Advanced Techniques In Automated Visual Inspection Of Lyophilized Pharmaceutical Vials

Table of Contents

Image Acquisition and Enhancement for Improved Defect Detection

High-quality image acquisition is the foundation of effective automated visual inspection of lyophilized pharmaceutical vials. Subtle defects, such as cracks, particulate matter, and vial imperfections, can significantly impact product quality and patient safety. Advanced imaging techniques and image processing algorithms are essential for reliable detection.

High-Resolution Imaging Techniques

Various imaging modalities offer distinct advantages in detecting subtle defects. The choice depends on the specific needs and the types of defects to be identified.

- High-Resolution Cameras: Employing cameras with resolutions exceeding 12 megapixels provides the detail needed to identify minute particles and surface imperfections. CMOS and CCD sensors are commonly used, each with its own strengths regarding speed and sensitivity.

- Multispectral Imaging: This technique utilizes multiple wavelengths of light to capture images, providing information beyond the visible spectrum. This can improve the contrast and visibility of certain defects that might be difficult to detect with standard visible light imaging.

- Lighting Techniques: Proper lighting is crucial. Coaxial lighting minimizes shadows, while diffuse lighting provides uniform illumination, improving the visibility of subtle surface defects. Careful control of light intensity and angle is critical for optimal image acquisition.

Advanced Image Processing Algorithms

Advanced image processing algorithms significantly enhance the reliability of defect detection by improving the quality of the acquired images and enhancing the contrast of defects.

- Noise Reduction: Algorithms like Wiener filtering effectively reduce noise introduced during image acquisition, improving the signal-to-noise ratio and making defects easier to identify.

- Contrast Enhancement: Techniques like histogram equalization improve the contrast between defects and their surroundings, enhancing their visibility.

- Edge Detection: Algorithms such as the Sobel operator highlight the edges of defects, facilitating their identification and measurement. These algorithms help to isolate and quantify even microscopic defects.

Artificial Intelligence (AI) and Machine Learning (ML) in Automated Visual Inspection

AI and ML are transforming automated visual inspection of lyophilized pharmaceutical vials, offering unprecedented levels of accuracy and efficiency. Deep learning models, in particular, have proven particularly effective in this application.

Deep Learning for Defect Classification

Convolutional Neural Networks (CNNs) are at the forefront of AI-powered defect classification. These models can be trained to identify a wide range of defects with high accuracy.

- Particulate Matter Identification: CNNs can distinguish between different types of particulate matter (e.g., fibers, crystals, glass fragments) based on their size, shape, and optical properties.

- Critical vs. Non-Critical Defect Classification: The models can be trained to distinguish between defects that pose a significant risk to product quality and safety and those that are less critical. This reduces the number of false positives, optimizing inspection efficiency.

Deep learning's advantage lies in its ability to learn complex patterns from large datasets, adapting to different vial types and defect characteristics far better than traditional rule-based systems.

Data Augmentation and Model Training

Training robust AI models requires large, high-quality datasets of images with labeled defects. Data augmentation techniques are vital when sufficient data is unavailable.

- Image Rotation, Scaling, and Translation: These techniques artificially increase the size of the training dataset by creating modified versions of existing images.

- Noise Injection: Adding controlled noise to images helps the model to become more robust and less sensitive to variations in image quality.

Addressing the challenges of obtaining and preparing sufficient training data is critical for the success of AI-powered automated visual inspection.

Integration and Automation for Enhanced Efficiency

Effective integration and automation are key to realizing the full potential of advanced visual inspection techniques. High-throughput systems coupled with robust data analytics provide comprehensive quality control.

High-Throughput Inspection Systems

Modern automated inspection systems are designed to handle large volumes of vials efficiently, significantly improving throughput compared to manual inspection.

- Robotic Systems: Robots are employed for automated vial handling, loading, and unloading, increasing speed and minimizing human error.

- Conveyor Belt Systems: Automated conveyor belts facilitate the smooth and continuous flow of vials through the inspection process.

- Automated Data Logging: All inspection results are automatically logged and stored, providing a comprehensive record for traceability and quality control. This seamless integration streamlines the entire process.

Data Analytics and Reporting

The data collected by automated inspection systems provides valuable insights into process performance and defect trends. This data-driven approach is crucial for continuous improvement.

- Dashboards and Reporting Tools: User-friendly dashboards provide clear visualizations of inspection results, including defect rates, types of defects, and location of defects.

- Root Cause Analysis: Data analytics helps identify the root causes of defects, enabling the implementation of corrective actions to prevent their recurrence. This proactive approach significantly improves overall quality control.

Conclusion

Advanced techniques in automated visual inspection, including high-resolution imaging, AI-powered defect classification, and efficient system integration, are revolutionizing the quality control of lyophilized pharmaceutical vials. By implementing these methods, pharmaceutical manufacturers can significantly improve the accuracy and speed of inspection, reducing the risk of product recalls, enhancing patient safety, and ultimately optimizing their manufacturing processes. Investing in these advanced technologies is crucial for maintaining competitiveness in the demanding pharmaceutical market. Consider exploring these advanced techniques to elevate your automated visual inspection of lyophilized pharmaceutical vials to the next level.

Featured Posts

-

Ryan Reynolds Mntn Imminent Ipo Launch

May 11, 2025

Ryan Reynolds Mntn Imminent Ipo Launch

May 11, 2025 -

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 11, 2025

Sylvester Stallone Action Thriller Armor Now Streaming Free

May 11, 2025 -

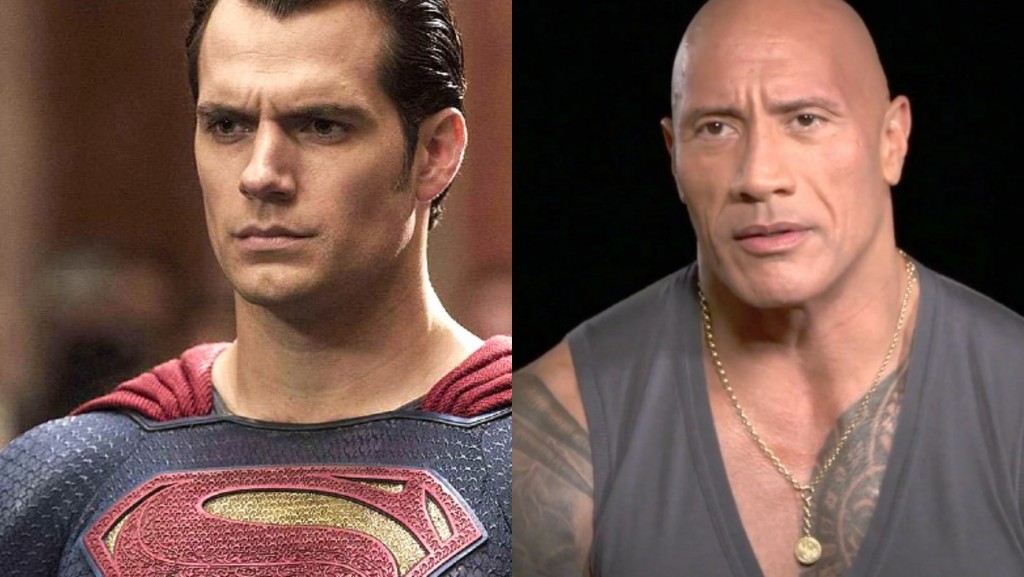

The Henry Cavill Superman Situation James Gunn Sheds Light On Past Decisions

May 11, 2025

The Henry Cavill Superman Situation James Gunn Sheds Light On Past Decisions

May 11, 2025 -

Lily Collins Sexy New Calvin Klein Campaign Photo 5133598

May 11, 2025

Lily Collins Sexy New Calvin Klein Campaign Photo 5133598

May 11, 2025 -

Instagrams Survival Strategy Ceos Testimony Highlights Tik Toks Impact

May 11, 2025

Instagrams Survival Strategy Ceos Testimony Highlights Tik Toks Impact

May 11, 2025