Electric Motor Independence: Strategies For Reducing China's Dominance

Table of Contents

China's dominance in the global electric motor manufacturing industry presents a significant geopolitical and economic challenge. This near-monopoly on production creates vulnerabilities for nations reliant on Chinese-made electric motors for everything from electric vehicles (EVs) to industrial automation. Achieving electric motor independence is no longer a luxury; it's a critical necessity for national security and economic stability. This article explores crucial strategies to lessen China's grip on this vital sector and build a more resilient future.

Diversifying the Electric Motor Supply Chain

Reducing dependence on a single source for electric motors requires a multifaceted approach to supply chain diversification. This involves strategic partnerships, reshoring/nearshoring initiatives, and the development of robust supplier networks.

Strategic Partnerships and Foreign Direct Investment

Building a resilient electric motor industry requires international collaboration. This means:

- Strategic alliances: Forming partnerships with reliable manufacturers in diverse geopolitical locations, sharing knowledge and resources to establish new production hubs.

- Incentivizing FDI: Offering attractive incentives—tax breaks, subsidies, streamlined regulations—to entice foreign companies with advanced electric motor technologies to invest in domestic production facilities.

- Joint ventures: Establishing joint ventures with technology leaders to leverage their expertise and accelerate the development of domestic capabilities. This fosters technology transfer and shared risk.

Reshoring and Nearshoring Manufacturing

Bringing electric motor production closer to home—or at least to friendly nations—mitigates risks associated with geopolitical instability and long supply chains. This involves:

- Reshoring incentives: Providing financial and logistical support to companies willing to relocate their electric motor production facilities back to their home countries.

- Nearshoring benefits: Encouraging the relocation of manufacturing to geographically proximate and politically stable partner countries.

- Infrastructure development: Investing in robust infrastructure, including skilled labor training programs and reliable energy grids, to support domestic manufacturing growth. This ensures a competitive and efficient environment.

Developing Robust Supplier Networks

Diversifying beyond the finished motor is crucial. This includes:

- Component sourcing: Identifying and securing alternative suppliers for critical components like copper windings, semiconductors, and permanent magnets.

- Domestic component production: Investing in the domestic production of these components, minimizing reliance on foreign suppliers.

- Rigorous quality control: Establishing comprehensive quality control measures throughout the entire supply chain to ensure high standards and reliability.

Fostering Technological Advancement in Domestic Electric Motor Production

Technological leadership is vital for electric motor independence. This requires significant investment in R&D, intellectual property protection, and workforce development.

Investing in R&D and Innovation

The race for superior electric motor technology demands continuous innovation. This means:

- Increased R&D funding: Substantially increasing government and private sector funding for research and development in advanced electric motor technologies.

- Next-generation motors: Supporting the development of next-generation electric motors with improved efficiency, power density, and durability.

- University collaborations: Partnering with universities and research institutions to foster collaboration and accelerate technological breakthroughs.

Protecting Intellectual Property

Protecting domestic innovations is crucial to maintaining a competitive edge. This involves:

- Strong IP protection: Implementing robust intellectual property protection laws and enforcement mechanisms.

- Preventing technology leakage: Implementing measures to prevent the theft or unauthorized transfer of sensitive technologies to competitors.

- Proprietary technology development: Prioritizing the development of unique and proprietary technologies to minimize dependence on foreign expertise.

Skill Development and Workforce Training

A skilled workforce is essential for a thriving electric motor industry. This requires:

- Targeted training programs: Investing in education and training programs to develop a highly skilled workforce capable of designing, manufacturing, and maintaining advanced electric motors.

- Talent attraction and retention: Implementing strategies to attract and retain talented engineers, technicians, and researchers in the electric motor sector.

- Industry-academia partnerships: Collaborating with vocational schools and universities to create tailored training programs that meet the specific needs of the industry.

Addressing the Rare Earth Element Challenge

Rare earth elements (REEs), particularly neodymium, are critical for high-performance electric motor magnets. China's dominance in REE mining and processing poses a significant challenge.

Securing Reliable Sources of Rare Earth Minerals

Reducing reliance on China for REEs requires a multi-pronged approach:

- Diversified sourcing: Identifying and securing reliable sources of REEs from diverse geopolitical locations to mitigate supply chain disruptions.

- Alternative materials: Investing in research and development of alternative materials and magnet designs that minimize or eliminate the need for rare earth elements.

- Domestic REE production: Developing domestic rare earth mining and processing capabilities to enhance self-sufficiency.

Developing Recycling and Reuse Technologies

A circular economy approach is crucial for sustainable REE management:

- Recycling R&D: Investing heavily in research and development of efficient and cost-effective rare earth recycling technologies.

- End-of-life recycling: Implementing policies and programs to encourage the collection and recycling of rare earth-containing materials from end-of-life electric motors.

- Circular economy promotion: Promoting a circular economy model to minimize waste and maximize the reuse of valuable resources.

Conclusion

Achieving electric motor independence is a complex undertaking that demands a holistic strategy. By diversifying supply chains, fostering technological innovation, securing access to critical raw materials, and investing in human capital, nations can significantly reduce their reliance on China and mitigate the associated risks. This is not merely about economic competitiveness; it’s about national security and building a more resilient and sustainable future for the electric vehicle and broader industrial automation sectors. Don't wait for a crisis; start planning your strategy for electric motor independence today.

Featured Posts

-

A Stronger Reform The Argument For Rupert Lowe

May 04, 2025

A Stronger Reform The Argument For Rupert Lowe

May 04, 2025 -

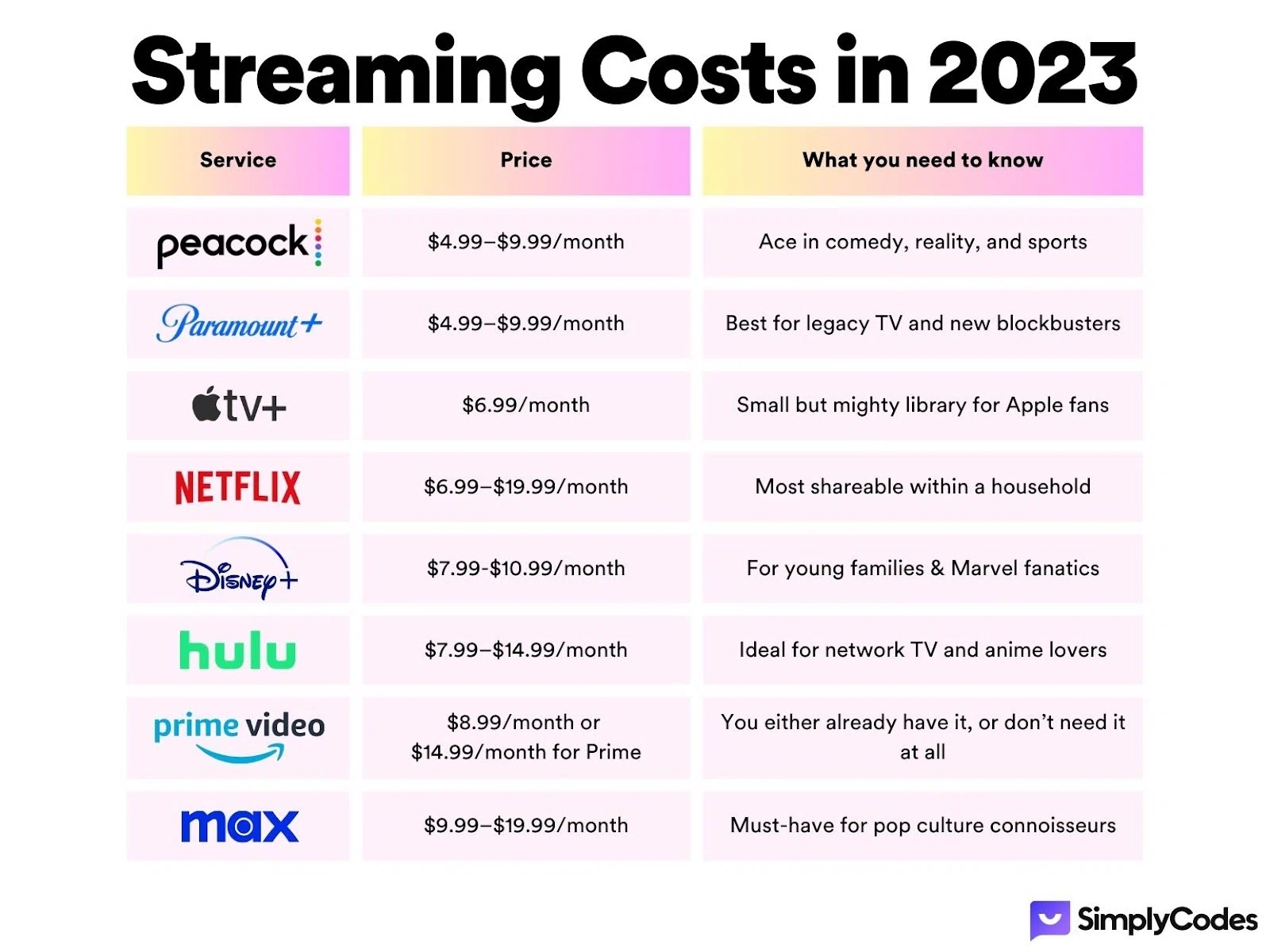

Kentucky Derby 2025 Online Streaming Costs Availability And Service Comparison

May 04, 2025

Kentucky Derby 2025 Online Streaming Costs Availability And Service Comparison

May 04, 2025 -

Will Renewed Ow Subsidies Attract More Bidders In The Netherlands

May 04, 2025

Will Renewed Ow Subsidies Attract More Bidders In The Netherlands

May 04, 2025 -

Sydney Sweeneys Solo Hotel Stay Fuels Breakup Speculation With Fiance Jonathan Davino

May 04, 2025

Sydney Sweeneys Solo Hotel Stay Fuels Breakup Speculation With Fiance Jonathan Davino

May 04, 2025 -

Analyst Chris Fallica On Trump And Putin A Strong Rebuke

May 04, 2025

Analyst Chris Fallica On Trump And Putin A Strong Rebuke

May 04, 2025