Challenges And Solutions In Automated Visual Inspection Of Lyophilized Drug Products

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Drug Products

Lyophilized drug products, due to their freeze-drying process, present a unique set of challenges for automated visual inspection. The inherent variability in appearance, coupled with the need for high sensitivity to detect subtle defects, necessitates advanced technologies to ensure accurate and reliable inspection.

Variations in Appearance and Morphology

Lyophilized cakes exhibit natural variability in their appearance, including cracks, fissures, and color variations. These variations often make it difficult to establish clear acceptance criteria for automated systems, leading to false positives (rejecting acceptable products) or false negatives (accepting defective products).

- Examples of visual defects: Cracking, collapse, sticking, discoloration, uneven surface.

- Difficulty in differentiation: Distinguishing between acceptable variations in appearance and actual defects requires sophisticated algorithms and image analysis techniques. The subtle nature of some defects makes them particularly challenging to detect reliably.

Subtle Defects and High Sensitivity Requirements

Detecting even minor defects, such as small cracks, pinholes, or foreign particles, is crucial for maintaining product quality and patient safety. Automated visual inspection systems must possess high sensitivity to identify these subtle defects reliably. However, achieving high sensitivity without generating an excessive number of false positives is a significant challenge. The choice of lighting and image acquisition parameters significantly impacts defect detection.

- Examples of subtle defects: Small cracks, pinholes, particulate matter, minor discolorations.

- Importance of high-resolution imaging and advanced algorithms: High-resolution cameras and advanced image processing techniques are necessary to capture and analyze subtle defects effectively.

Fragility and Handling of Lyophilized Products

Lyophilized products are inherently fragile. Automated handling systems must be designed to minimize the risk of damage during transportation and positioning for inspection. The delicate nature of these products requires gentle and precise robotic systems capable of handling them without causing breakage or compromising their integrity.

- Risks of breakage during automated handling: Improper handling can lead to product damage, rendering it unusable.

- Requirements for specialized robotic systems and handling mechanisms: Specialized robotic systems with soft grippers and precise movement control are necessary to prevent damage during automated handling.

Solutions and Technological Advancements

Overcoming the challenges of automated visual inspection of lyophilized drug products requires a multi-faceted approach incorporating advanced imaging techniques, artificial intelligence (AI), machine learning (ML), and sophisticated robotic systems.

Advanced Imaging Techniques

Employing advanced imaging techniques significantly enhances defect detection capabilities. High-resolution imaging provides detailed views of the product's surface, while multispectral and hyperspectral imaging can reveal subtle variations in color and composition that might be invisible to the naked eye or standard cameras. 3D imaging offers detailed surface analysis, allowing for the detection of defects that are not readily apparent in 2D images. Careful consideration of light sources and illumination techniques is also crucial for optimal image acquisition.

- Benefits of hyperspectral imaging: Hyperspectral imaging can differentiate between materials based on their spectral signatures, enabling the detection of subtle defects invisible to standard color cameras.

- Advantages of 3D imaging for surface analysis: 3D imaging provides a comprehensive view of the product's surface topography, facilitating the identification of cracks, fissures, and other three-dimensional defects.

Artificial Intelligence and Machine Learning

AI and ML algorithms play a crucial role in improving the accuracy and efficiency of automated visual inspection systems. Deep learning models, in particular, are effective in classifying defects and predicting potential quality issues. The development and implementation of these algorithms require extensive training datasets and data augmentation techniques to handle the variability inherent in lyophilized products.

- Examples of AI/ML applications: Defect classification, anomaly detection, prediction of potential quality issues.

- Advantages of deep learning models in handling variations: Deep learning models are robust and can adapt to the inherent variability in the appearance of lyophilized cakes, leading to improved accuracy and reduced false positives.

Robotic Systems and Automation

Integrating advanced vision systems with robotic arms is crucial for automating the entire inspection process. Gentle and precise robotic manipulators are essential for handling the fragile lyophilized products without causing damage. These systems should be capable of automated picking, placing, and positioning of the vials for inspection, enabling high-throughput inspection.

- Features of suitable robotic systems: Soft grippers, precise movement control, high repeatability, compatibility with vision systems.

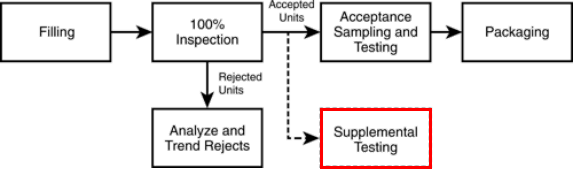

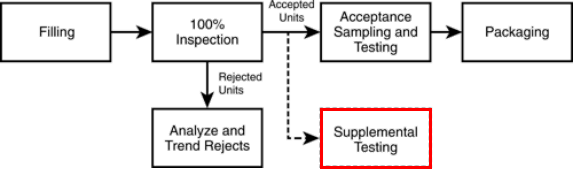

- Integration of vision systems for automated defect detection and rejection: Automated systems can detect defects and automatically reject defective products, improving efficiency and reducing manual intervention.

Conclusion

Automated visual inspection of lyophilized drug products presents significant challenges, primarily due to variations in appearance, subtle defects, and product fragility. However, by leveraging advanced imaging techniques, AI/ML algorithms, and sophisticated robotic systems, these challenges can be effectively addressed. Implementing these advanced technologies is crucial for ensuring the quality and safety of lyophilized drug products, improving manufacturing efficiency, and meeting stringent regulatory requirements. To learn more about optimizing your automated visual inspection processes for lyophilized products, contact us today.

Featured Posts

-

Alterya Acquired By Chainalysis Expanding Blockchains Ai Capabilities

May 11, 2025

Alterya Acquired By Chainalysis Expanding Blockchains Ai Capabilities

May 11, 2025 -

Tam Krwz Ky Nyy Mhbt 36 Salh Adakarh Ke Sath Rshte Ky Khany

May 11, 2025

Tam Krwz Ky Nyy Mhbt 36 Salh Adakarh Ke Sath Rshte Ky Khany

May 11, 2025 -

The Valspar Championship Lowrys Road To Contention

May 11, 2025

The Valspar Championship Lowrys Road To Contention

May 11, 2025 -

Final Home Game Victory Bayern Celebrate Bundesliga Win With Muller

May 11, 2025

Final Home Game Victory Bayern Celebrate Bundesliga Win With Muller

May 11, 2025 -

Bilan La Roue De La Fortune 3 Mois D Antenne Quel Bilan D Audience

May 11, 2025

Bilan La Roue De La Fortune 3 Mois D Antenne Quel Bilan D Audience

May 11, 2025