environmental impact of production.

Conclusion: The Shifting Landscape of Electric Motor Manufacturing

The diversification of electric motor manufacturing is driven by a complex interplay of geopolitical factors, economic pressures, and technological advancements. China's once dominant position is weakening as manufacturers seek to mitigate risk, access new markets, and leverage technological innovation. The emergence of a multipolar landscape with regional manufacturing hubs and specialized production is reshaping global supply chains. Sustainability and ethical considerations are becoming increasingly important factors in location decisions.

Stay ahead of the curve in the rapidly changing landscape of electric motor manufacturing. Learn more about the diversification of production and its implications for your business.

Featured Posts

-

1 50

May 04, 2025

1 50

May 04, 2025 -

Analyzing Marvels Recent Struggles A Path Forward For The Mcu

May 04, 2025

Analyzing Marvels Recent Struggles A Path Forward For The Mcu

May 04, 2025 -

Dzhidzhi Khadid I Kuper Pervye Kommentarii Modeli Ob Otnosheniyakh

May 04, 2025

Dzhidzhi Khadid I Kuper Pervye Kommentarii Modeli Ob Otnosheniyakh

May 04, 2025 -

Gigi Hadid The Reason Behind Bradley Cooper And Leonardo Di Caprios Falling Out

May 04, 2025

Gigi Hadid The Reason Behind Bradley Cooper And Leonardo Di Caprios Falling Out

May 04, 2025 -

Wb Weather Update Heavy Rainfall Predicted For North Bengal

May 04, 2025

Wb Weather Update Heavy Rainfall Predicted For North Bengal

May 04, 2025